Double-crank driving double-point servo press

A technology of servo press and double-crank mechanism, which is applied in the field of double-point servo press and double-crank driven double-point servo press, which can solve the problems of poor manufacturing and assembly process, large comprehensive gap and complex structure, and achieve small comprehensive gap , high precision at the bottom dead point, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]

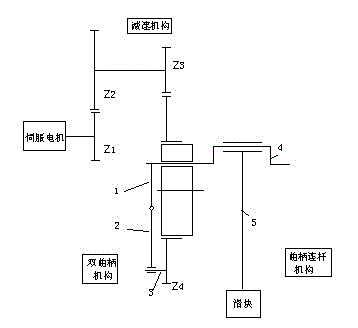

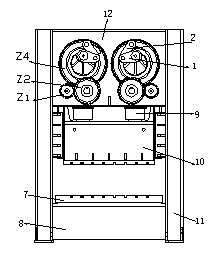

[0041] The transmission system of the double-crank driven double-point servo press of the present invention comprises a deceleration mechanism, a double-crank mechanism and a crank-link mechanism, such as figure 1 shown.

[0042] The deceleration mechanism is made up of one-stage or two-stage gears, and one-stage synchronous pulley and one-stage gear mechanism can also be selected. The final stage large gear Z4 of the deceleration mechanism is sleeved on the eccentric seat 6 fixed on the fuselage. The deceleration mechanism meets the requirements for the maximum number of strokes of the press under the condition of the rated speed of the servo motor.

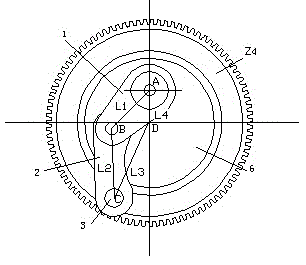

[0043] The double crank mechanism includes a large gear, a pin 3, a small connecting rod 2, an output rod 1 and an eccentric seat 6: the pin 3 is fixed on the rim of the large gear, one end of the small connecting rod 2 is hinged to the pin 3 and the other end is connected to the The output rod 1 is hinged, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com