Sensor measuring method based on double support vector machines

A dual support vector machine and support vector machine technology, which is applied to instruments, computer parts, characters and pattern recognition, etc., can solve the problems of fitting the inverse characteristics of sensors, measurement errors, etc., and achieves small modeling workload and fast calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

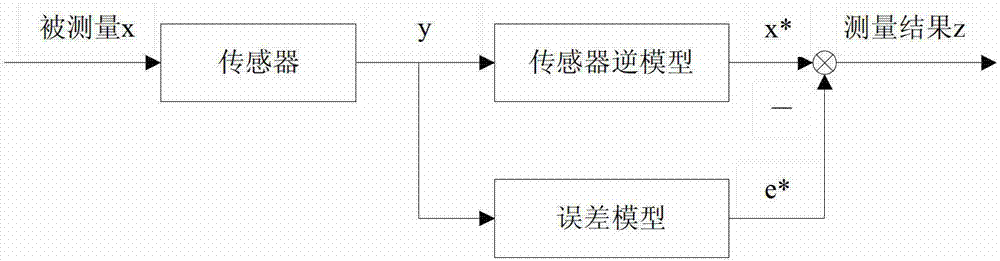

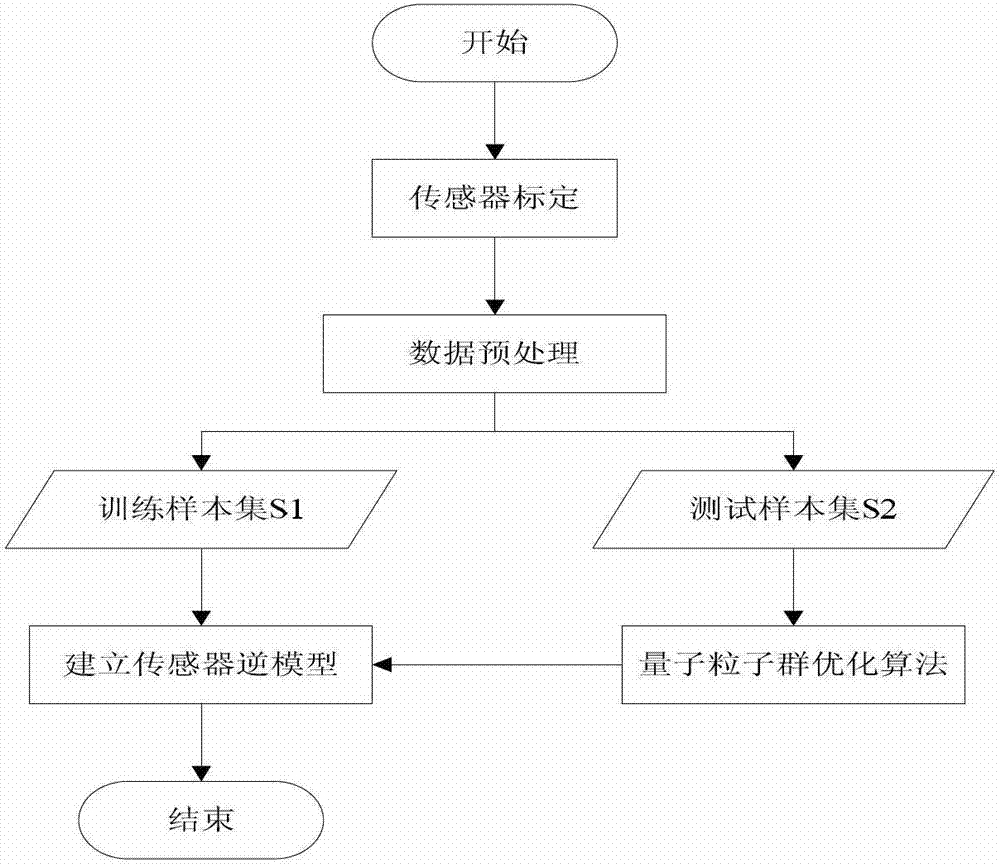

[0030] Such as figure 1 As shown, a sensor measurement method based on dual support vector machines uses sensor calibration data to establish data samples, and uses support vector machines to construct the sensor inverse model and error model respectively. The parameters of the two support vector machine models are optimized by quantum particle swarm The root mean square error and the maximum absolute error of the algorithm and model are selected and optimized, and the difference between the output of the inverse model of the sensor and the output of the error model is used as the true value of the measured value to realize the effective compensation of the nonlinear characteristics of the sensor and achieve The purpose of measuring the measurand with high precision.

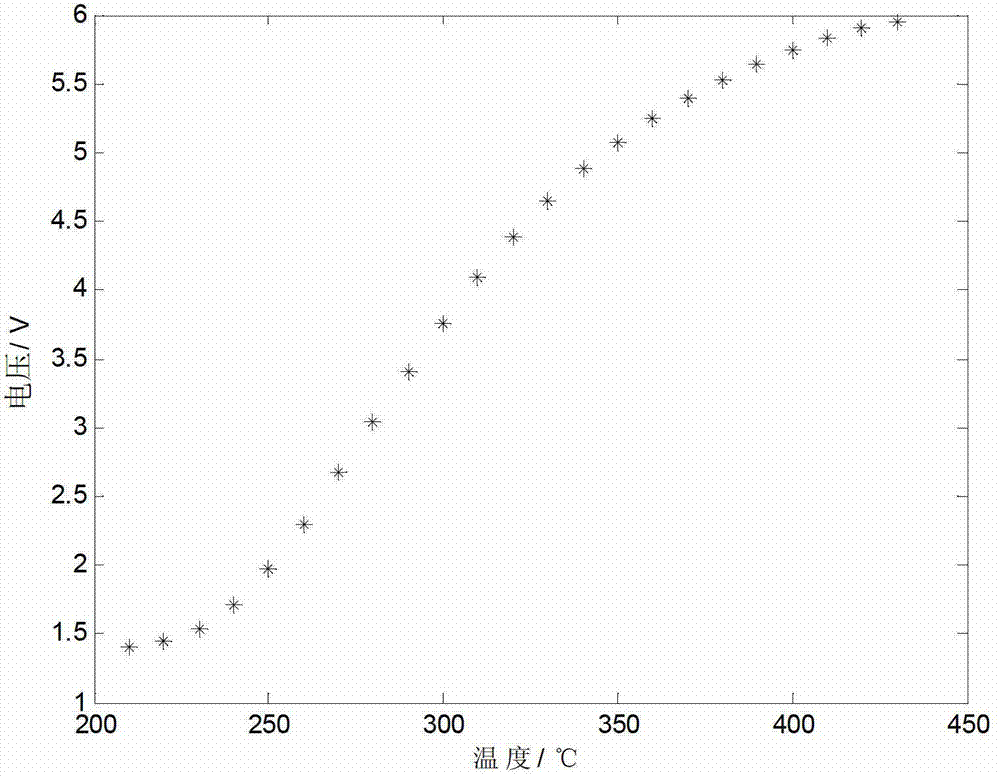

[0031] In this embodiment, a temperature sensor is used to illustrate the method, and both the inverse model and the error model of the sensor are selected and optimized using the quantum particle swarm optimiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com