Multi-row pile foundation pit support structure and its construction method

A technology for foundation pit support and support structure, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as unsatisfactory, occupying underground space, etc., and achieves the effect of saving construction period, convenient excavation, and no maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

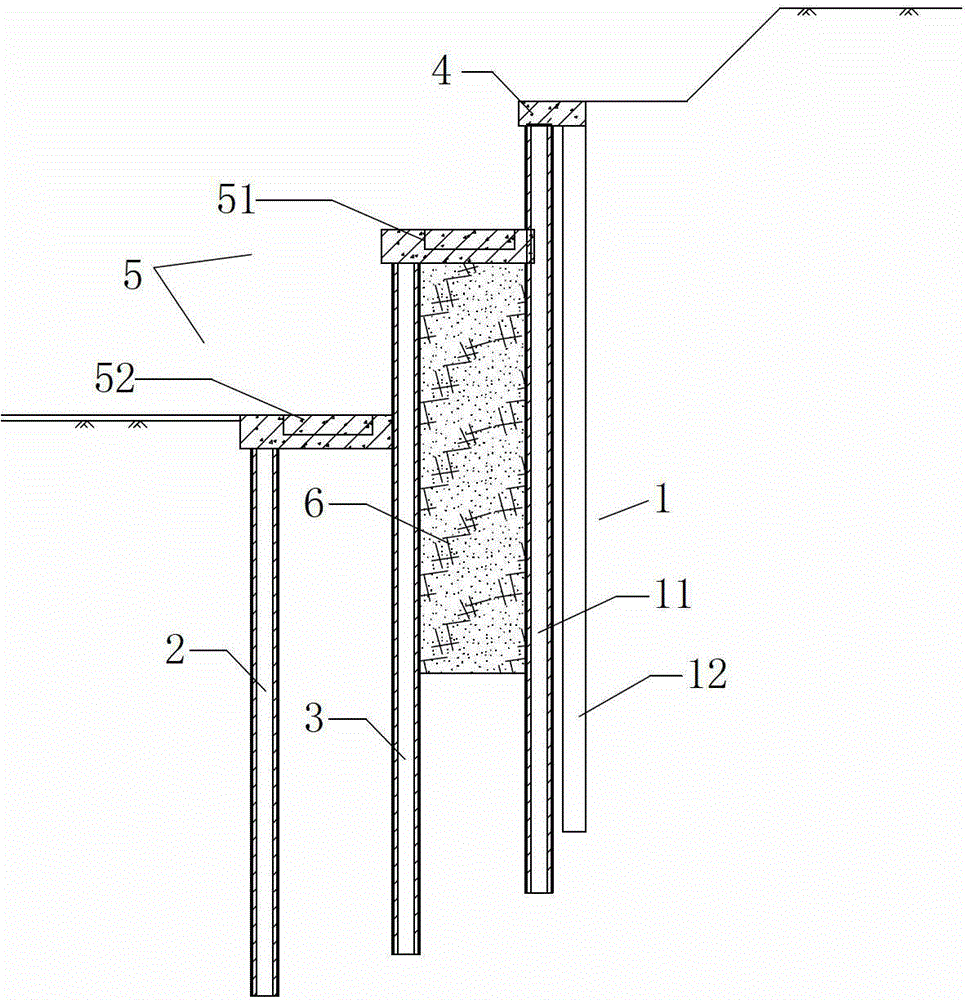

[0029] Embodiment 1 Multi-row pile stepped foundation pit support structure

[0030] Multi-row pile stepped foundation pit support structure (such as figure 1 Shown) The specific implementation method is:

[0031] 1) Construct outer row water stop pile 11, soil retaining pile 12, middle row soil retaining pile 3, and inner row soil retaining pile 2, and repeat the above production until all water stop piles and soil retaining piles are formed;

[0032] 2) Reinforcing soil 6 between construction piles;

[0033] 3) Excavate the earthwork to the top of the outer soil retaining and water-stop pile 1, and construct the pile top ring beam 4;

[0034] 4) Excavate the earthwork to the pile top elevation of the middle row of soil retaining piles 3, and use reinforced concrete construction to connect the beam plate 5 at the pile top of the middle row of soil retaining piles 3 and the corresponding waist of the outer row of soil retaining piles 1;

[0035] 5) Continue to excavate the ...

