Optical mutual inductor calibration and operation monitoring method and system

An optical transformer and operation monitoring technology, which is applied in the direction of instruments, measuring electricity, and measuring devices, can solve problems such as power outages in substations and inconvenient measurements, and achieve accurate real-time monitoring, fast speed, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the drawings.

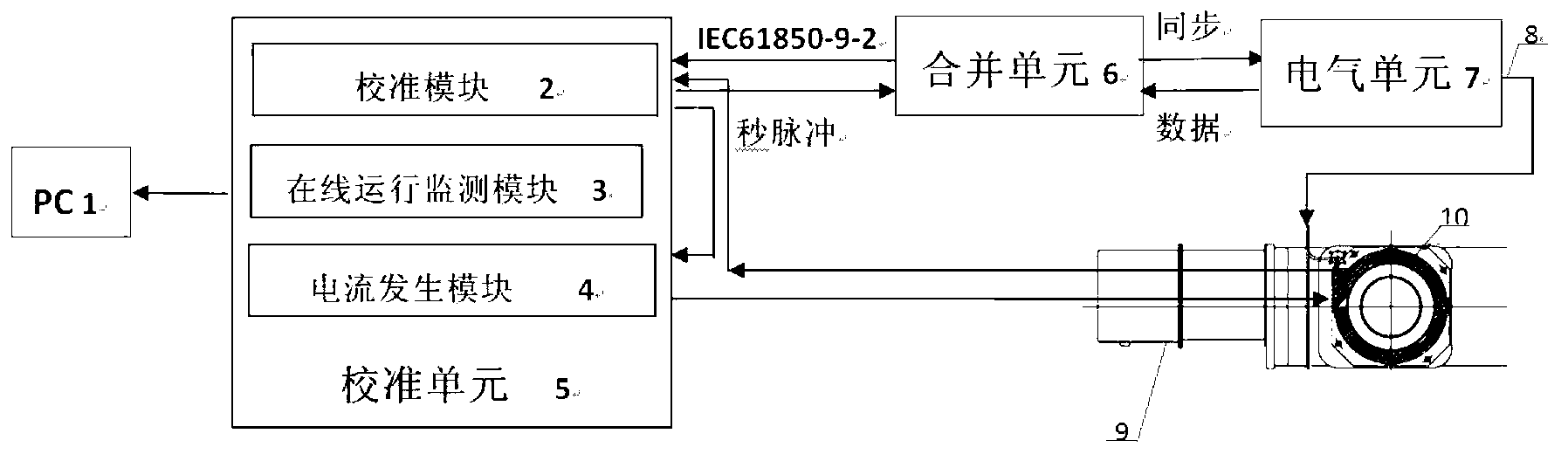

[0027] Such as figure 1 As shown, the optical transformer calibration and operation monitoring system of the present invention includes: a computer 1, a calibration unit 5, a merging unit 6, a CT electrical unit 7, a FOCT optical cable 8, a GIS 9, and an equal ampere-turn optical fiber sensitive ring 10. The calibration unit 5 includes a calibration module 2, an online operation monitoring module 3, and a current generation module 4. The GIS9 is a gas-insulated combined electrical equipment, which is used to install an equal ampere-turn optical fiber sensitive ring 10.

