Automatic detection method and equipment thereof for automotive air vent

An automatic detection and venting technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of high labor cost, large amount of labor usage, and uncertain efficiency, so as to save labor costs, Find Convenience and Efficiency Improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

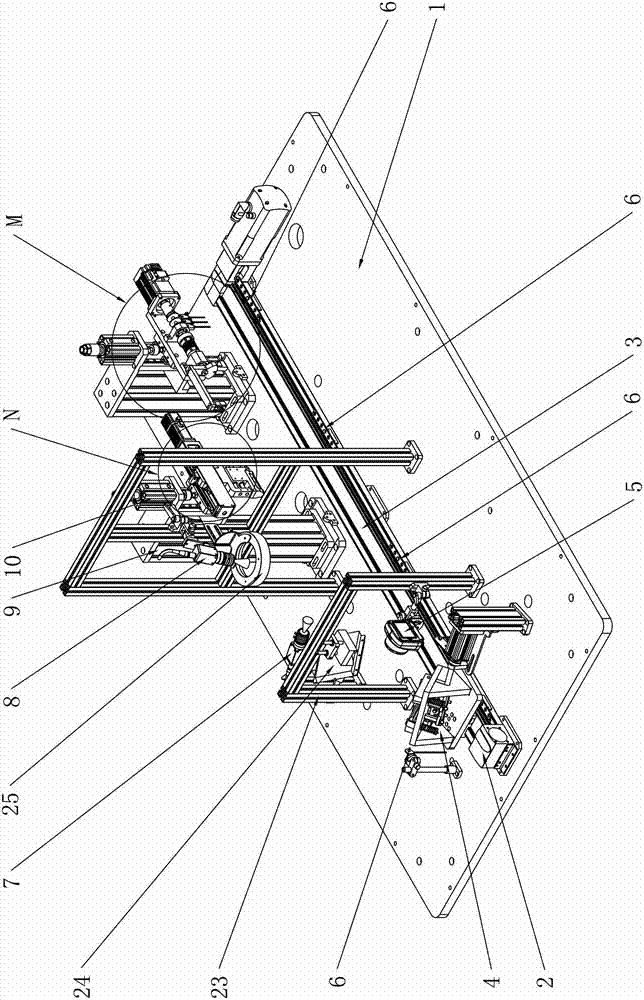

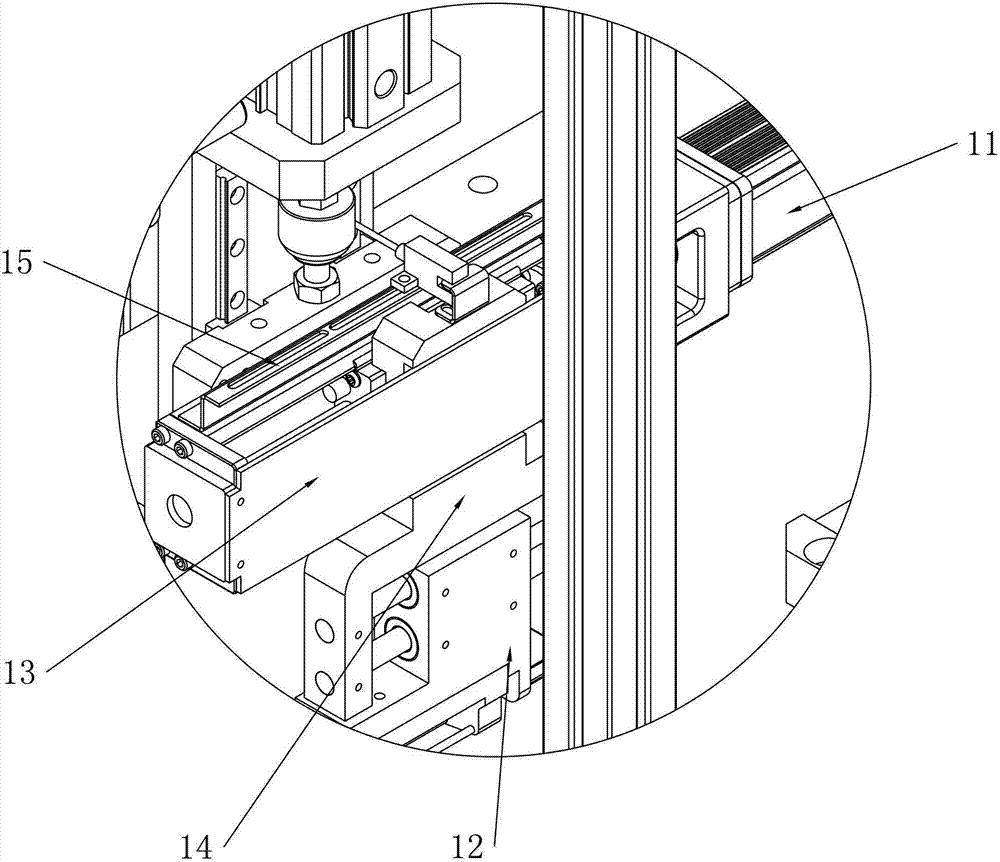

[0032] Implementation mode one: if figure 1 , 2 , Shown in 3 and 5, a kind of method for automatic detection of automobile air vent of the present invention, wherein, following steps are arranged:

