Method for forming biomass fuel by comprehensively utilizing straws

A biomass fuel and biomass technology, applied in combustion methods, solid fuel combustion, fuel supply, etc., can solve the problems of smog affecting traffic safety, low utilization efficiency, and environmental pollution, so as to increase residence time and improve utilization efficiency , the effect of wide distribution area

Active Publication Date: 2013-05-01

JIAXING NEW JIES THERMAL POWER

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, most of the biomass energy in my country is mainly utilized by direct combustion, and the total utilization efficiency is lower than 10%, resulting in a huge waste of resources.

With the improvement of farmers' living standards and the advancement of new rural construction, farmers are gradually using liq

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

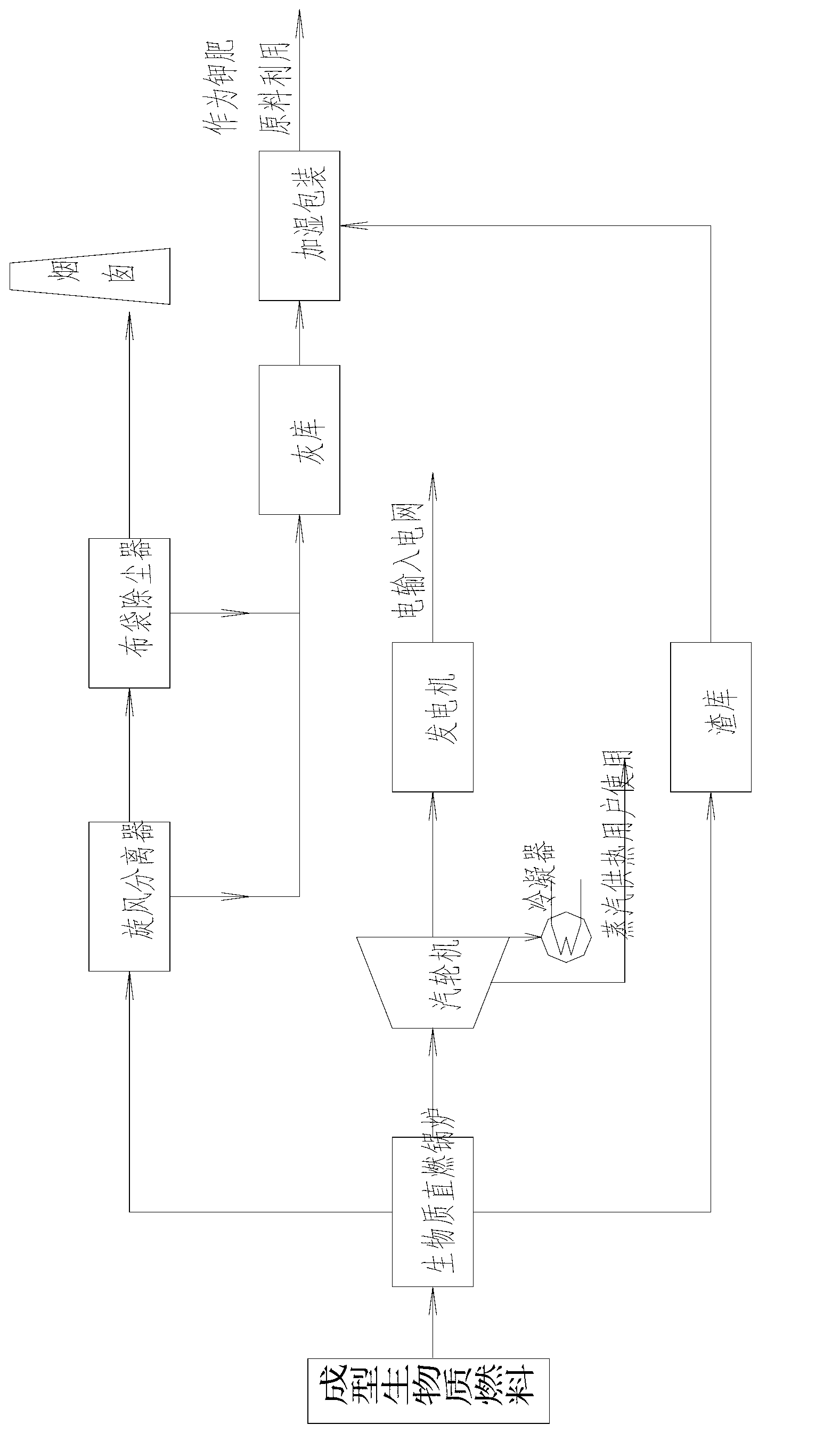

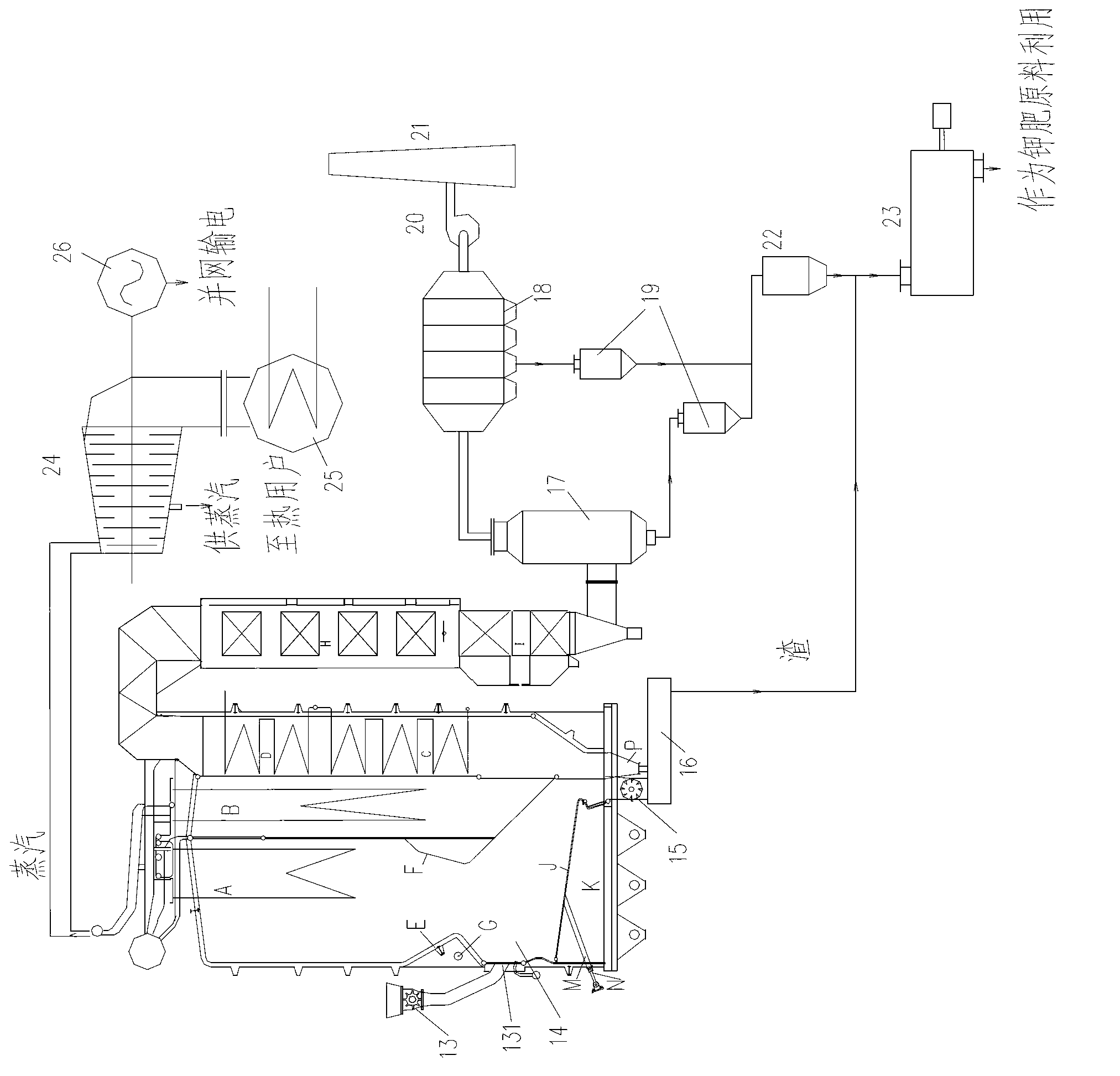

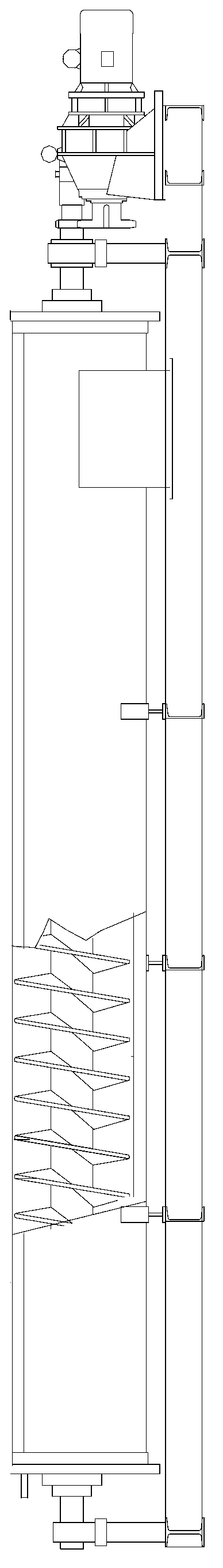

