Car frame

A vehicle frame and underframe technology, applied in the field of vehicle underframe design, can solve the problems of poor handling, reduced transmission efficiency, high fuel consumption, etc., and achieve the effects of strong climbing ability, increased load capacity, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

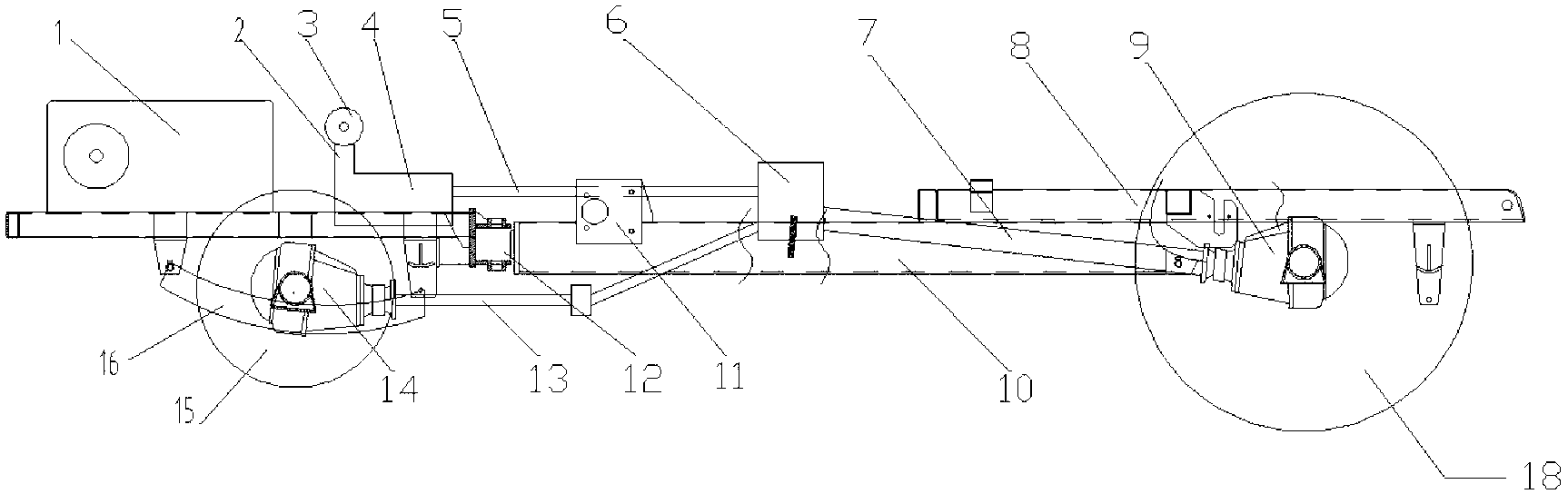

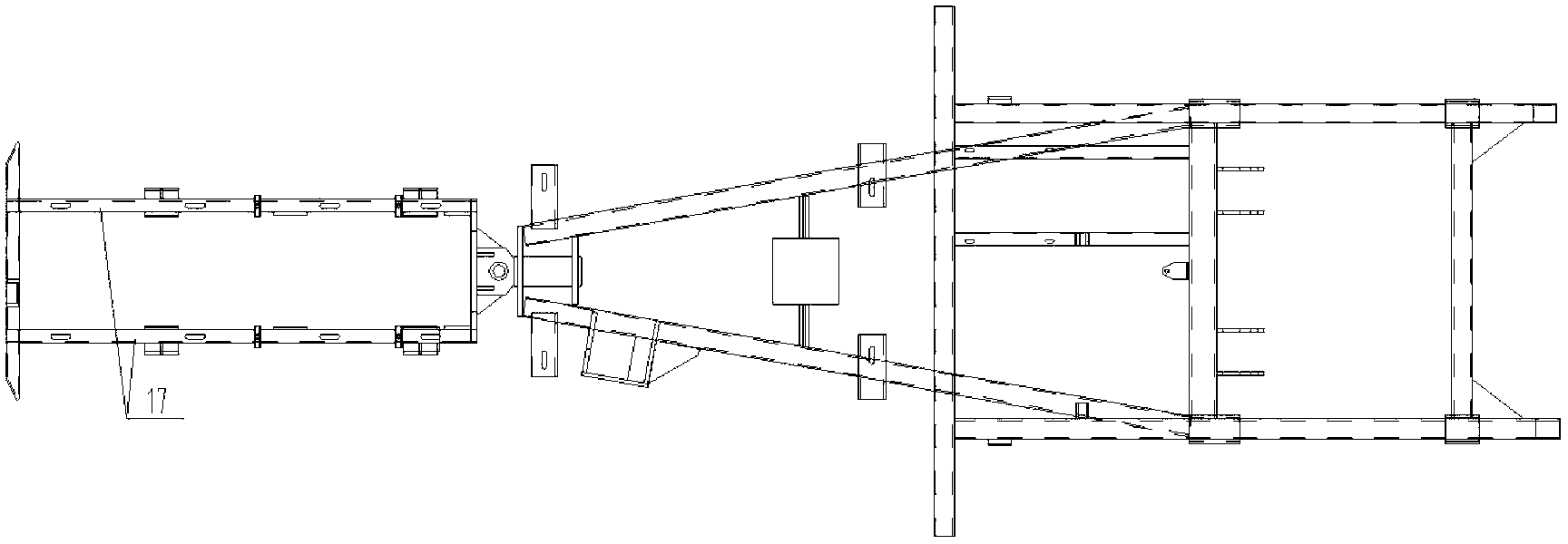

[0018] The frame includes left and right longitudinal beams (17), leaf springs (16), tractor (12), cab underframe (10) and rear underframe (8); wherein, the leaf springs (16) are Bow-shaped structure, fixed brackets and fixed underframes are respectively provided at the front and back of the bending point, and the fixed brackets and fixed underframes fix the leaf springs (16) on the left and right longitudinal beams (17); the left and right longitudinal beams (17) are respectively connected with cross beams at the front and rear , the rear beam is fixedly connected with the tractor (12); the tractor (12) can rotate horizontally, the rear of the tractor (12) is connected to the front of the cab chassis (10), and the rear of the cab chassis (10) The part is connected with the rear underframe (8).

[0019] Preferably, the front ends of the left and right longitudinal beams (17) are provided with an oil engine installation plate on which the engine is installed; the transmission (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap