Sand control screen sand-blocking precision detecting device and detecting method

A sand control screen and accuracy detection technology, which is applied in the direction of measuring devices, mechanical parts testing, machine/structural parts testing, etc., can solve the problems of sand control screen sample test result errors, etc., to avoid errors and instability, The effect of reducing detection cost and improving stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

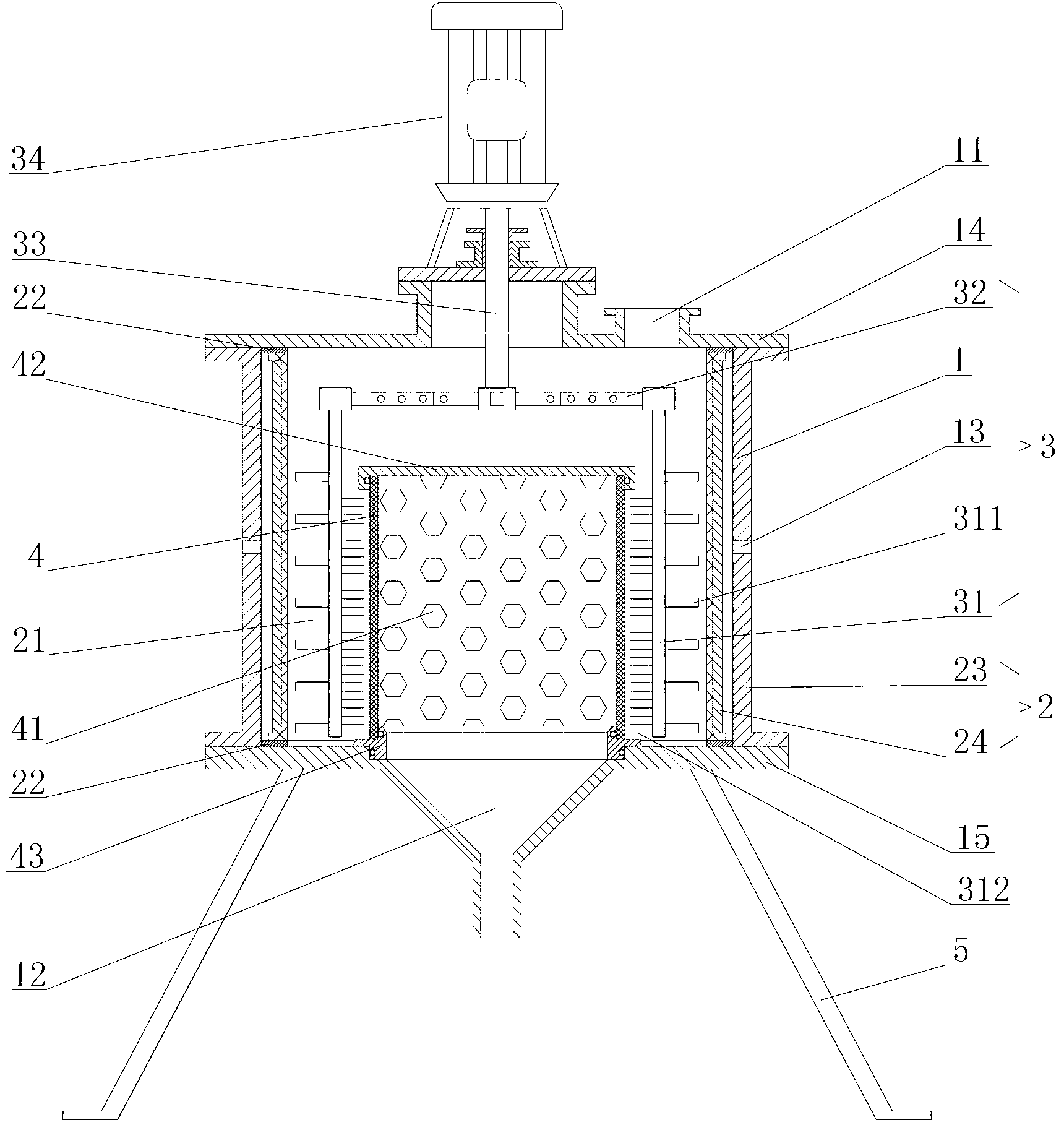

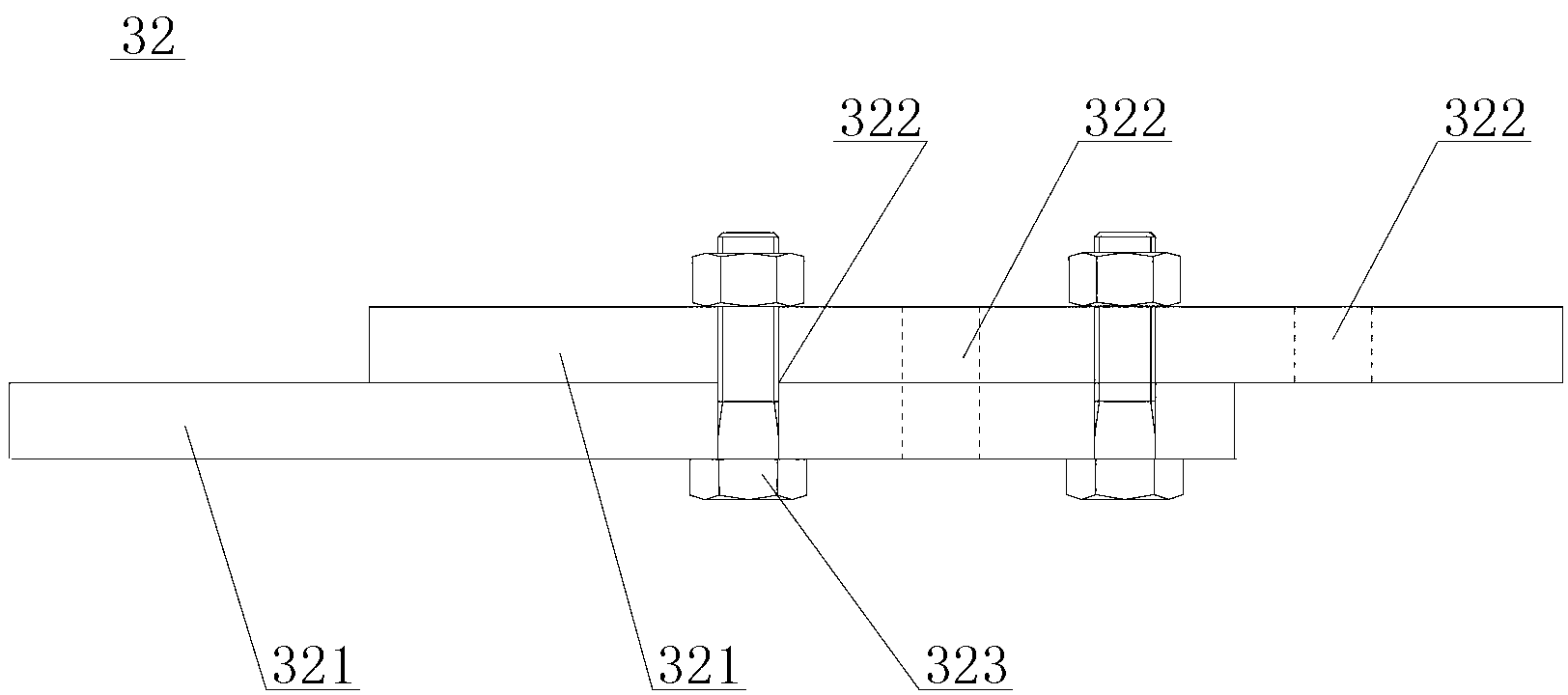

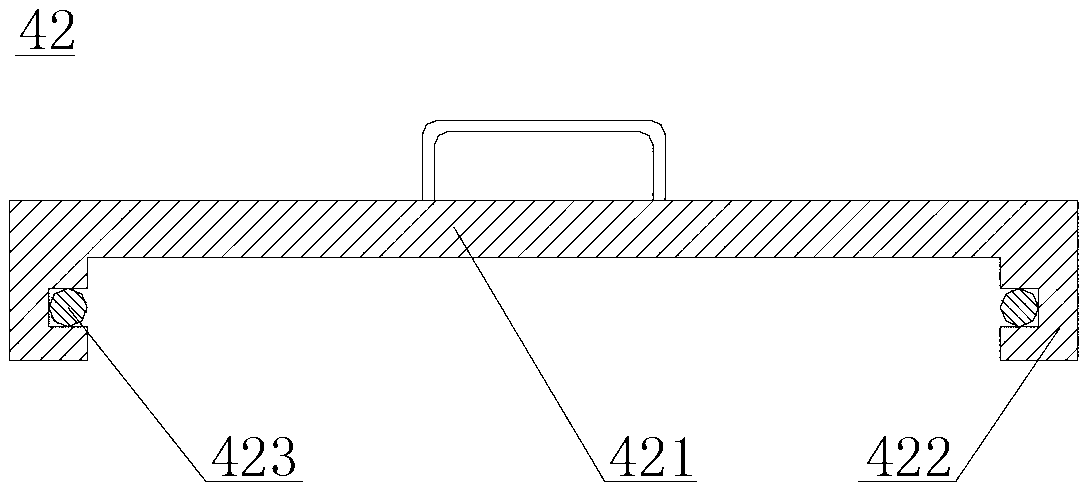

[0045] Such as figure 1As shown, the present invention provides a sand-retaining accuracy detection device of a sand control screen, which includes an autoclave body 1 , a distribution network pipe 2 and a stirring assembly 3 . Wherein: the upper end of the autoclave body 1 is provided with a sand filling port 11, and its lower end is provided with a liquid outlet 12, and a plurality of liquid inlet holes 13 are provided on the side wall of the autoclave body 1, and the contents of the autoclave body 1 A sand control screen sample 4 is placed, and the sand control screen sample 4 has a liquid outlet channel, and the liquid outlet channel is opposite to the liquid outlet 12; the shunt network pipe 2 is located in the autoclave body 1 and is sleeved on Outside the sand control screen sample 4, an annular space 21 is formed between the diversion network pipe 2 and the sand control screen sample 4, and the annular space 21 is filled with sand particles; the stirring assembly 3 is ...

Embodiment approach 2

[0061] see Figure 1-4 As shown, the present invention also provides a method for detecting sand-retaining accuracy of sand-control screens using the above-mentioned sand-retaining accuracy detection device for sand-control screens to detect sand-retaining accuracy of sand control screens. The method for detecting sand-retaining accuracy of sand control screens includes the following steps:

[0062] a) Cut a section of sand control screen sample 4 from the sand control screen to be tested, and put the sand control screen sample 4 into the autoclave body 1 of the sand control screen sand retaining accuracy detection device;

[0063] b) Selecting sand grains, the grain size of the sand grains ranges from 0.02 mm to 1.6 mm;

[0064] c) After mixing the selected sand particles with different particle sizes, put the sand control screen sample 4 and the shunt network pipe 2 in the autoclave body 1 from the sand filling port 11 of the autoclave body 1 In the annular space 21 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com