Air cleaning machine

An air cleaning and air technology, applied in the direction of gasification material, using liquid separating agent, dispersing particle separation, etc., can solve the problems of secondary pollution, reducing purification effect, emission of harmful substances, etc., to achieve convenient replacement and enhanced purification effect , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

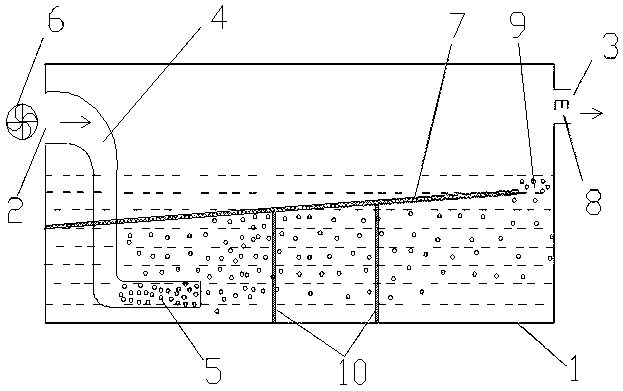

[0021] Such as figure 1 As shown, the air cleaning machine of the present invention includes a tank body 1 for holding water, and the left and right side walls of the upper part of the tank body 1 are respectively provided with an air inlet 2 and an air outlet port 3, and the tank body 1 is provided with an end connected to the air inlet Port 2, one end extends to the pipe 4 at the bottom of the tank body 1, the pipe 4 is "L" shaped under the water surface, that is, there is a section of pipe horizontal to the bottom of the tank body 1, and the pipe 4 is located at one end of the bottom of the tank body 1. The mouth is closed, the pipe wall has micropores 5, and the air inlet 2 is provided with a blower 6. The air blown into the pipeline 4 by the air blower 6 is pressed into the water from the micropore 5 and can be broken into tiny bubbles.

[0022] In order to make the tiny air bubbles formed by the micropores on the pipeline move in the water for a certain distance before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com