Method for detecting epitaxial silicon defects

A technology of epitaxial silicon and defects, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as difficult to ensure accuracy, surface distribution detection of small defects, and silicon wafers can not continue to be used, etc., to achieve quantitative Determine the effect of degree and location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

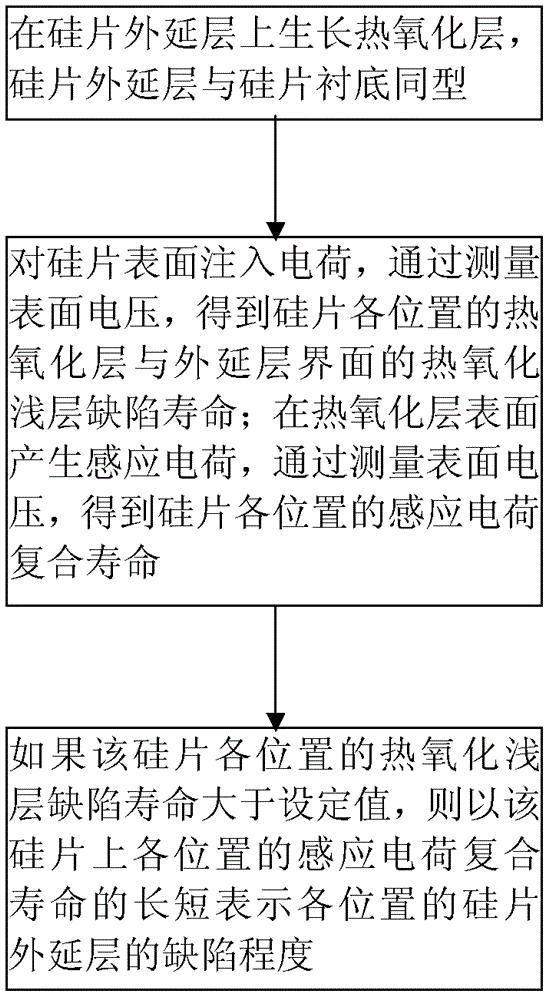

[0017] An embodiment of the method for detecting epitaxial silicon defects of the present invention is as follows: figure 1 as shown, including the following steps:

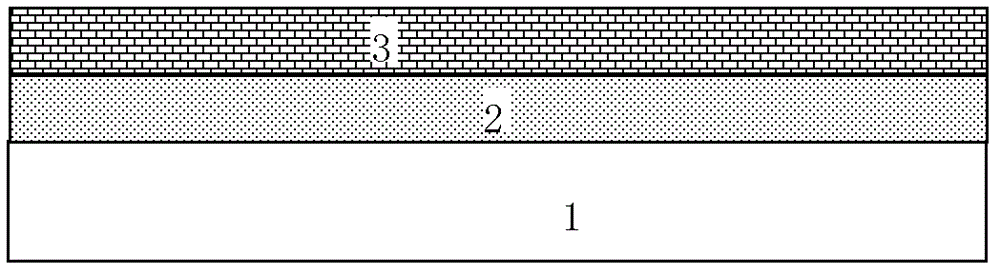

[0018] 1. The thermal oxide layer 3 is grown on the silicon wafer epitaxial layer 2, and the silicon wafer epitaxial layer 2 is the same type as the silicon wafer substrate 1 (both N-type or P-type), such as figure 2 shown;

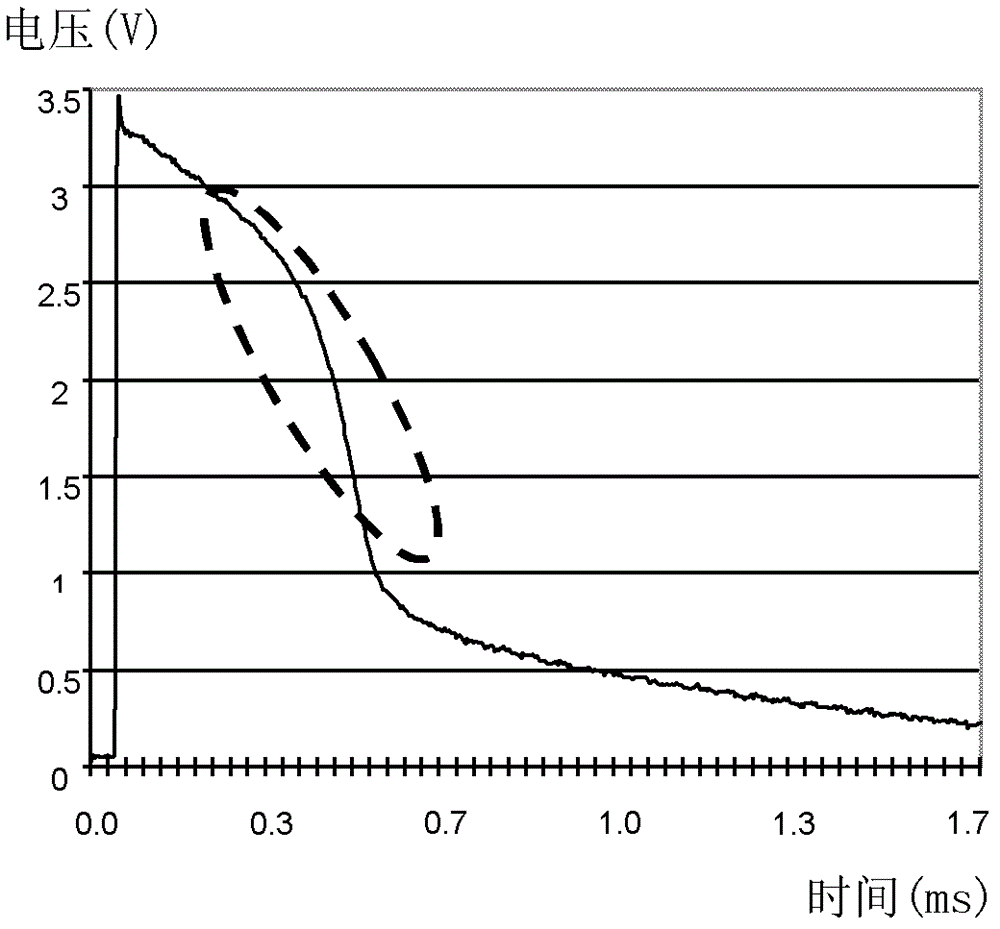

[0019] 2. Inject charges into the surface of the silicon wafer, and then measure the surface voltage to obtain the thermally oxidized shallow layer defect life of the interface between the thermally oxidized layer and the epitaxial layer at each position of the silicon wafer;

[0020] The induced charge is generated on the surface of the thermal oxide layer, and the recombination life of the induced charge at each position of the silicon wafer is also obtained by measuring the surface voltage;

[0021] 3. If the defect lifetime of the thermally oxidized shallow layer at each position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com