Convection and fully-cooled type end cover structure for novel roots pump

A Roots pump and end cap technology, which is applied to the components of the pumping device for elastic fluid, pump components, rotary piston type/swing piston type pump components, etc., can solve acid gas corrosion, Roots pump inlet Vacuum loss, inconvenient disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

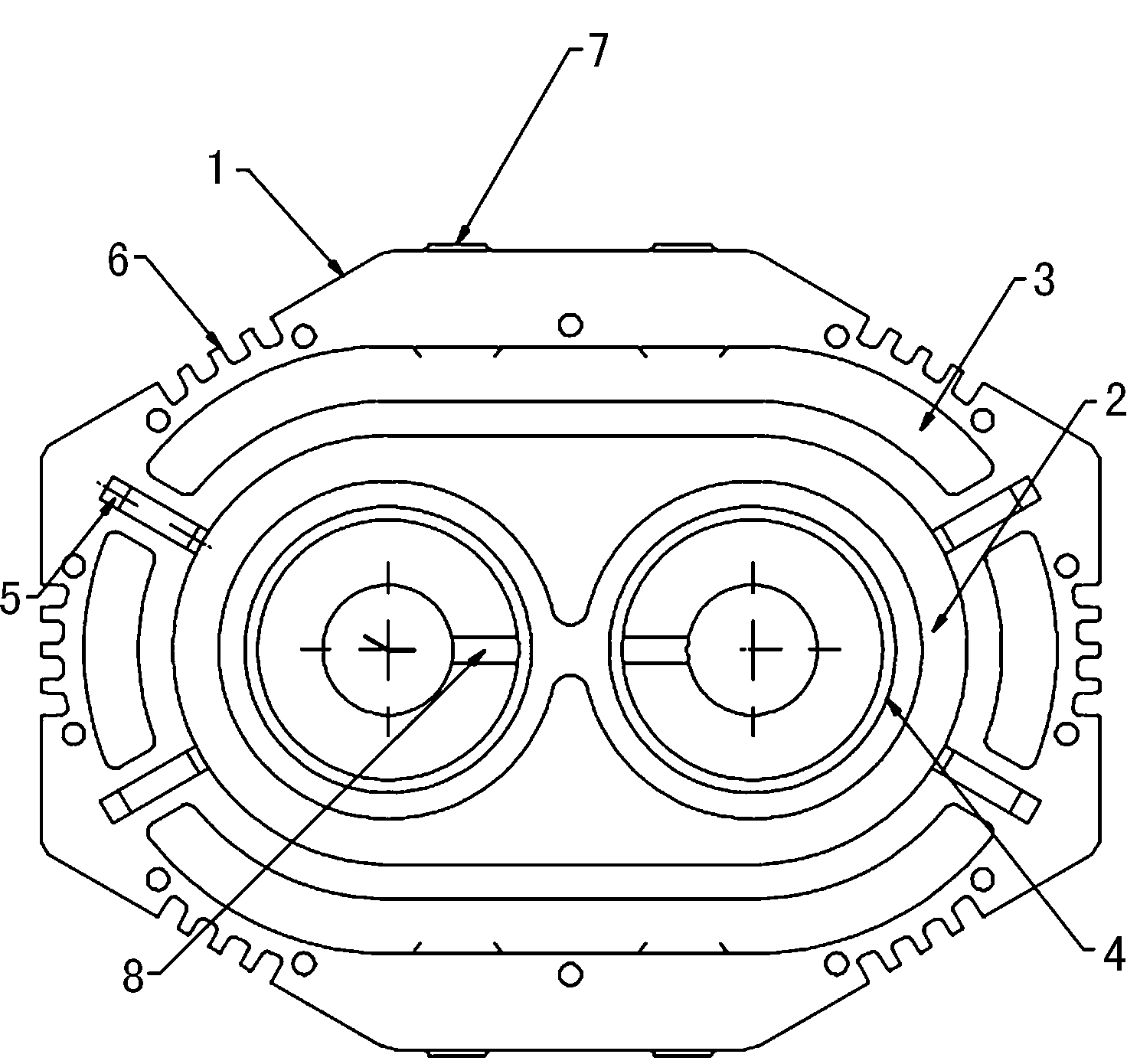

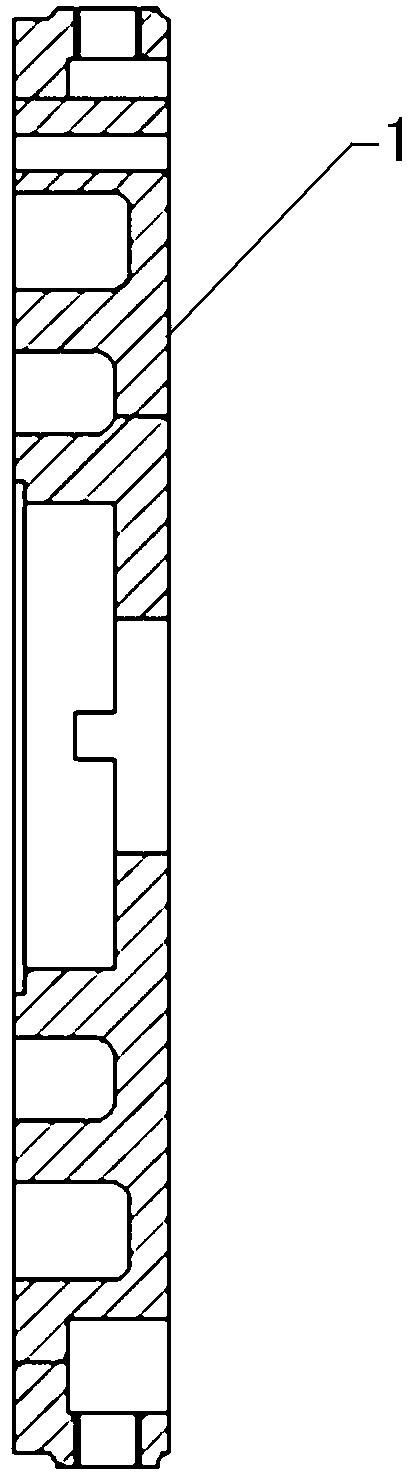

[0012] The invention discloses a convection full-cooling end cover structure for a new Roots pump, which includes an end cover body 1, which is different from the prior art in that: the end cover body 1 is geometrically octagonal, and the