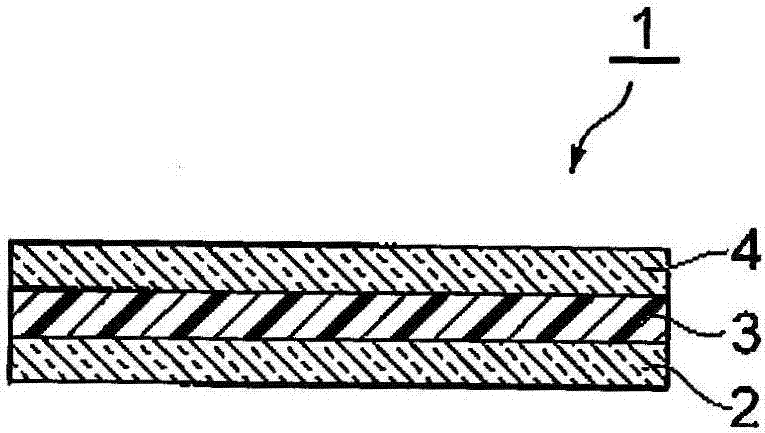

Photosensitive resin composition, photosensitive element, method for forming resist pattern, and method for manufacturing printed circuit board

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, can solve the problems of multi-exposure time, etc., and achieve the effect of excellent resolution and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

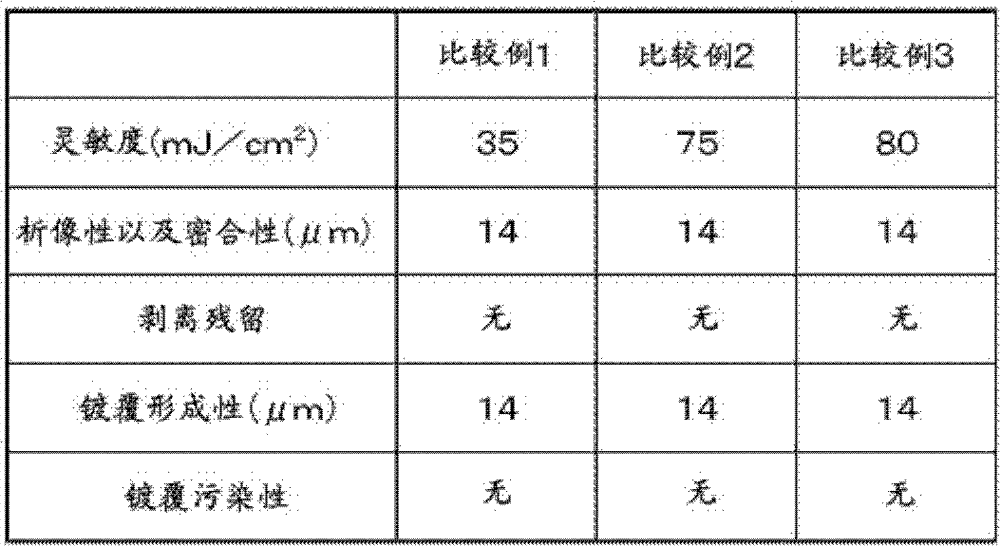

Embodiment 1~10 and comparative example 1~3

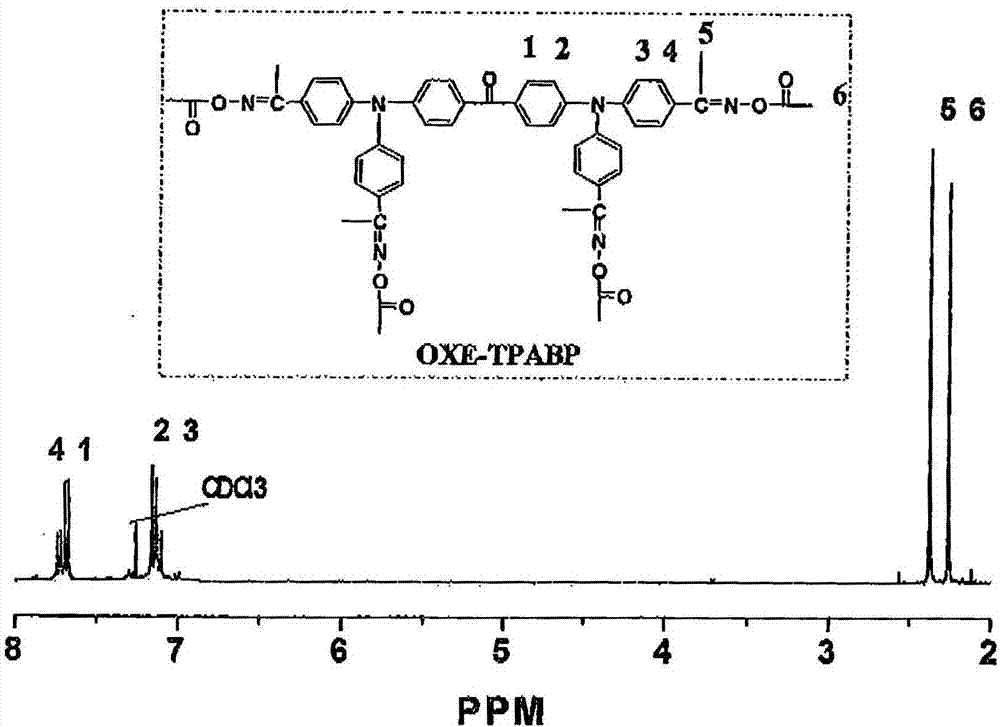

[0136] (Preparation of Solution of Photosensitive Resin Composition)

[0137] The components shown in following Table 1 were mixed in the compounding quantity shown in the table, and the solution of the photosensitive resin composition of Examples 1-10 and Comparative Examples 1-3 was prepared. In addition, the compounding quantity of (A) component shown in Table 1 and Table 2 is the mass (amount of solid content) of a non-volatile matter. The details of each component shown in Tables 1 and 2 below are as follows.

[0138]

[0139] [Synthesis of Binder Polymer (A-1)]

[0140] 150g of methacrylic acid, 125g of benzyl methacrylate, 25g of methyl methacrylate and 200g of styrene (mass ratio 30 / 25 / 5 / 40) and azobisisobutyl The solution obtained by mixing 9.0 g of nitriles was referred to as "solution a".

[0141] The solution obtained by dissolving 1.2 g of azobisisobutyronitrile in 100 g of a mixed liquid (mass ratio 3:2) of 60 g of methyl cellosolve and 40 g of toluene was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com