Preparation method for carbon fiber annular cathode

A ring-shaped cathode and carbon fiber technology, which is applied in the manufacture of cold cathodes, electrode systems, and discharge tubes/lamps, etc., can solve problems such as the difficulty in preparing carbon fiber ring-shaped cathodes, and achieve good electron emission effects and stable current-voltage waveforms , the effect of fast start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

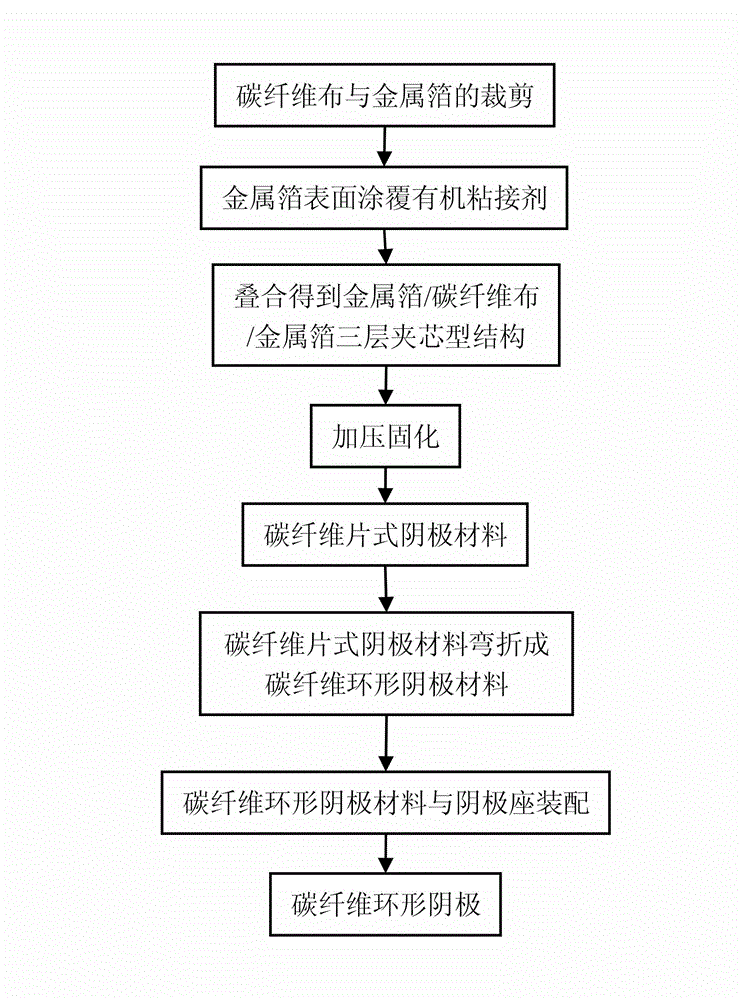

[0032] A kind of preparation method of the carbon fiber annular cathode that outer diameter is 39mm, comprises the following steps:

[0033] 1. Fabrication of carbon fiber sheet cathode material:

