High speed switch reluctance motor rotor with soft magnetic materials

A soft magnetic material and high-speed switch technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of limited application range, torque ripple, and lack of bidirectional self-starting ability, etc., to achieve improved Lower limit value, small eddy current effect, and extended current conduction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

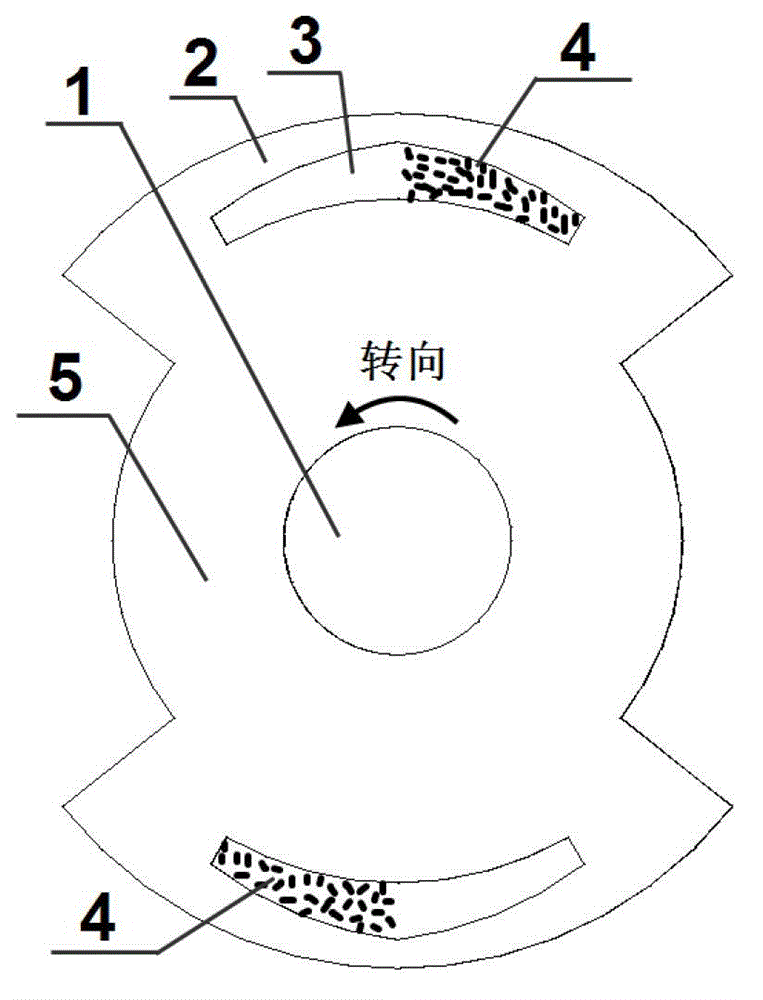

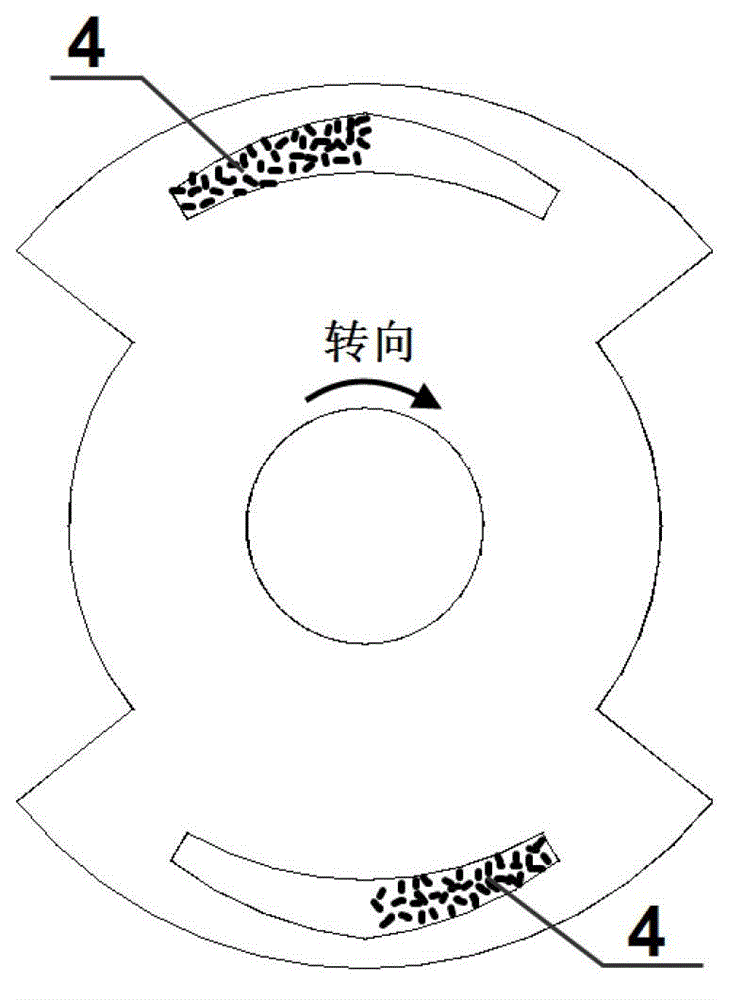

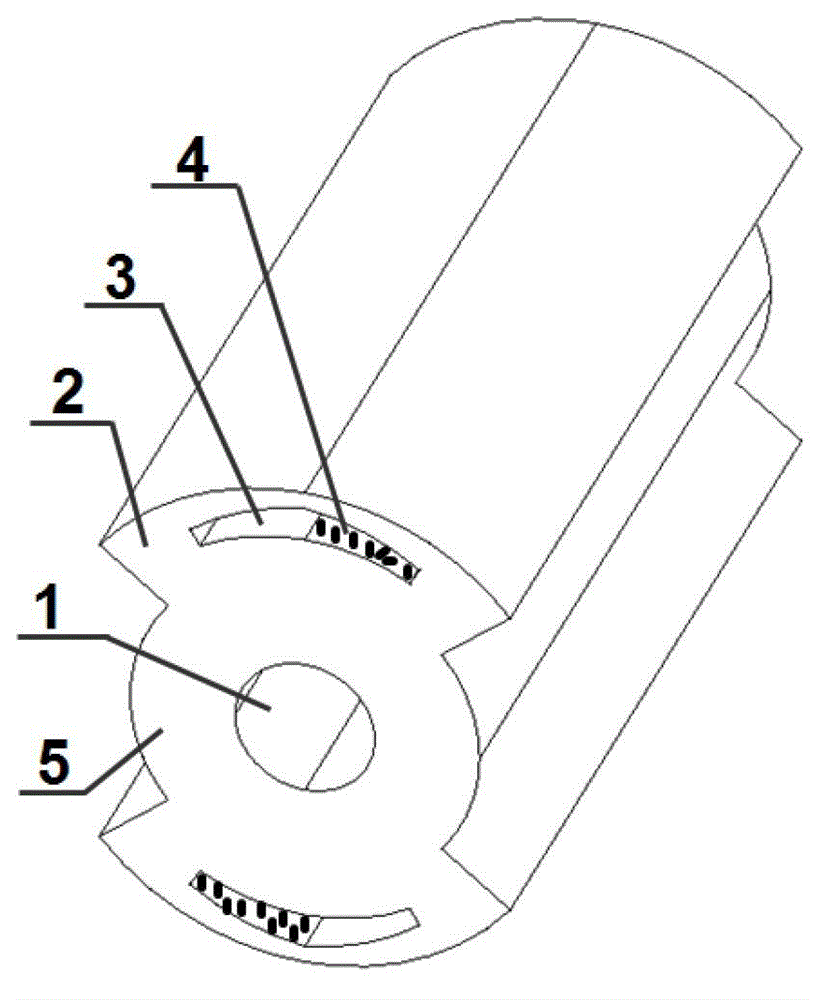

[0029] see figure 1 , figure 2 and image 3 , a high-speed switched reluctance motor rotor with soft magnetic materials, including a shaft 1, a rotor salient pole 2 and a rotor yoke 5, a salient pole groove 3 is set on each of the two rotor salient poles 2, and two salient pole concave poles The groove 3 is symmetrical (symmetrical to the axis 1 ), the salient pole groove 3 is composed of two symmetrical grooves, and the soft magnetic material 4 of 40-50% of its volume is arranged in the salient pole groove 3 .

[0030] In this way, when the rotor runs at high speed, the centrifugal force is used to keep the soft magnetic material in a groove of the salient pole groove 3; when the motor rotates in reverse, the soft magnetic material changes position with the direction of the centrifugal fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com