Sterilizer

A technology of disinfection machine and body, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of inconvenient use, achieve the effect of increasing sealing force and friendly man-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

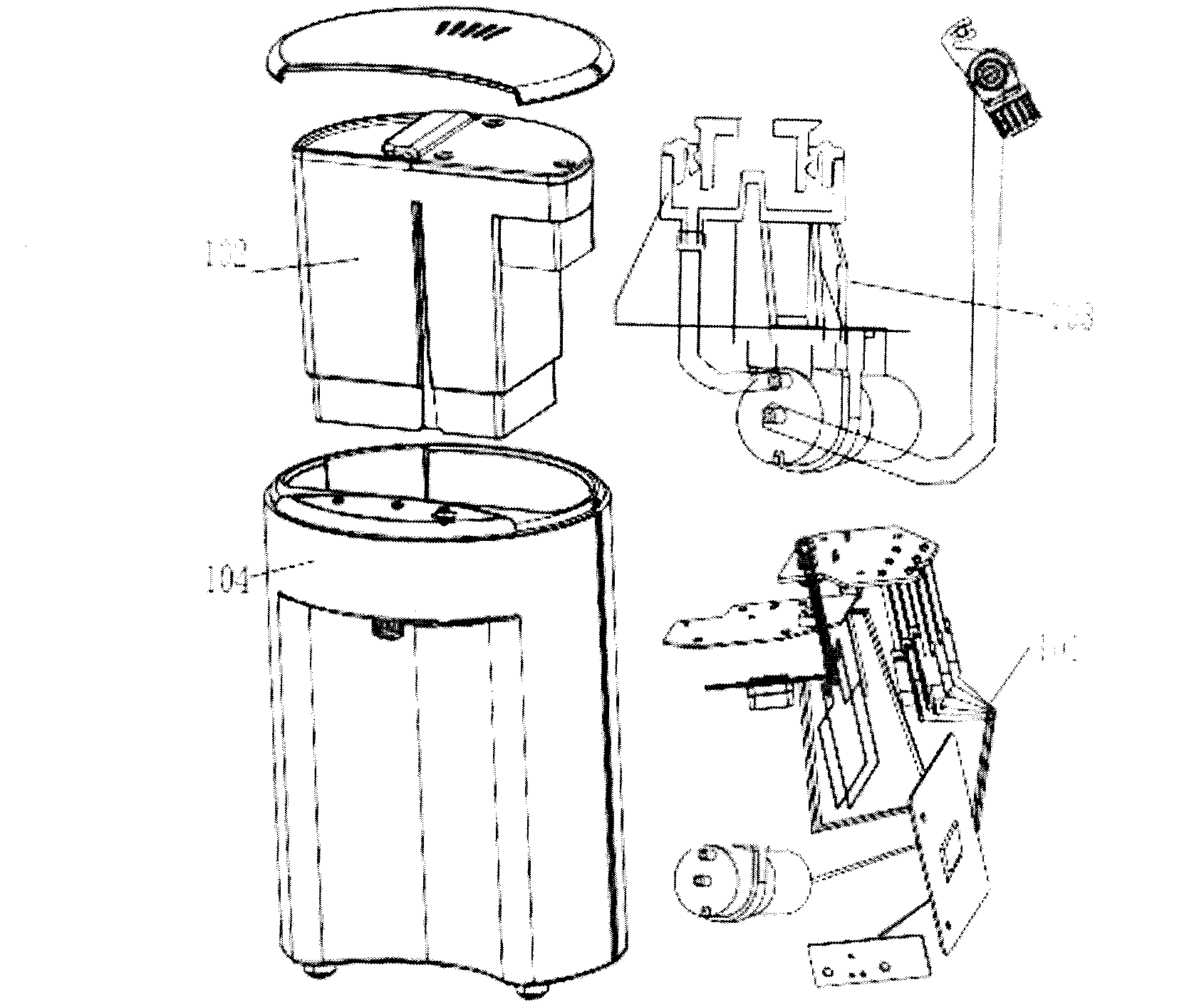

[0031] figure 1 As an embodiment of the present invention, the sterilizer includes a base assembly 104 , an electronic circuit assembly 101 , an electrolytic cell assembly 102 , and a liquid circuit assembly 103 . Wherein the electrolytic cell assembly 102 has two forms that can be separated or not separated from the sterilizer, figure 1 It is preferred that the solution is detachable.

