Continuous and depth-adjustable sampling device

A sampling device and depth technology, which is applied in the field of iron and steel metallurgy, can solve the problems of unfixed station position and changes in sampling depth affecting test results, etc., achieve the effects of reducing the occupation of horizontal space, improving the working environment, and solving accidents caused by splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

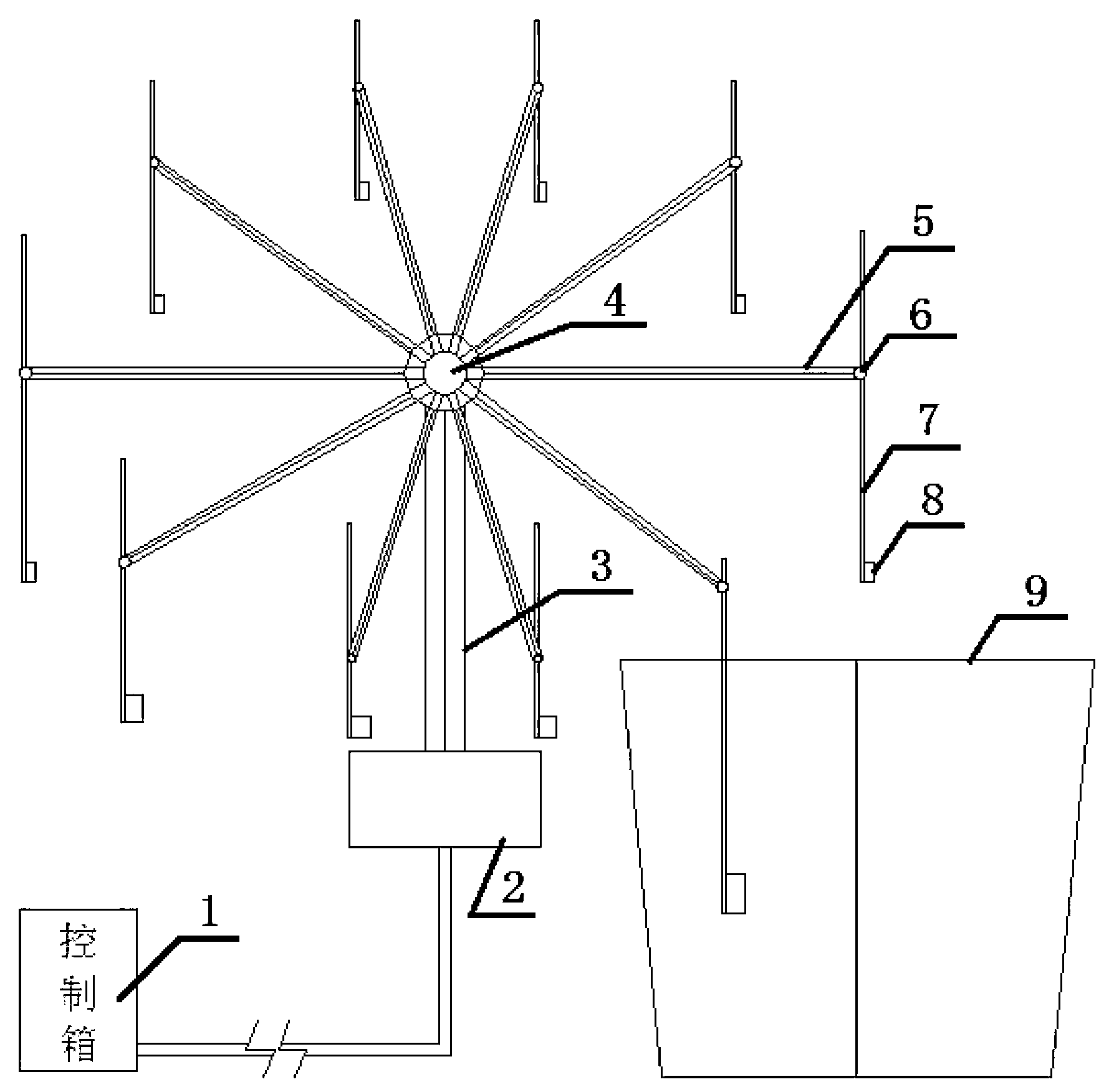

[0020] See attached figure 1 , the present invention is made up of base 1, support 2, integrated control box 3, mechanical connection shaft 4, rotating arm 5, steel wire rope 6, various style sampler 7 and ladle or ladle 8; By bolt and nut connect them.

[0021] The connection method is from bottom to top:

[0022] The bracket 3 and the base 2 are connected by bolts and nuts with a flange; the integrated control box 1 and the base 2 are connected by wires, or welded on the bracket 2; one end of the rotating arm 5 is fixed on the turntable 4; and the turntable 4 is fixed on the upper end of the bracket 3 The turntable 4 can move in a circle, and can also lift the rotating arm 5 (inspection position) and put it down (working position); the other end of the rotating arm 5 fixes the gear 6, and the gear 6 engages the measuring gun 7, which can make the measuring gun 7 move up and down; One end of the gun 7 is connected to the sampler 8, and the other end is connected to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com