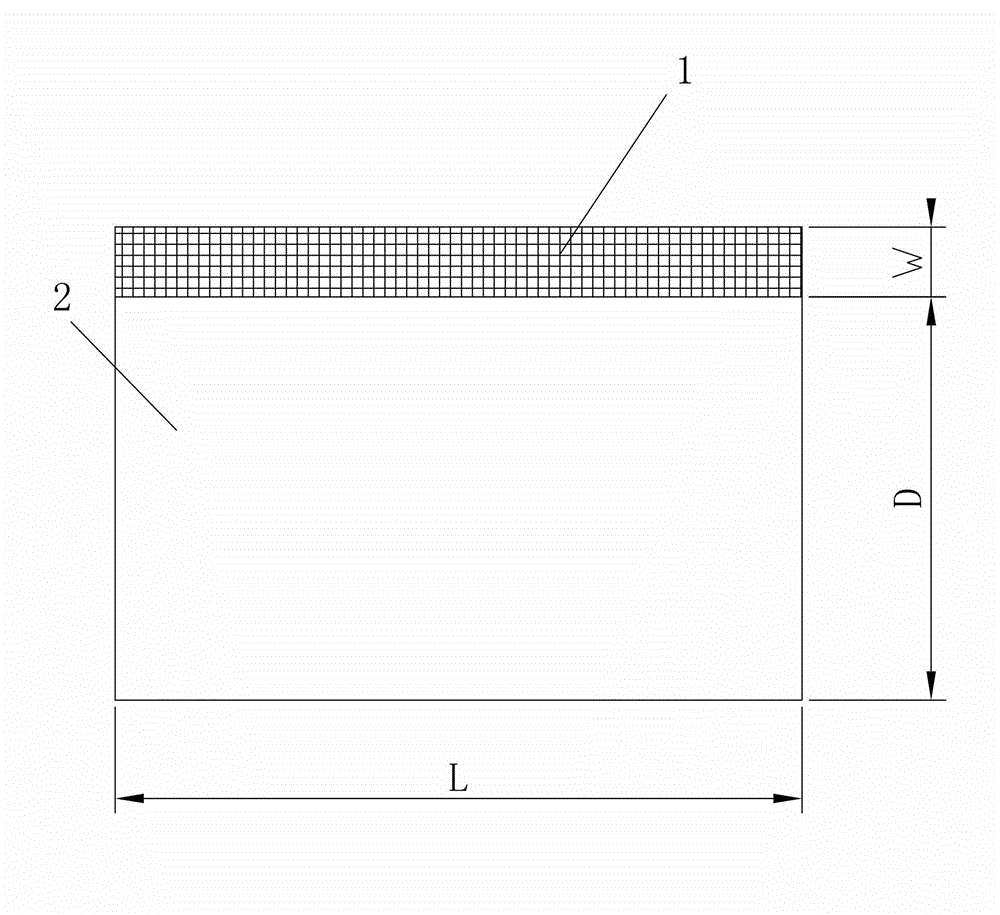

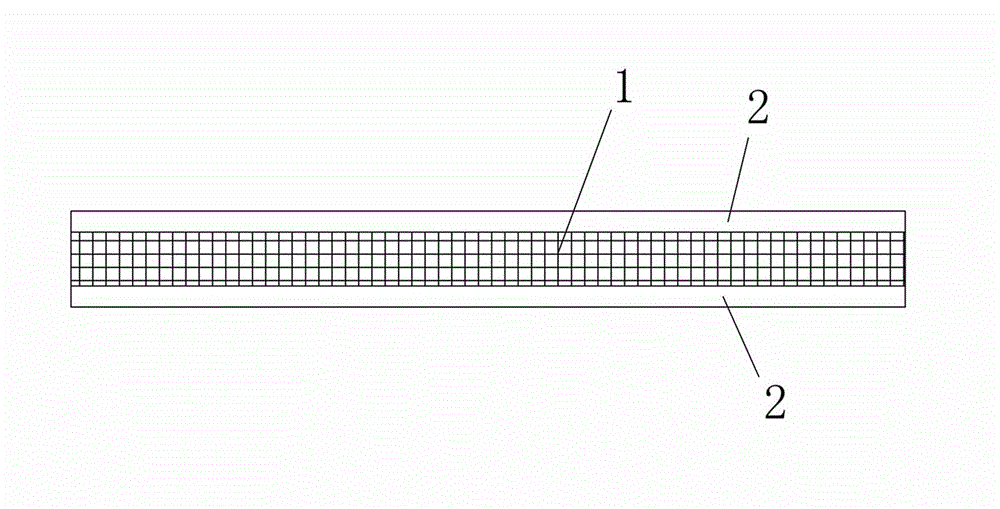

[0034] (1) Prepare a piece of T300 carbon fiber orthogonally woven cloth with a thickness of about 0.2mm, cut it into a rectangular carbon fiber cloth 1 of 122.5mm×12mm along the direction of warp and weft parallel to the carbon fiber orthogonally woven cloth, and then two pieces Copper foils with a thickness of 0.05mm are respectively cut into rectangular copper foils 2 of 122.5mm×10mm;

[0035] (2) Coat the surfaces of two rectangular copper foils 2 with epoxy resin adhesive, each copper foil 2 is only coated on one surface, and the rectangular carbon fiber cloth 1 and two copper foils 2 are combined to form a copper foil 2 / carbon fiber Three-layer composite sandwich structure of cloth 1 / copper foil 2, two pieces of copper foil 2 are located on the outside, sandwiching carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com