Surface shape detection method for high-reflectivity concave-surface conical reflecting mirror

A high reflectivity, surface shape detection technology, applied in the field of optical detection, can solve problems such as affecting the measurement results, damage to the measurement piece, etc., to achieve the effect of simple operation and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment, but should not limit protection scope of the present invention with this.

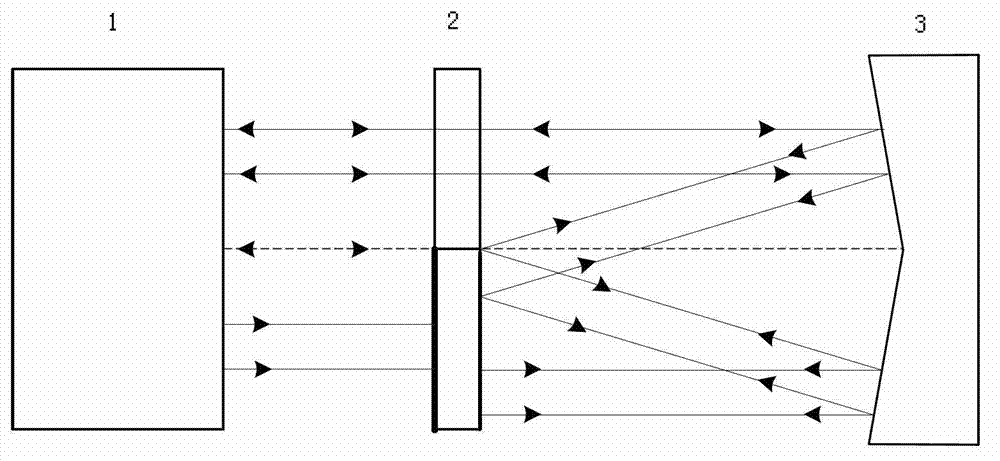

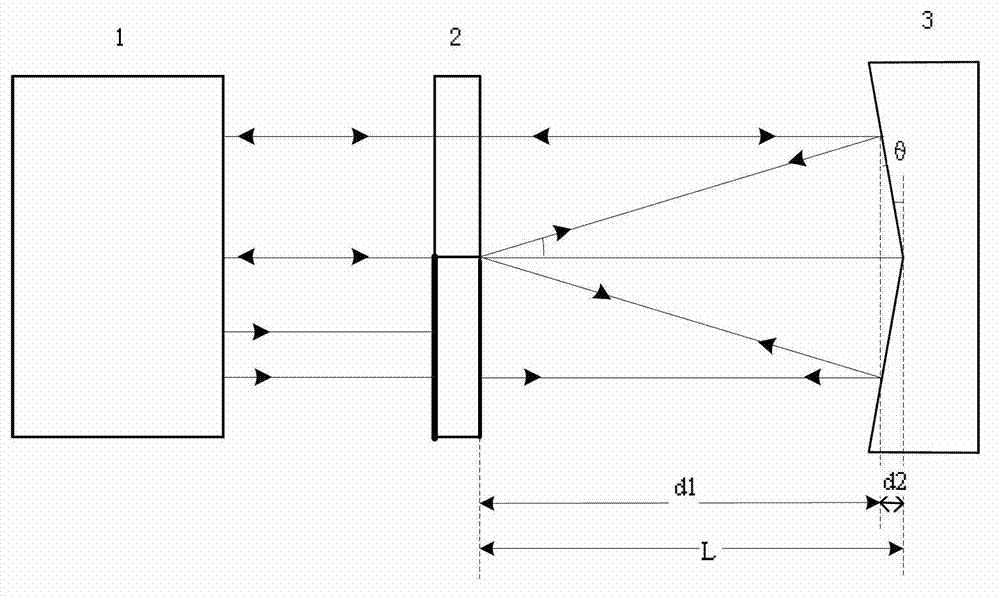

[0023] see first figure 1 , figure 1 It is a principle diagram of the method for detecting the surface shape of the high-reflectivity concave conical mirror of the present invention. The structure of the embodiment of the present invention is as figure 2 As shown, its specific structure is as follows:

[0024] ① Make a partially transparent flat panel 2: paint the lower half of the front surface of the partially transparent flat panel 2 with black paint so that the light beam incident on it is absorbed; coat the lower half of the rear surface of the partially transparent flat panel 2 with reflective paint membrane;

[0025] ②In the direction of the parallel light beam output by the phase-shifting interferometer 1, the partially light-transmitting flat plate 2 and the concave conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com