Roller type bidirectional overrunning clutch

An overrunning clutch and roller technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problems of lowering the control accuracy of the claw, increasing the complexity of the structure, and reducing the diameter, and achieves a simple movement mode and extended use. The effect of longevity and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

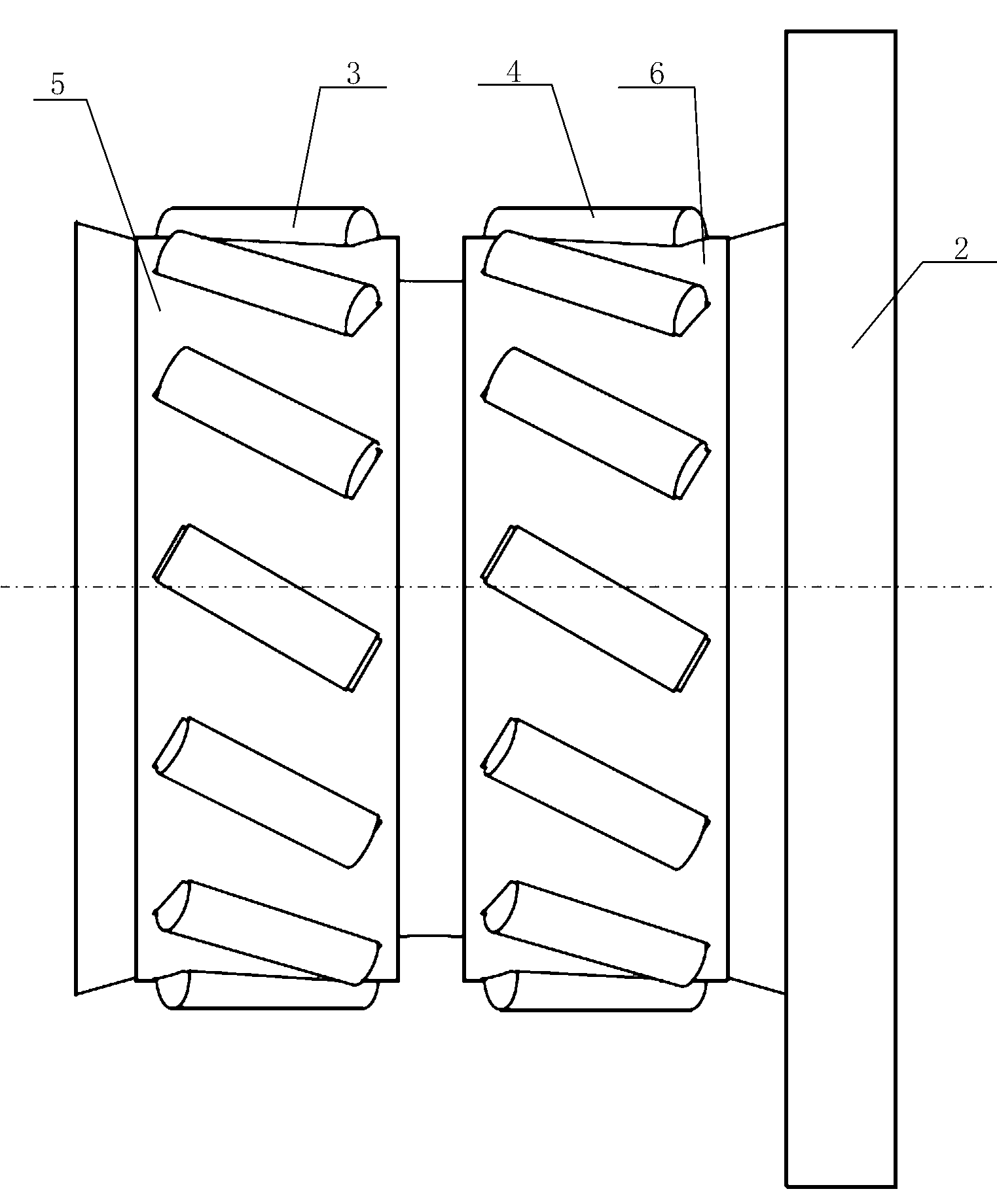

[0023] The present invention is a kind of roller type two-way overrunning clutch, and the roller type two-way overrunning clutch can transmit the rated torque of different sizes, such as rated torque=650N. More first rollers and second rollers can be installed in space, and the ability to transmit torque is better than ordinary roller type two-way overrunning clutches.

