Ultrasonic multipoint real-time monitoring method for mine surrounding rock top plate disasters

A real-time monitoring and ultrasonic technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., to achieve simple operation and post-analysis, real-time monitoring data, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

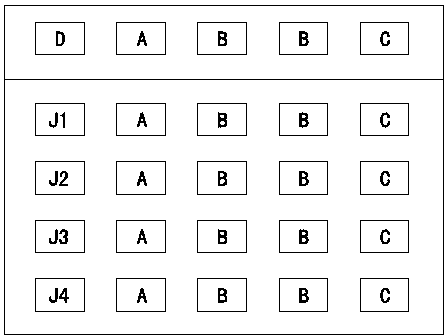

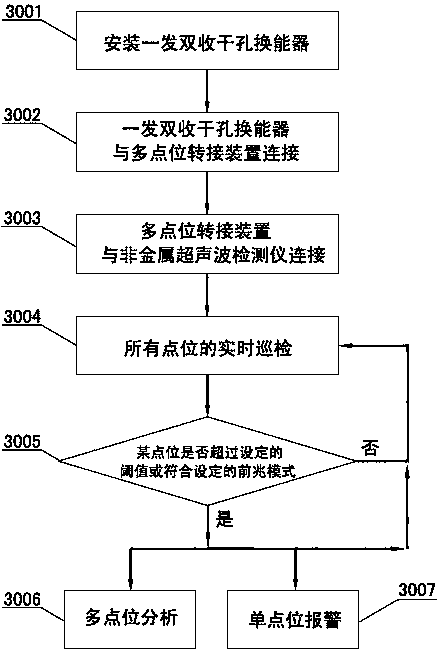

[0035] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

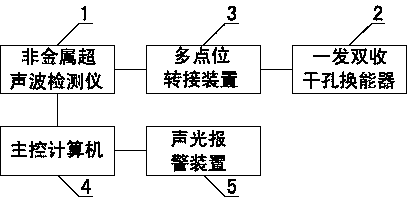

[0036] The mine surrounding rock roof disaster ultrasonic multi-point real-time monitoring method of the present invention, the hardware part is composed of the following parts: non-metallic ultrasonic detector 1, one-shot double-receive dry-hole transducer 2, multi-point switching device 3, Main control computer 4 and sound and light alarm device 5.

[0037] Such as figure 1 As shown, a plurality of one-shot double-receiver dry-hole transducers 2 are connected to the multi-point adapter device 3 through cables, and the multi-point adapter device 3 is connected to the non-metallic ultrasonic detector 1 through cables, and the non-metallic ultrasonic detector 1 is connected with the main control computer 4, and the main control computer 4 is connected with the sound and light alarm device 5 at the same time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com