Manufacturing method of back-contacted solar cell bunches

A kind of solar cell, technology of making method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0025] The difference in the shape of the battery electrodes and the difference in the width of the welding strip is only to illustrate the process steps of this patent, and does not mean that there is a difference in the actual shape and width. This patent is applicable to P-type back-contact solar cells and N-type back-contact solar cells, and the specific embodiments only use P-type back-contact solar cells as an example to illustrate the patent of the invention.

[0026] The present invention specifically comprises the following steps:

[0027] Step (a):

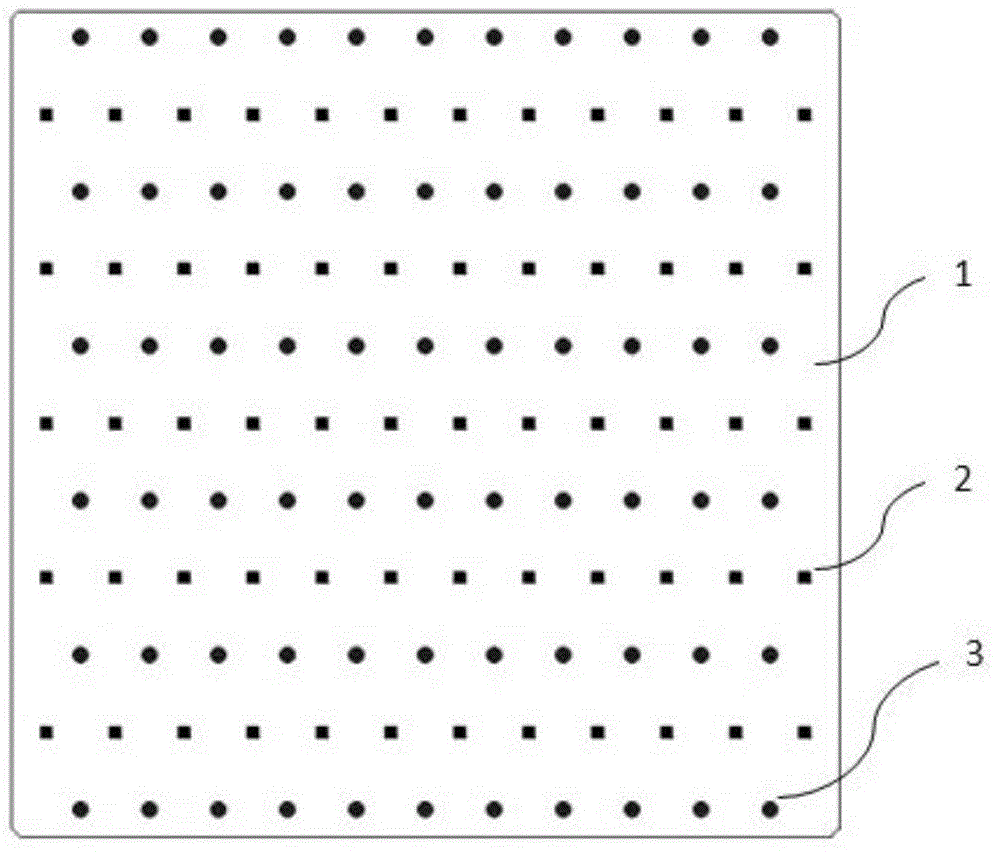

[0028] see figure 1 , printing soldering solder on the positive electrode 2 and the negative electrode 3 of the battery sheet 1 at the same time, and the printing thickness of the solder i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap