Pressure balancing device

A technology of balancing device and pressure, which is applied in wellbore/well components, sealing/package, earthwork drilling and production, etc. It can solve the problems of difficulty in ensuring the reliability of high-solid particles, high requirements for sealing pairs, and large space occupation. Achieve the effects of obvious righting effect, normal operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

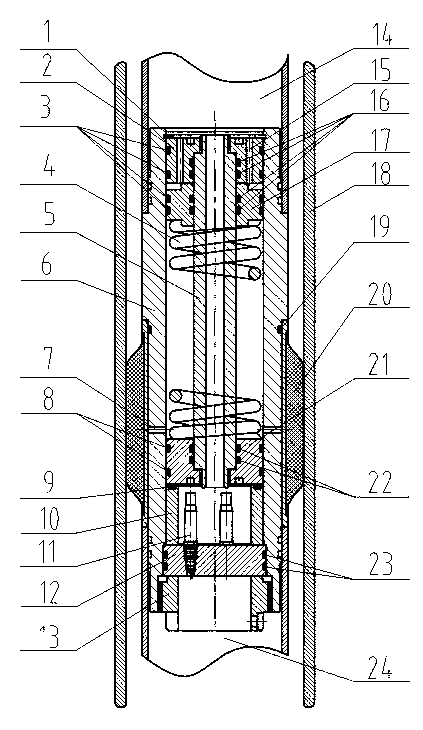

[0016] Embodiment 2 is an optimization scheme based on Embodiment 1. Among them: the upper end of the annular cavity of the wiring pipe 5 and the joint 6 is blocked by the oil plug 2. After the inner and outer walls are respectively matched with the wiring pipe 5 and the joint 6 through the sealing rings (16, 3), the limit retaining ring 1 Lock fit with the built-in annular groove of the connector. The lower end of the annular cavity between the wiring pipe 5 and the joint 6 is sealed with a plug 21. The inner and outer walls are respectively matched with the wiring pipe 5 and the joint 6 through the sealing rings (22, 8), and then the axial gap adjustment pad 9, the limit The ring 10 and the line plug 12 are fixedly connected and locked by the plug pressing cap 13 and the built-in screw of the joint. The inner and outer walls of the floating piston 17 form sliding and sealing cooperation with the cable conduit 5 and the joint 6 through the sealing rings (16, 3) respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com