Damp removal and straightening experimental method for damp solid cables

An experimental method and solid technology, applied in the experimental field, can solve problems such as less research, and achieve the effect of convenient, accurate and high-efficiency detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

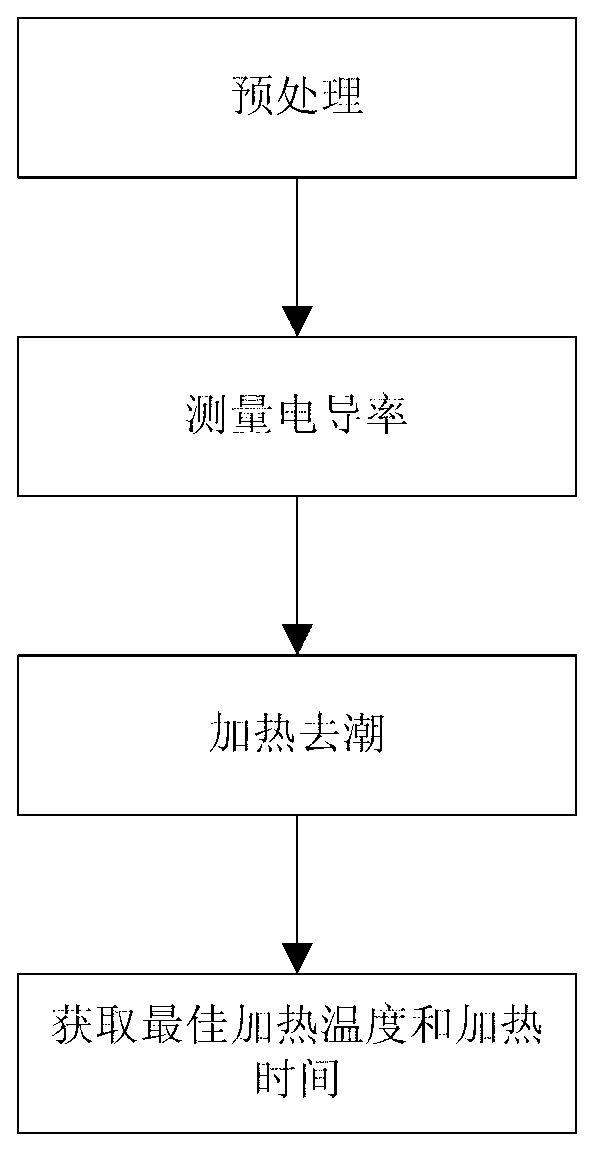

[0020] Such as figure 1 Shown, a kind of dehumidification straightening experiment method of wet solid cable, this method comprises the following steps:

[0021] 1) The wet solid cable to be tested and the new solid cable used as the alignment standard are pretreated so that the surface of the solid cable exposes a main insulation layer with a length of 5 cm as the measurement section. The measurement section of the wet solid cable to be tested is fully and uniformly sprayed with water to make it more conducive to reflecting the degree of humidity.

[0022] 2) Measure the conductivity of the wet solid cable to be tested and the measurement section on the new solid cable respectively, and the specific measurement method adopts the indirect measurement method. Firstly, input a DC voltage of 2000V at both ends of the measurement section, measure the surface leakage current of the solid cable, and obtain the conductivity of the solid cable through calculation of the surface leaka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com