[0024] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

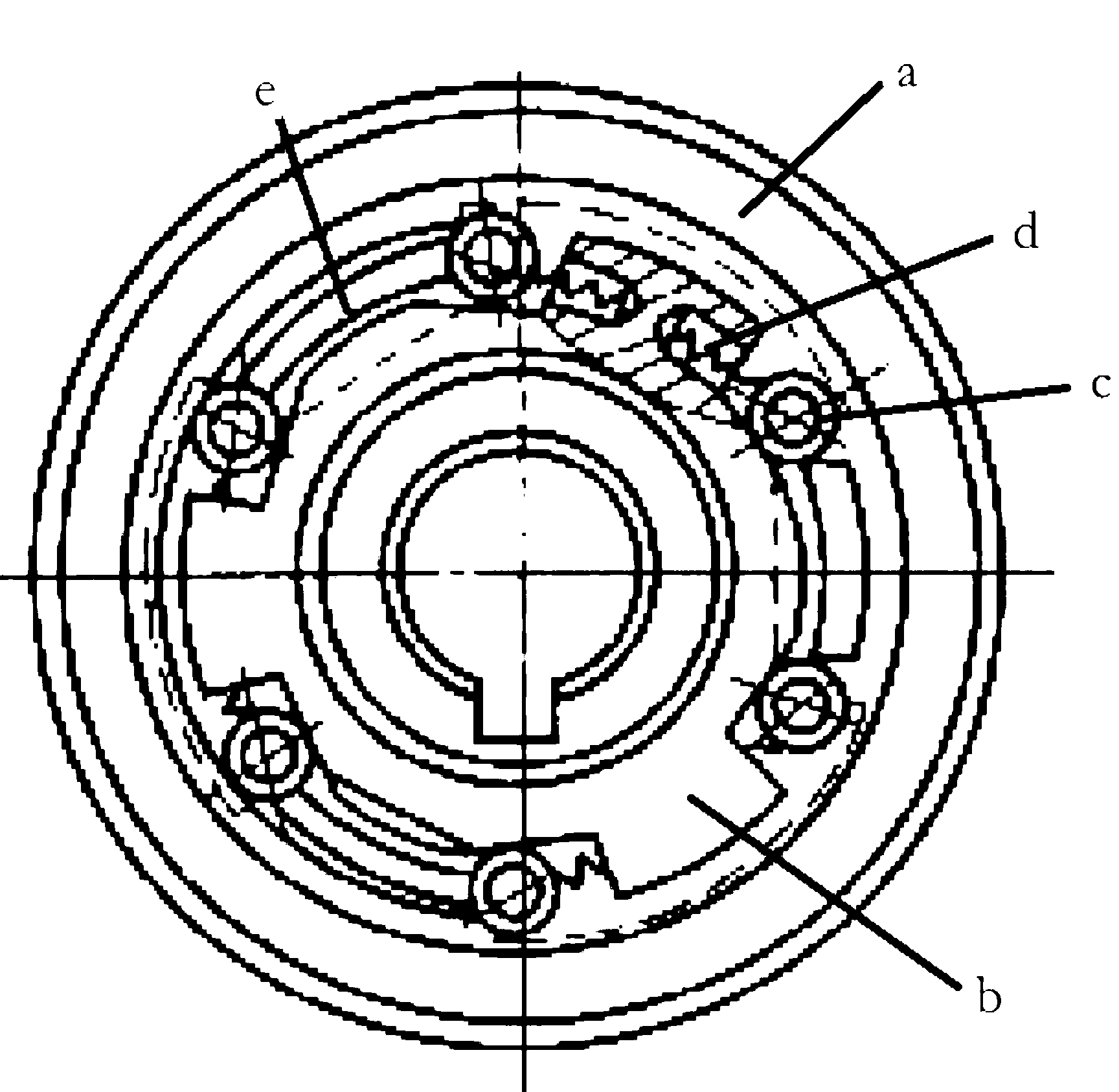

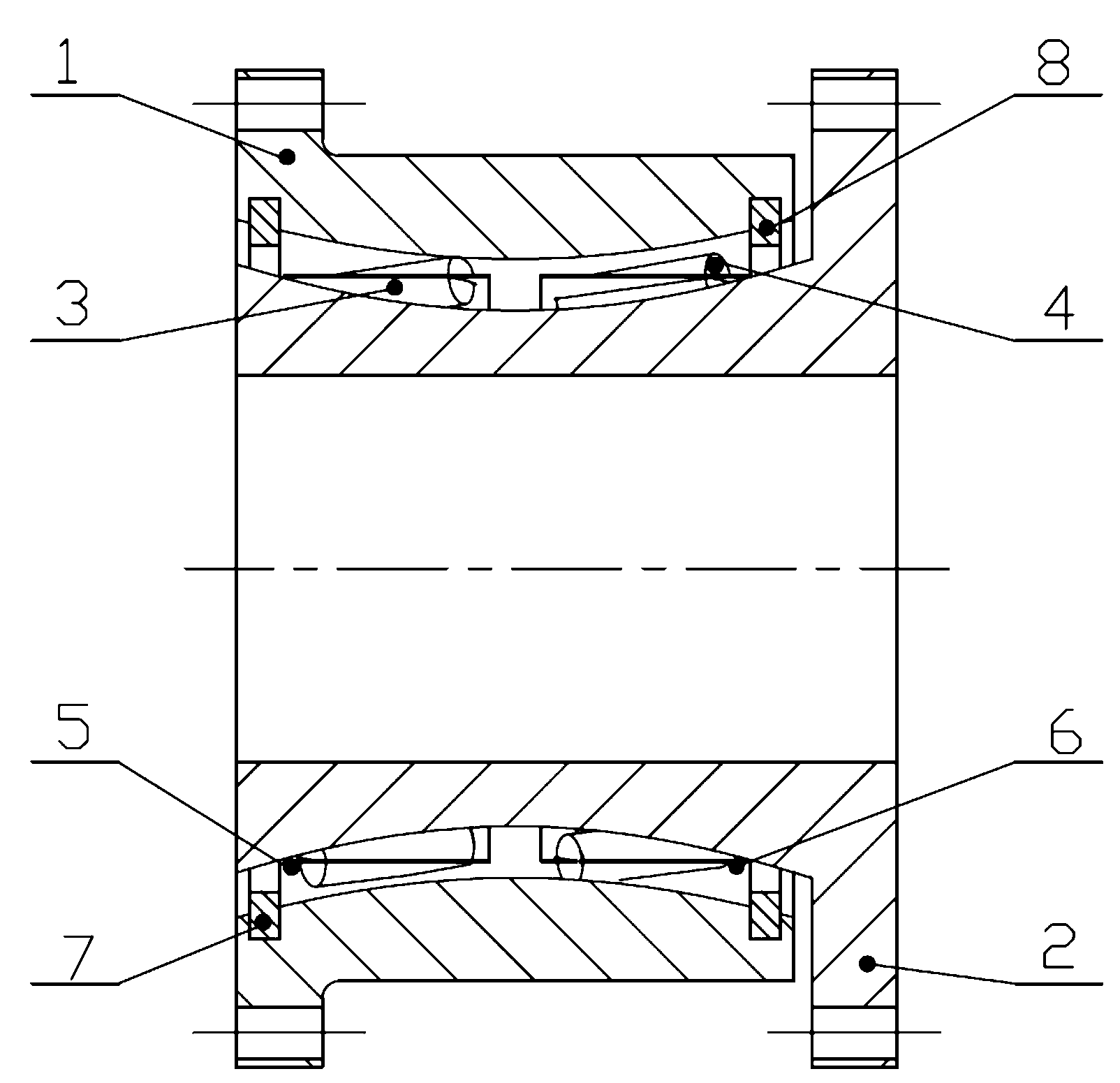

[0025] combine figure 2 , the present invention includes an outer ring 1, an inner ring 2, a first roller 3, a second roller 4, a first corrugated belt 5, a second corrugated belt 6, a retaining ring 7 for a first hole and a retaining ring for a second hole 8. The outer diameter φ6mm and length 20mm of the first roller 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com