The invention relates to a method for forming biomass fuel by comprehensively utilizing straws. Formed biomass fuel which is formed and produced by pulverizing and squeezing the straws is thrown into a biomass direct-burning boiler, slag and ash obtained through the combustion of the formed biomass fuel are used as potash fertilizer fuel after being processed by a humidifying stirring packing machine, partial steam generated by the boiler is used for generating the power through a steam turbine and a generator, the generated electric power is inputted to an electric network, part of the low-grade steam obtained after the work of the steam turbine is pumped for supplying the heat, and the rest steam is condensed into water by a condenser to be used for the boiler after the working of the steam turbine. The biomass direct-burning boiler utilizes a water-cooling vibration grate boiler structure, the fuel applicability is strong, the straws can be fed into the boiler after being simply pretreated, nearly no abrasion exists, and effects of comprehensive utilization, high efficiency, low cost and cleanliness can be realized by improving the boiler structure.

Description

technical field [0001] The invention relates to a method for comprehensively utilizing straw to form biomass fuel. Background technique [0002] Biomass energy is the solar energy fixed on the earth by the photosynthesis of plants, which is a typical renewable energy source. The use of biomass energy to replace fuels such as oil, coal, and natural gas to produce electricity can reduce dependence on fossil energy, protect national energy resources, and reduce environmental pollution caused by energy consumption. [0003] my country SO 2 The emission space is limited, the country burns more than 700 million tons of coal every year, SO 2 emissions have reached the upper limit. Thanks to SO 2 pollution, acid rain has harmed 30% of the country's land area. In 2003, only acid rain harm caused the loss of agricultural and forestry crops as high as 22 billion yuan, SO 2 The pollution is even more dangerous to people's health. Since the sulfur content in biomass is only about ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23B10/02F23B30/02F22B31/08F22G7/00F23K3/08F23M5/06

Inventor 俞保云孟志浩章平衡计荣林庄建发胡宁吴斌

Owner JIAXING NEW JIES THERMAL POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com