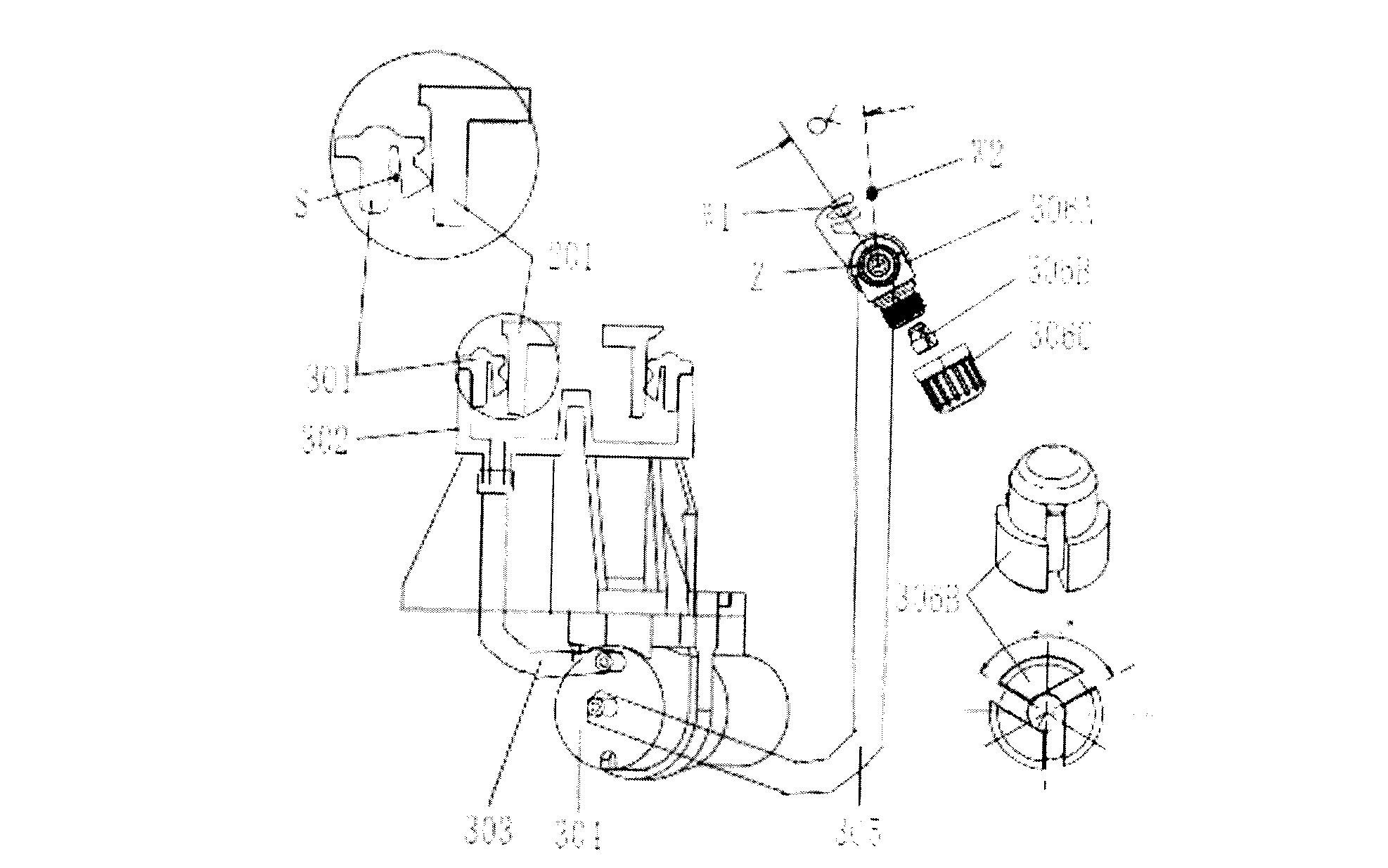

[0032] Figure 5 It is a structural diagram of the base assembly 104. The base assembly 104 includes an inner body 504, a front body 501, a rear body 502, an upper cover 503, a nozzle holder 505, a main board box 506, a base 507, and machine feet 508. The inner body 504 is provided with an inner cavity with an upward opening, and an upper cover covers the mouth of the inner cavity. The inner body 504, the front body 501, the rear body 502, and the base 507 form a closed outer cavity. The front body 501 is provided with a concave curved surface for the purpose of allowing hands to reach int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com