Method of temperature drift estimating and compensating in scanning probe microscopy

A technology of scanning probe and compensation method, applied in scanning probe technology, instruments, etc., can solve the problem of effectively calculating the temperature drift value, and achieve the effect of reducing human intervention and suppressing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

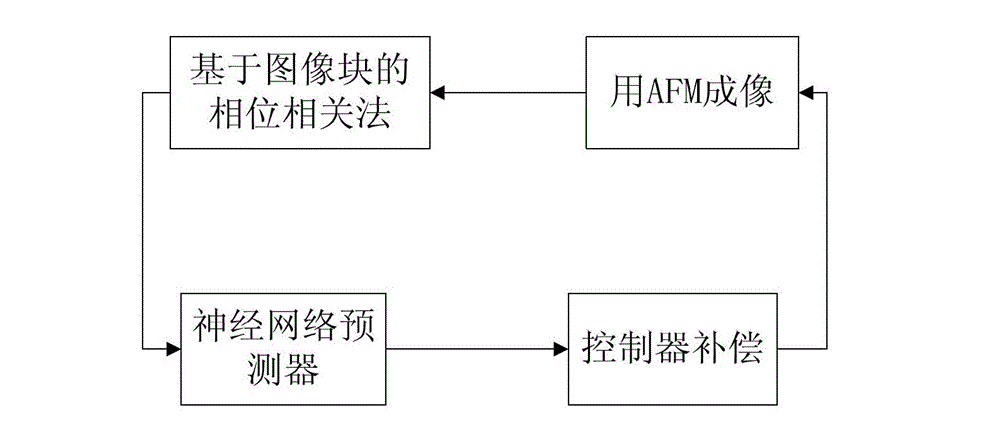

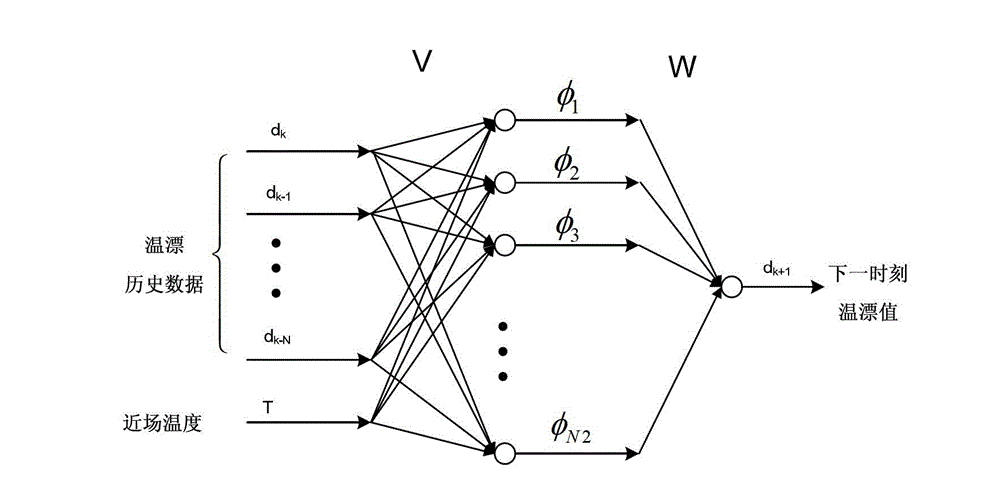

[0023] The method for estimating and compensating the temperature drift of the scanning probe microscope of the present invention comprises the following steps:

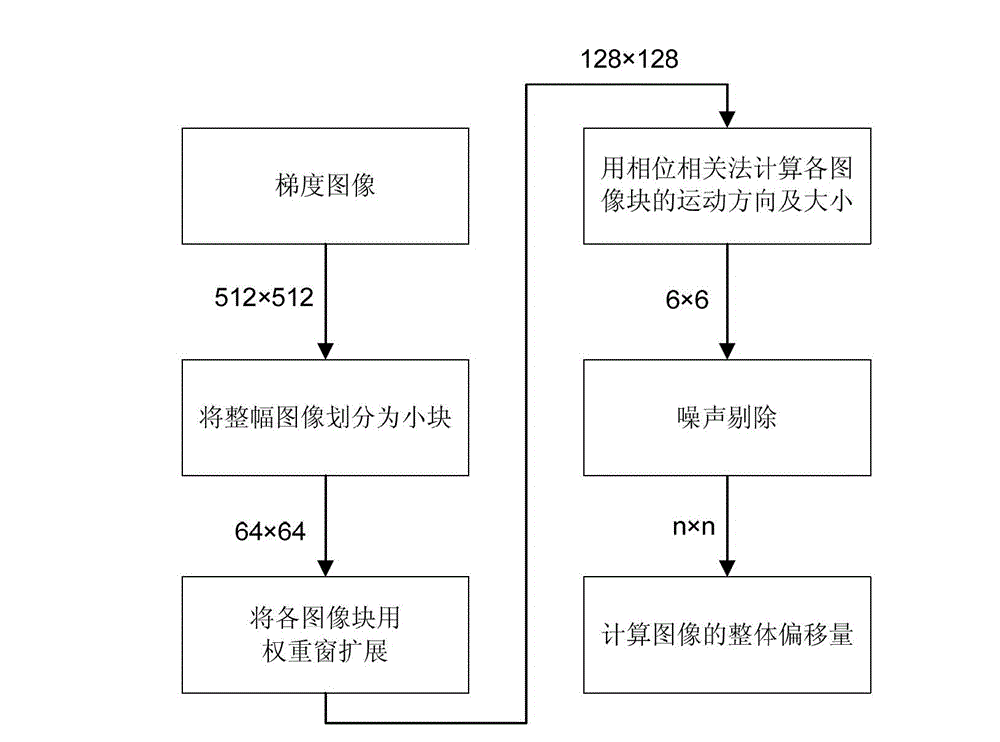

[0024] Step 1: Use a scanning probe microscope to obtain the height image of the sample surface at a fixed sampling interval. After each image is obtained, the height of each pixel is subtracted from the height of the adjacent pixel to obtain a gradient image of the sample surface , to eliminate the effect of z-drift.

[0025] Specifically, the relationship between the height images of the sample surface acquired at adjacent sampling moments can be written as h k+1 (x,y)=h k (x+Δx k ,y+Δy k )+Δz k , where h k (x, y) is the height value of the sample surface height image at point (x, y) acquired at the sampling time k, Δx k , Δy k , Δz k Represents the drift of the sample in the three directions of x, y, and z from the time of sampling k to the time of sampling k+1. Now introduce the gradient g k (x,y)=h k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com