end cover body The inner cavity of the pump is elliptical, which can overcome the pressure of the inner cavity and balance the external force, and at the same time make the appearance of the Roots pump more beautiful and atmospheric.

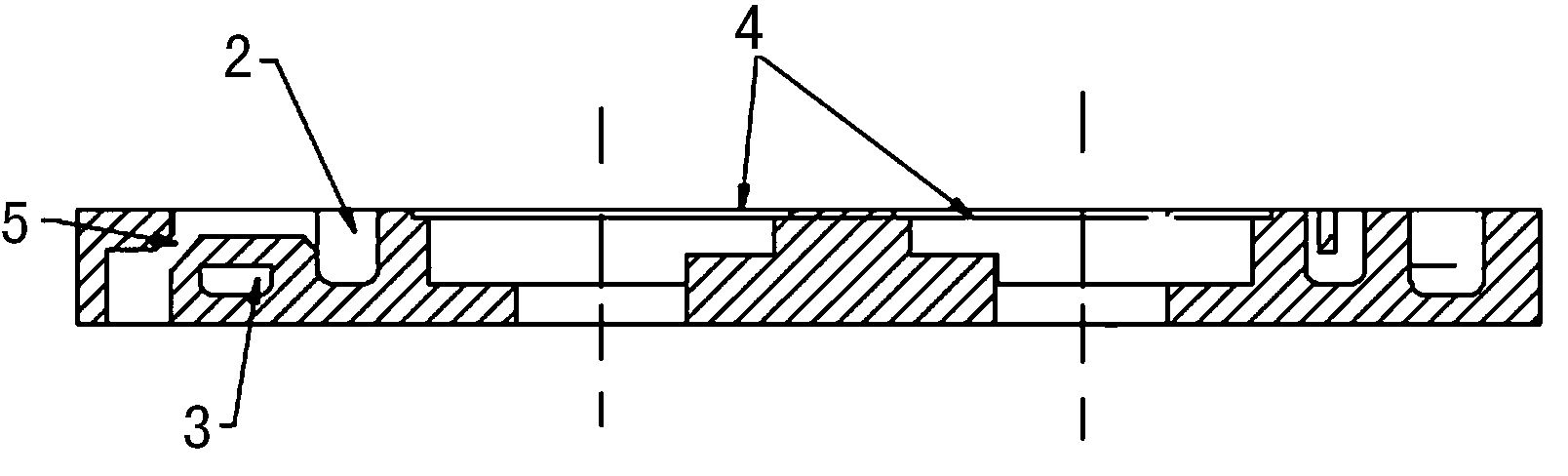

[0013] In specific implementation, the inner surface of the end cap body 1 forms an annular distribution of end cap inner cooling grooves 2, and the inner surface of the end cap body 1 outside the end cap inner cooling groove 2 forms an annular distribution of end cap outer cooling grooves 3, The end cover of the new Roots pump is designed with a special independent inner and outer two-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com