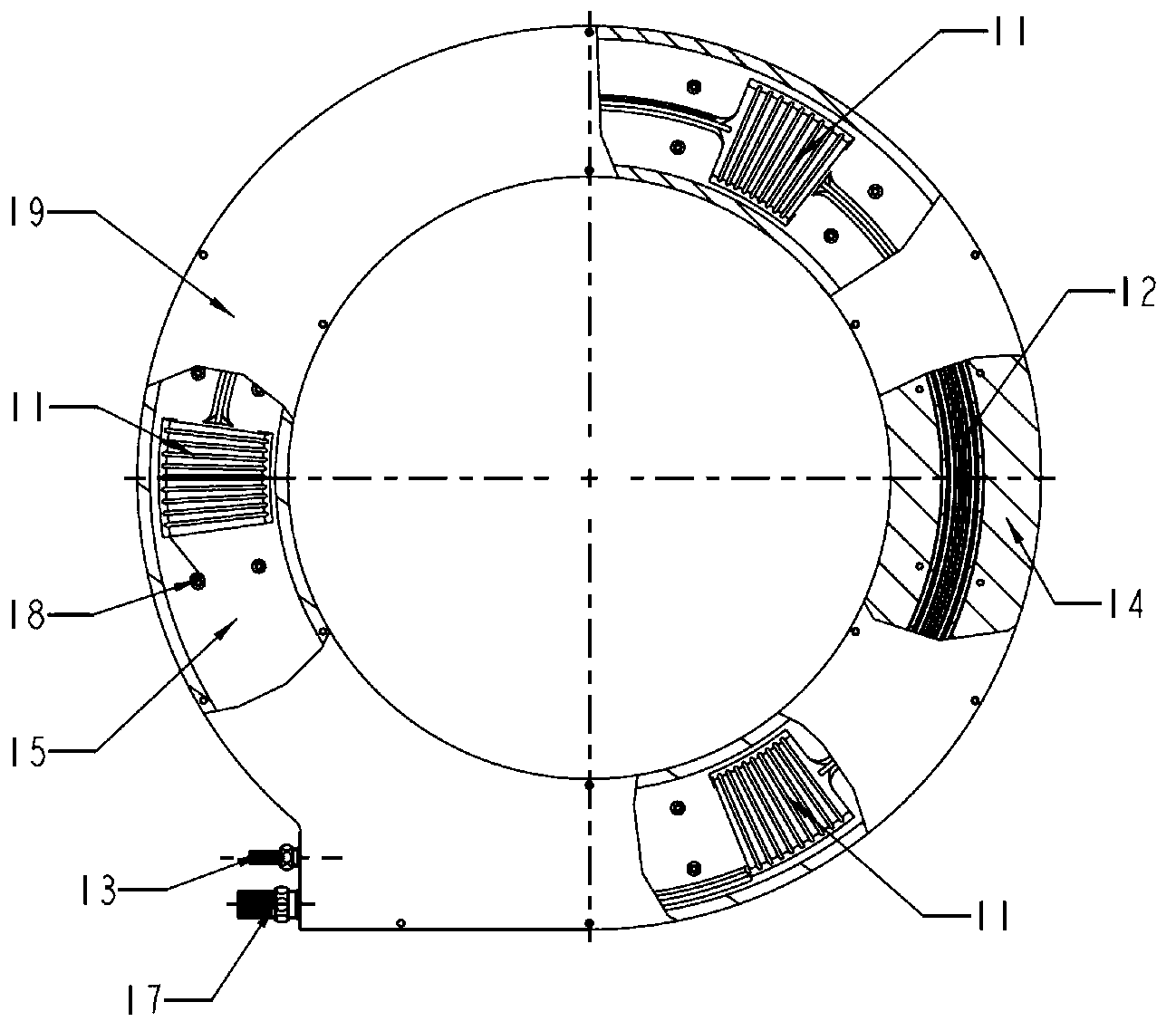

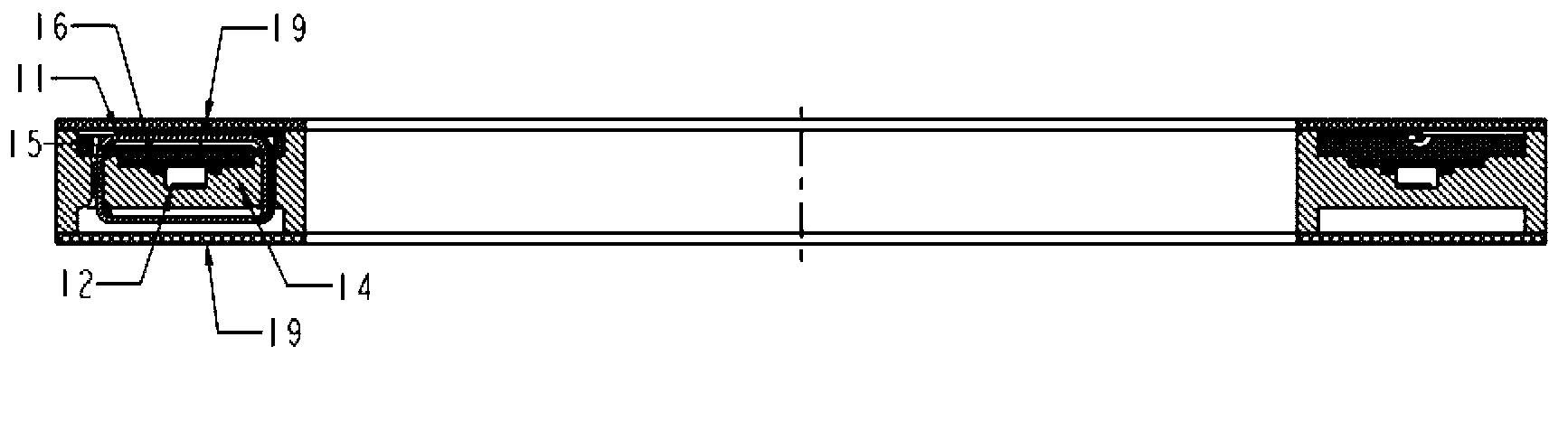

[0028] Such as figure 2 , 3 As shown, the equal-ampere-turn optical fiber sensitive ring 10 includes an equal-ampere-turn cable 11, an optical fiber 12, an optical fiber outlet 13, a sensitive ring body 14, a liner 15, a sealing ring 16, a cable inlet 17, and Cable blind section grounding screw 18, insulating cover 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com