Method for growing crystals in crystal three-dimension motion solution

A technology for three-dimensional movement and crystal growth, which is applied in the directions of crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of affecting crystal quality, crystal growth speed and crystal quality, etc. The effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

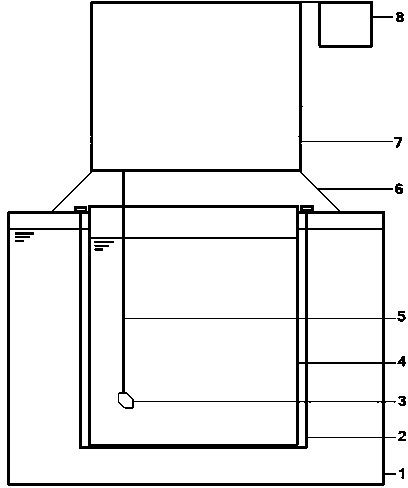

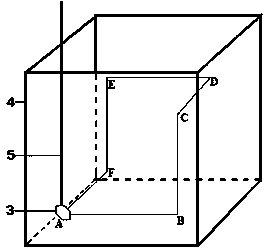

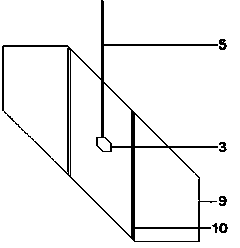

Image

Examples

Embodiment

[0019] This embodiment takes KDP crystal growth as an example, including five process steps of solution preparation, solution filtration, solution overheating, seed crystal fixation, and crystal three-dimensional motion growth. The specific steps are:

[0020] 1) Solution preparation: according to the solubility formula S t =13.76+0.359 t +0.0041 t 2 (where S t The unit is gKDP / 100mL water, t The unit is °C), the raw material required to prepare 10 L saturated solution at 55 °C is 4.59 kg, weigh this amount of high-grade pure raw material, add it to the measured 10 L double-distilled water, and prepare 10 L of saturated solution;

[0021] 2) Solution filtration: Filter the solution with a filter paper with a pore size of 0.45 μm and a filter membrane with a pore size of 0.22 μm to obtain a pure solution;

[0022] 3) Solution superheating: superheat the pure solution at 20°C above the saturation temperature, that is, at 75°C for 24 hours to obtain a growth solution;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com