Embodiment 2

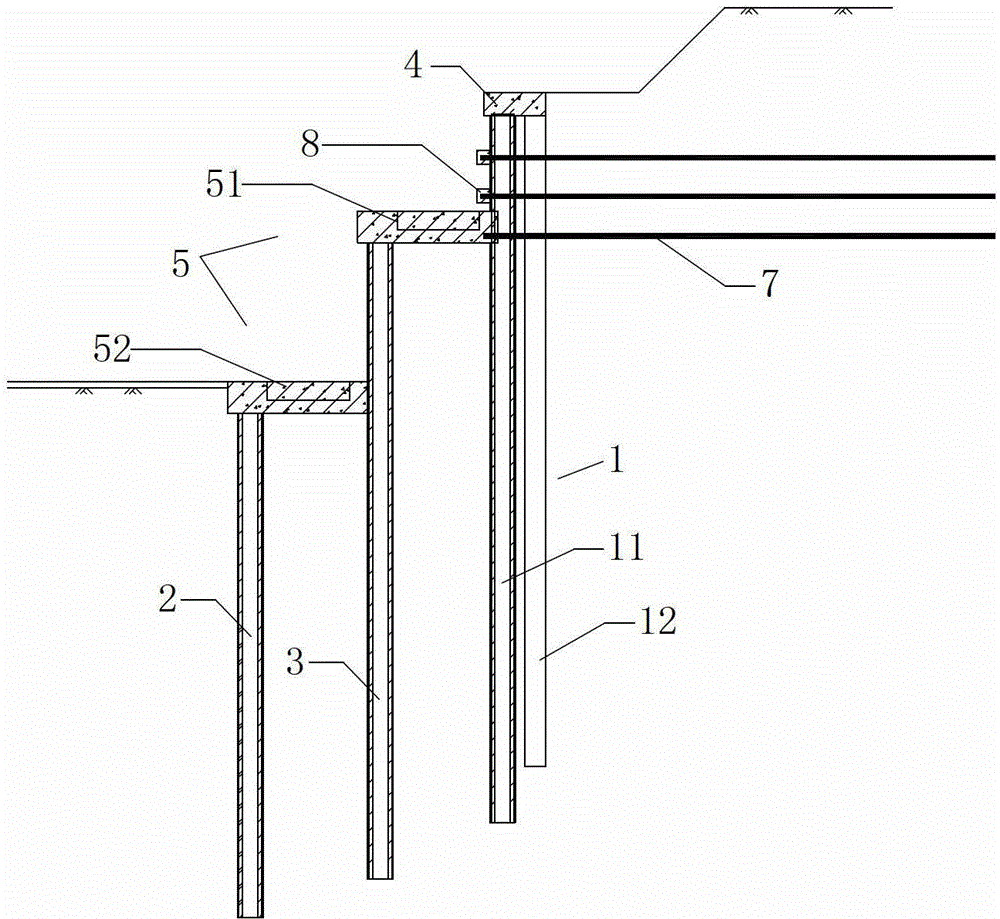

[0037] Embodiment 2 Multi-row pile stepped foundation pit support structure with reinforcement

[0038] In order to further improve the support depth of the foundation pit and expand the application of this method in the weak soil layer, reinforcement 7 can be added on the basis of the above-mentioned embodiment 1 to form a multi-row pile stepped foundation pit support structure with reinforcement ( Such as figure 2 shown), its concrete construction method is basically the same as the construction method of embodiment 1, and the difference is that two procedures are inserted between example 1 procedure 3) and 4), i.e.

