Grading hydrophobic and condensed water sensible heat cascade using relaxation heat setting machine

A technology of heat setting machine and condensed water, which is applied in the direction of dryers, lighting and heating equipment, textiles and papermaking, etc. It can solve the problems of deteriorating heat exchange efficiency, failure to maintain pressure difference, and large waste heat loss, etc., and achieve reduction The effect of steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

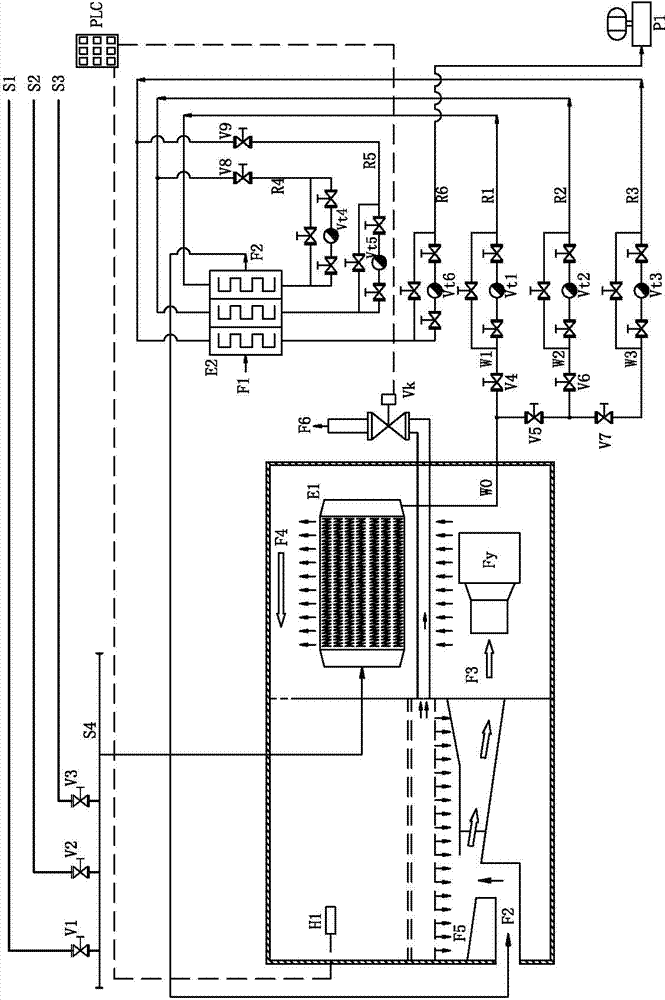

[0014] Such as figure 1 As shown, the present invention uses a relaxation heat setting machine for grading hydrophobic and condensed water sensible heat steps. The inner chamber of the relaxation heat setting machine is provided with a fan Fy, a heat exchanger E1 and a drying chamber for drying the product. The fan Fy The air suction port of the fan Fy is connected with the supplementary air port on the cabinet, the air outlet of the fan Fy is aligned with the heat exchanger E1 above, and the air outlet above the heat exchanger E1 enters the drying chamber, and the air return port and exhaust air are arranged below the drying chamber. The exhaust port leads to the outside of the box through the exhaust pipe, and the return air port also communicates with the suction port of the fan Fy.

[0015] An exhaust control valve Vk controlled by a PLC controller is installed on the exhaust pipe of the relaxation heat setting machine, and a humidity sensor H1 is installed in the drying r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap