Control system and control method for low temperature fluidizing chlorination furnace

A technology of a boiling chlorination furnace and a control system, which is applied in the field of low temperature boiling chlorination furnace, can solve the problems of high pressure and high temperature danger, and the staff cannot go to the site for operation at the first time, and achieve the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Various example embodiments will now be described more fully with reference to the accompanying drawings, in which some example embodiments are shown.

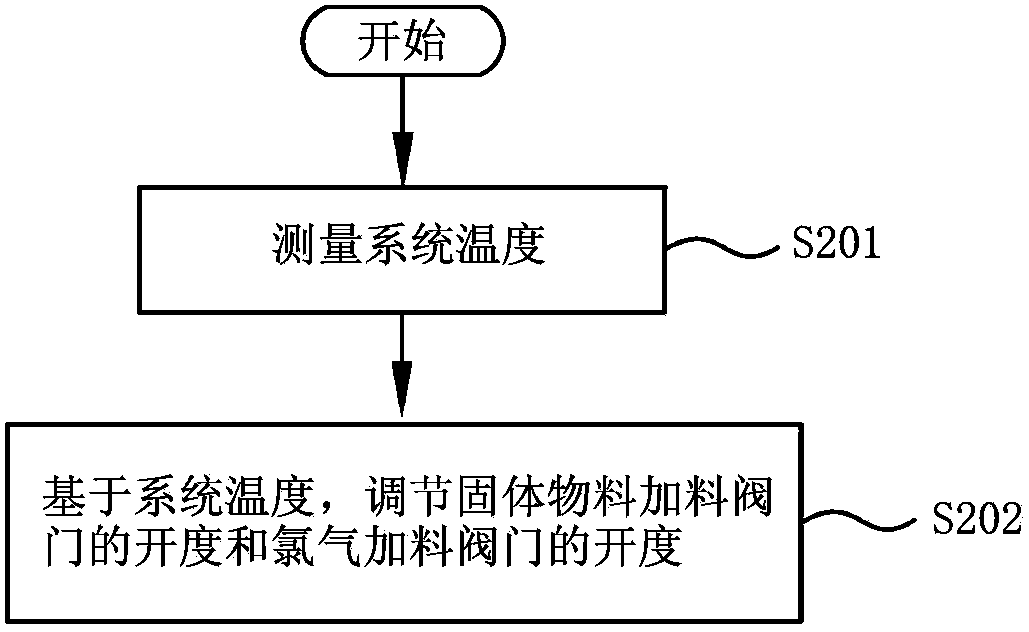

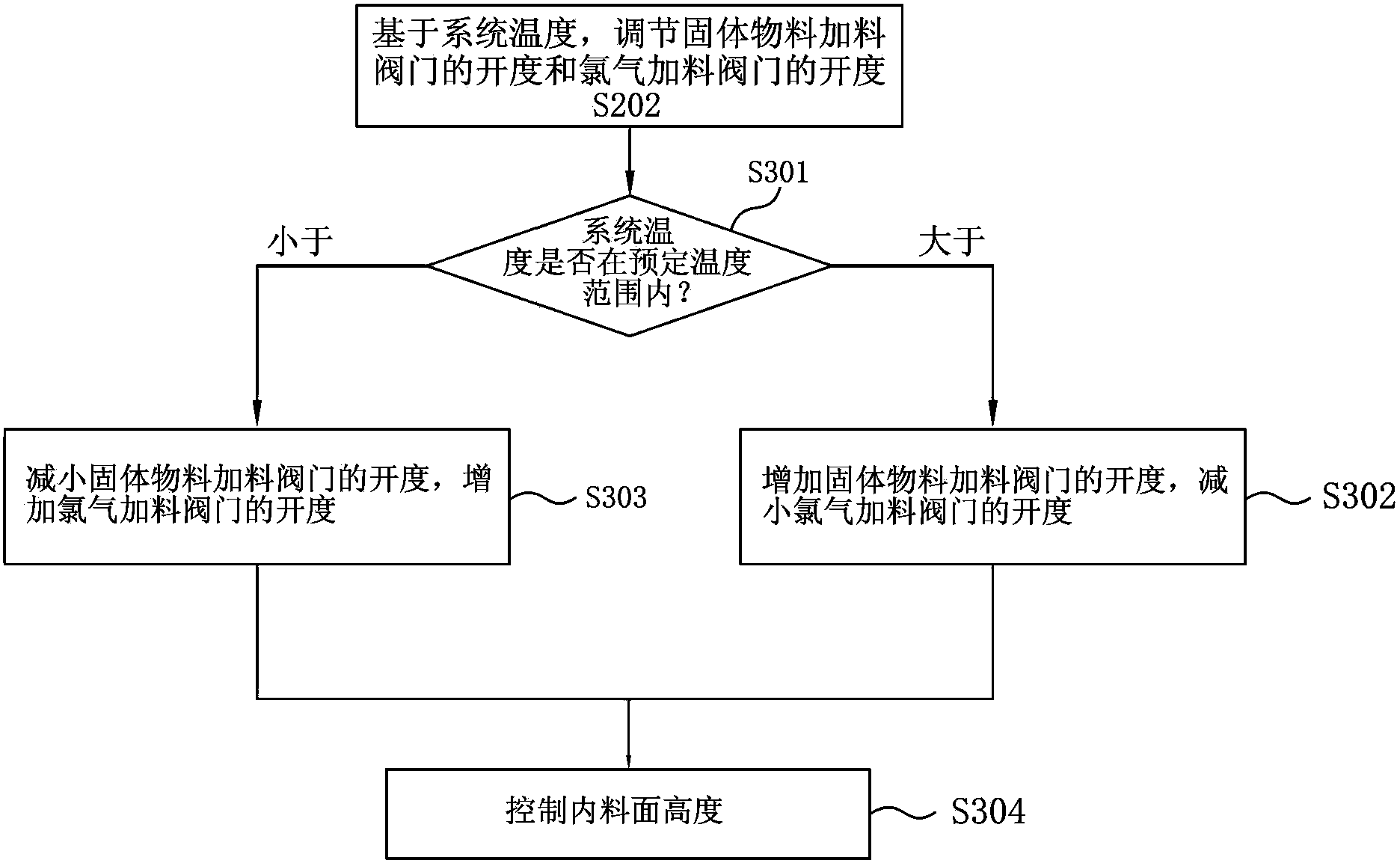

[0028] The control system for the low temperature boiling chlorination furnace of the present invention controls the system