[0039] Insertion 1) Continue to excavate the earth to the predetermined elevation of the reinforcement 7 on the first layer, and implant the reinforcement 7 horizontally into the soil behind the outer row of soil retaining and water-stop piles 1 according to the design interval; One end of the outer row soil retaining water stop pile 1 is connected;

[0040]...

Embodiment 3

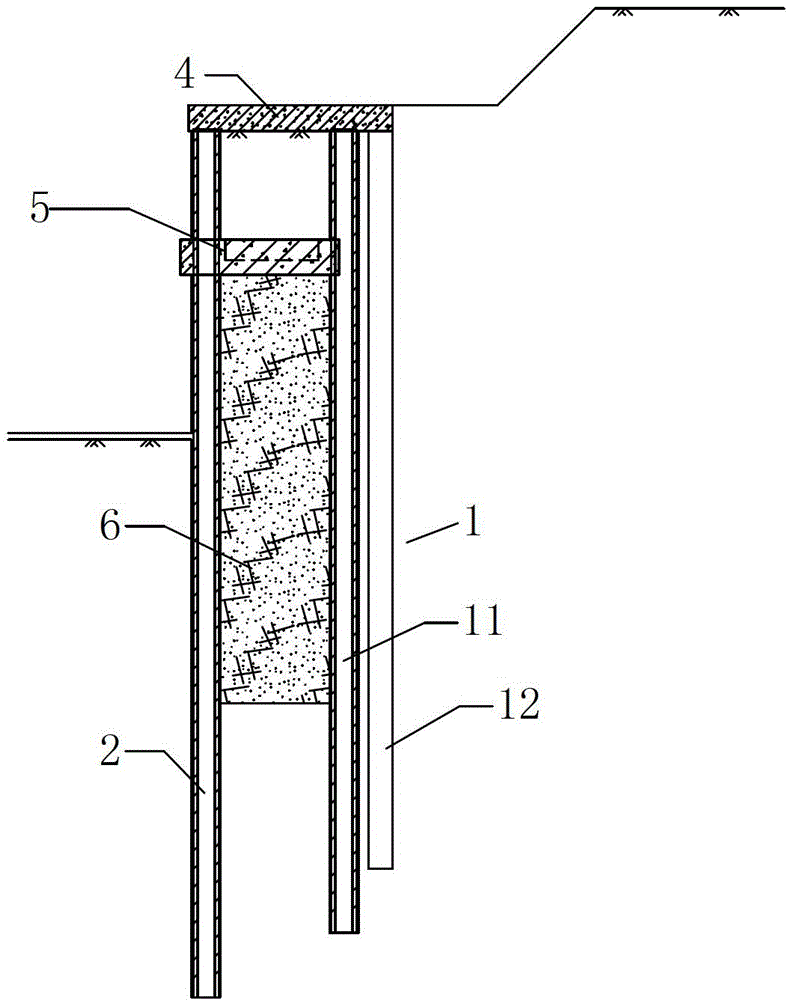

[0042] Embodiment 3 Double-row pile frame type foundation pit support structure

[0043] When there are only two rows of support piles left, and the pile top elevations of the two rows of piles are the same, a double-row pile frame type foundation pit support structure can be formed (such as image 3 shown), the specific construction method is as follows:

[0044] 1) Construction of outer row water stop pile 11, soil retaining pile 12, and inner row soil retaining pile 2. The water-stop pile 11 can be a stirring pile and a rotary grouting pile, and the soil-retaining pile can be a bored pile, a prestressed pipe pile, and an H-shaped steel. Repeat the above manufacturing until all the water-stop piles and soil-retaining piles are formed;

[0045] 2) Reinforcing soil 6 between construction piles;

[0046] 3) Excavate the earthwork to the top of the outer row of soil retaining piles 1 and the inner row of soil retaining piles 2, and add temporary support on the top of the two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com