Quick inflator

A pumping pump, fast technology, applied in the direction of liquid variable volume machinery, variable volume pump components, machines/engines, etc., can solve the problems of small displacement, low work efficiency, slow pumping speed, etc. The effect of large, high work efficiency and fast boosting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

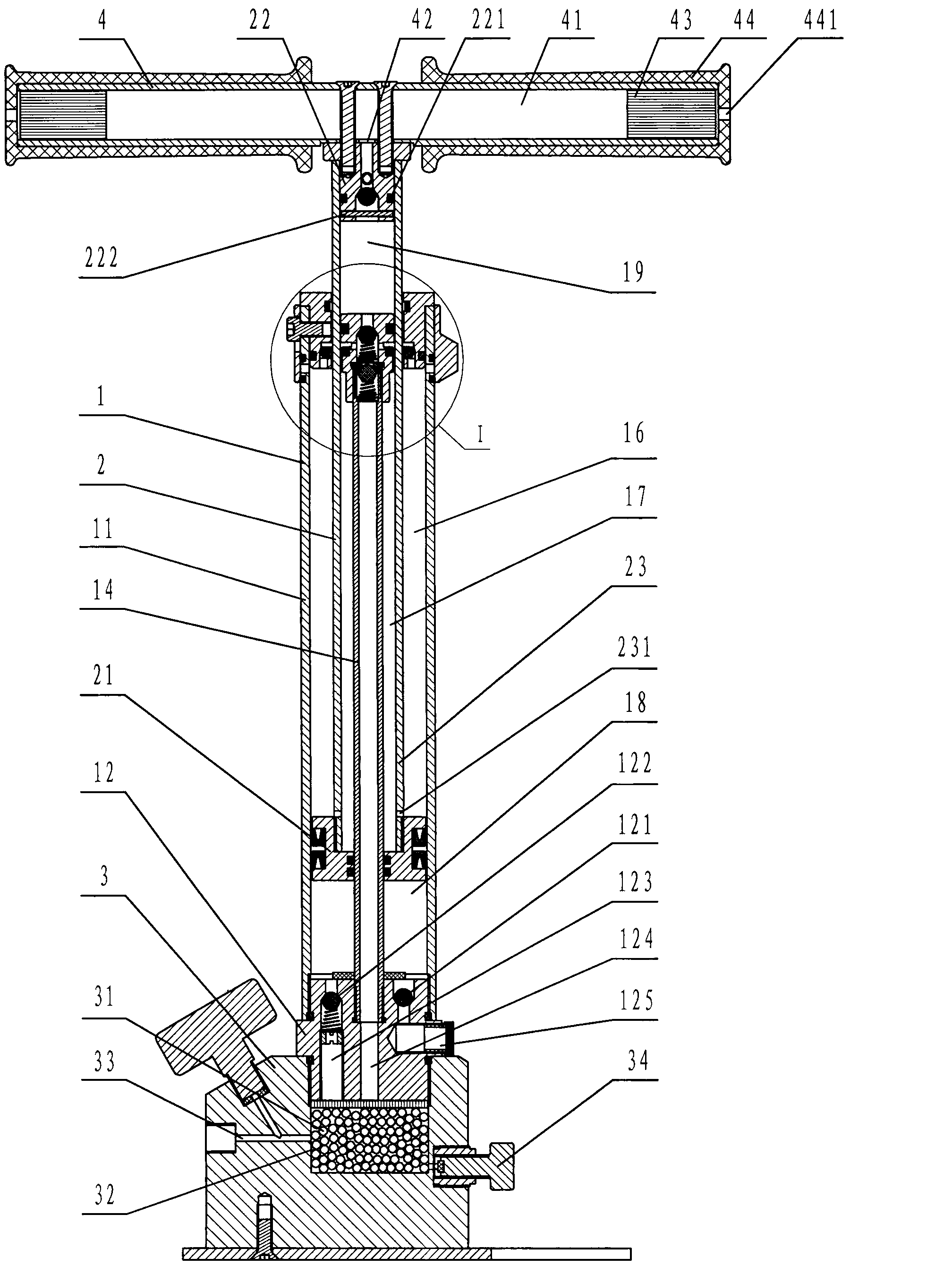

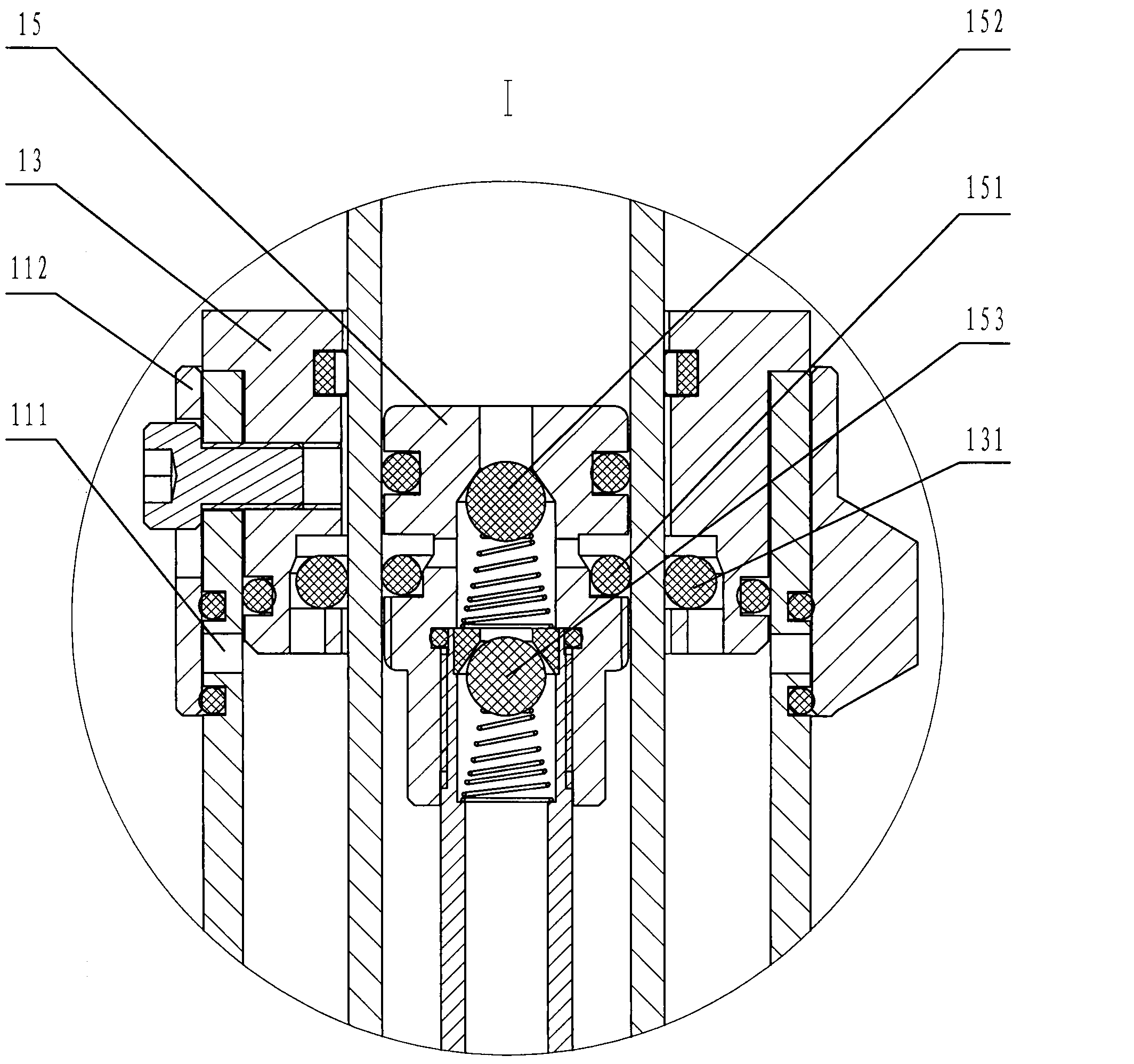

[0016] Such as figure 1 and figure 2 Shown: a quick pump, which is composed of a pump 1, a piston 2, a base 3 and a handle 4. The gas cylinder 1 is composed of a cylinder body 11 , a cylinder bottom 12 , a cylinder cover 13 , an air guide tube 14 and a valve seat 15 . The air guide tube 14 is located at the center of the cylinder body 11, the lower end is fixed on the cylinder bottom 12, and the upper end is connected with a fixed valve seat 15; the piston 2 is composed of a piston one 21, a piston two 22 and a hollow piston rod 23 with a through hole 231 at the lower end. composition. The hollow piston rod 23 is located outside the air duct 14 and the valve seat 15, the lower end is connected with the fixed piston 1 21, and the upper end is connected with the fixed piston 2 22; The outer wall forms the air chamber 2 17, the piston 1 21 and the cylinder bottom 12 form the air chamber 3 18, the piston 22 and the valve seat 15 form the air chamber 4 19; the base 3 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com