temperature of the low temperature boiling chlorination furnace through the solid material feeding valve and the chlorine gas feeding valve.

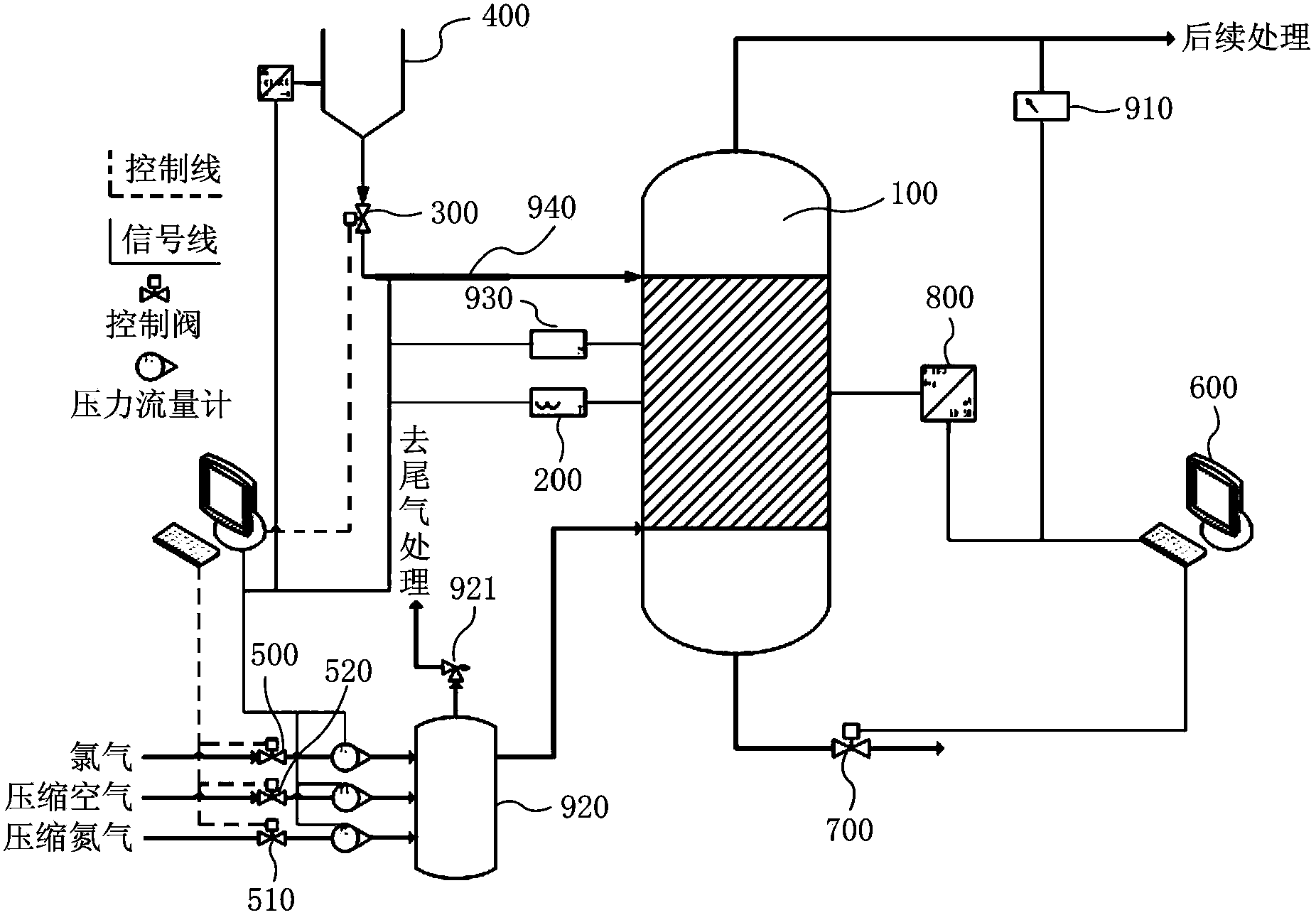

[0029] figure 1 is a control system for a low temperature boiling chlorination furnace according to an embodiment of the present invention.

[0030] The control system for the low-temperature fluidized chlorination furnace of the present invention includes a thermometer 200 , a solid material feeding valve 300 , a chlorine gas feeding valve 500 , and a controller 600 .

[0031] The thermometer 200 is installed in the low temperature boiling chlorination furnace 100, and can measure the system temperature in the low temperature boiling chlorination furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com