Light-emitting diode (LED) grid screen

A technology of LED light strips and grids, applied in instruments, identification devices, etc., can solve the problems of increased costs and labor costs, inability to make full use of unit screens, and increased mass load, achieving high disassembly and assembly efficiency and saving manpower The effect of material strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

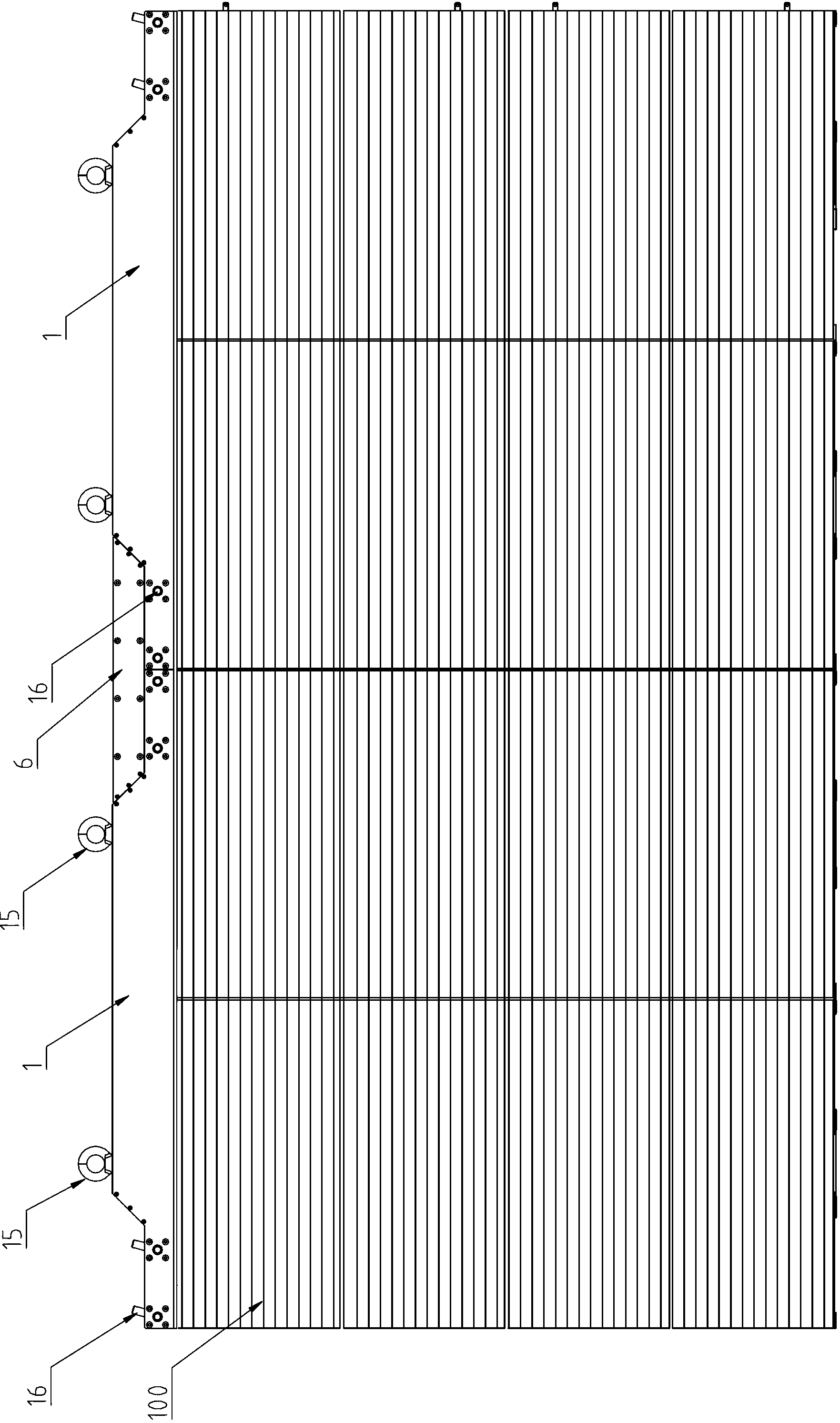

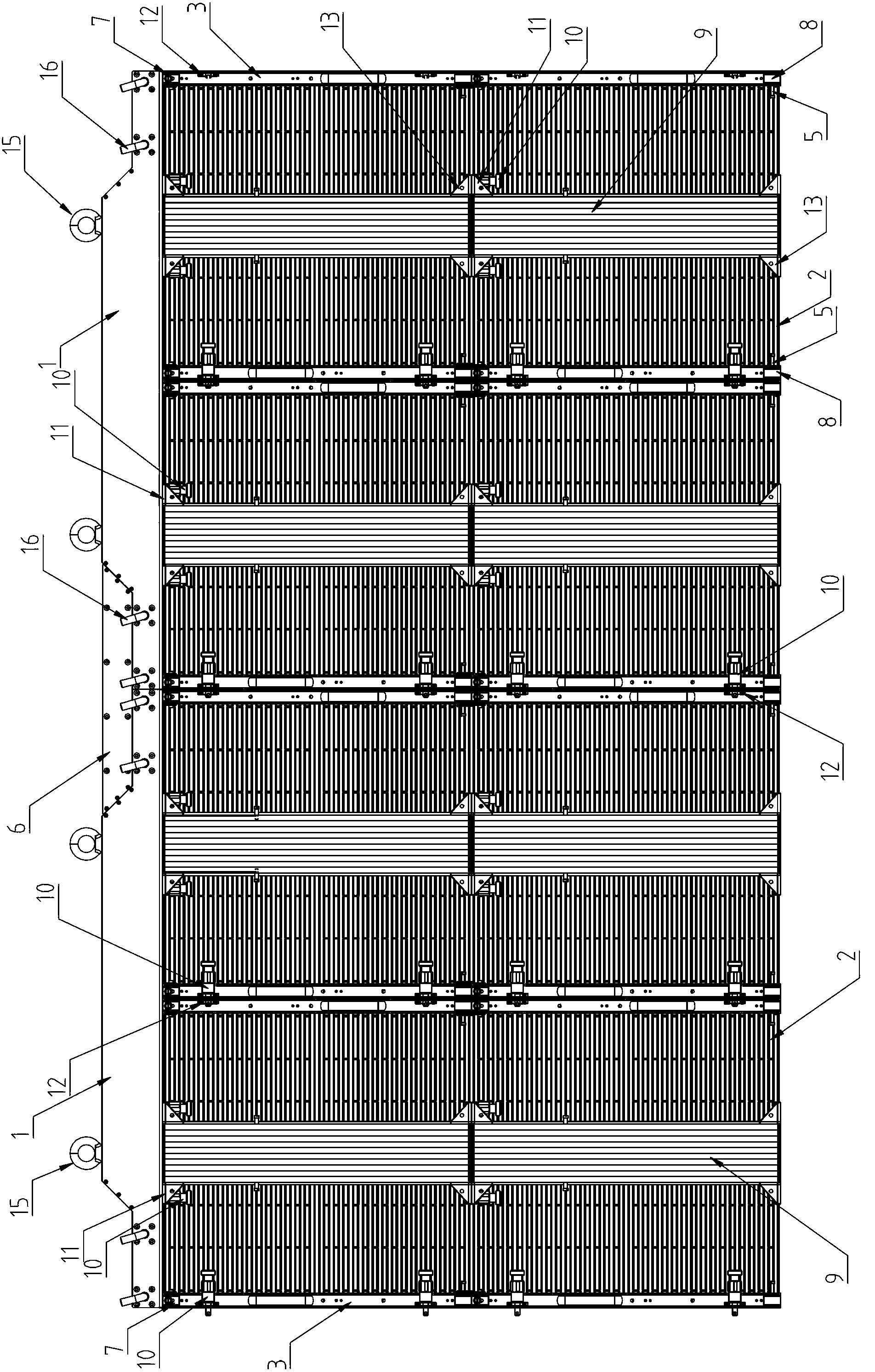

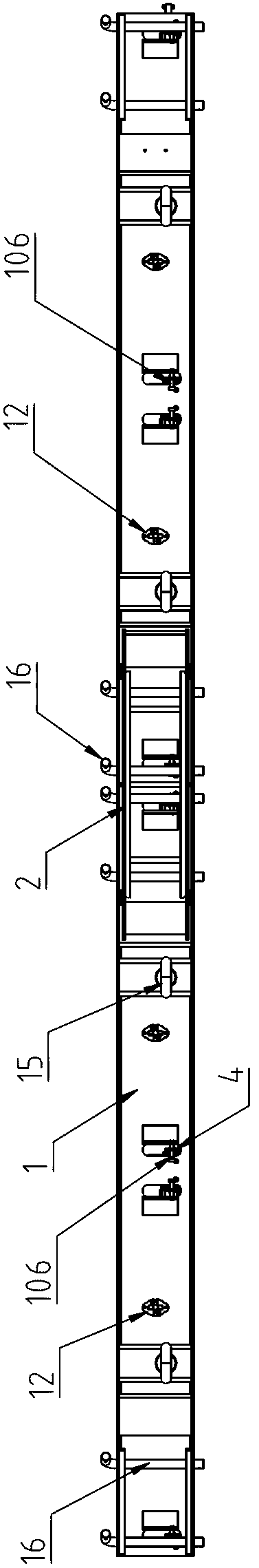

[0051] Such as Figure 1 to Figure 5 As shown, the LED grid screen in the embodiment of the present invention includes hanging beams and multiple unit screens 100 (due to the limitation of the drawing, more unit screens cannot be shown, and this embodiment uses 8 unit screens as an example for illustration).

[0052] The hanging beam includes multiple main beams 1 and multiple connecting beams 6 (due to the limitation of the drawing, it is impossible to show more main beams and connecting beams, this embodiment uses two main beams and one connecting beam as an example to illustrate ), hanging device and unit screen connecting device. The ends of adjacent main beams 1 are connected by connecting beams 6 . The hanging device is fixed on the upper part of the main girder, and the unit screen connecting device is arranged on the lower part of the main girder.

[0053] A plurality of unit screens 100 are combined into a large screen and suspended under the suspension beam through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com