[0033] (1) Install the air vent part with the barcode on the fixture 4, and scan the barcode for detection. During operation, the operator puts the air vent part with the barcode into the slot of the fixture 4, and then clicks the thermal button on the controller, and a positioning detection sensor is set on the workbench panel 1 on the side of the fixture 4. The air vent part on the fixture 4 is positioned and detected. After confirming that the air vent part is installed correctly, the barcode attached to the air vent part is scanned by the barcode scanner 5. On the one hand, the information of the air vent part is confirmed, and on the other hand , to identify the category of vent components, and prepare for missed and false detections.

[0034] (2) Missing or wrong installat...

Embodiment approach 2

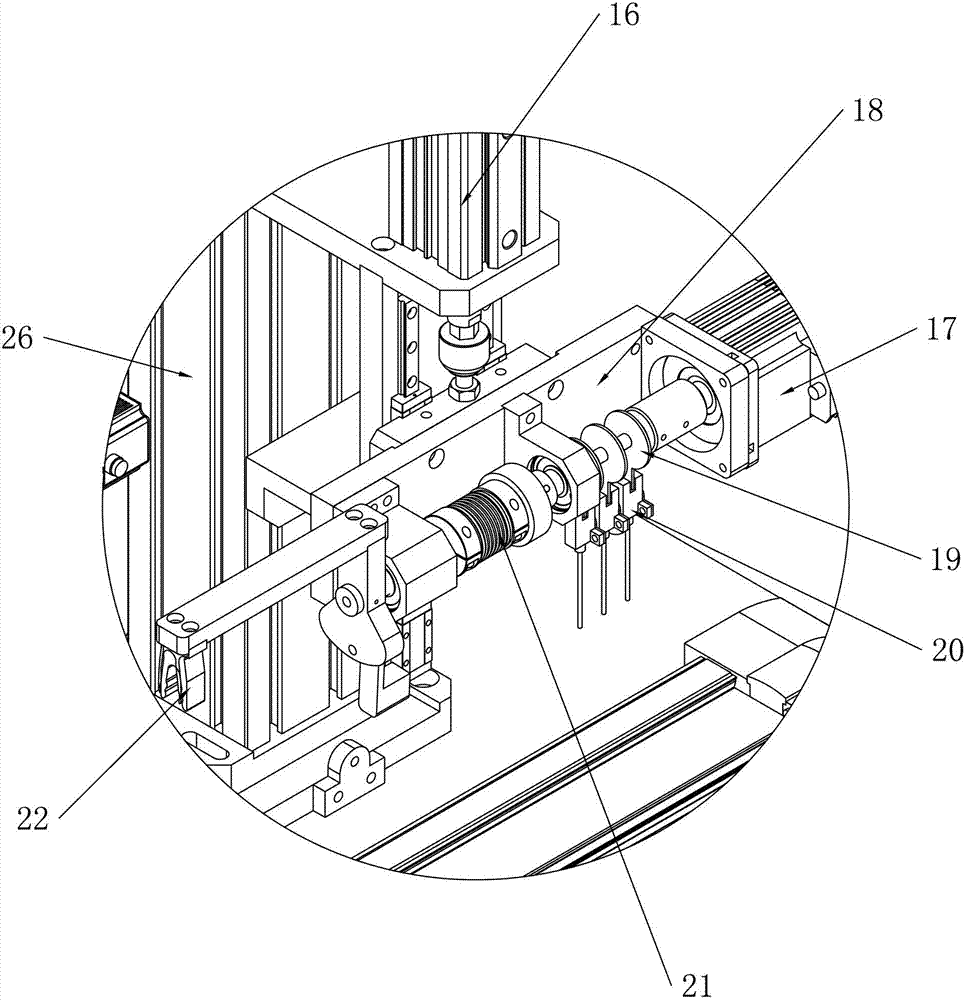

[0080] Implementation mode two: if Figure 4 and 6 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the above-mentioned leakage and misinstallation detection device of this embodiment is a CCD image sensor and a laser displacement sensor 27, and the CCD image sensor of this embodiment is as described in Embodiment 1. It is a CCD image sensor installed on the thrust detection mounting column 9, which collects images of many parts on the upper part of the air vent assembly, and then compares the images.

[0081] The above-mentioned laser displacement sensor 27 is a kind of COMS digital laser sensor. When the air vent part passes through the laser data collection place, the laser displacement sensor 27 reads the numerical value of the laser displacement to obtain the displacement change of the laser point on the air vent part. Analysis of the numerical value of the laser displacement can obtain whether there is missing or wrong installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com