Wind tower wind turbine

A wind turbine and wind guide tower technology, applied in the field of vertical shaft tower wind turbines, can solve the problems of high start-up wind speed, large installation conditions, large land occupation, and low wind utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

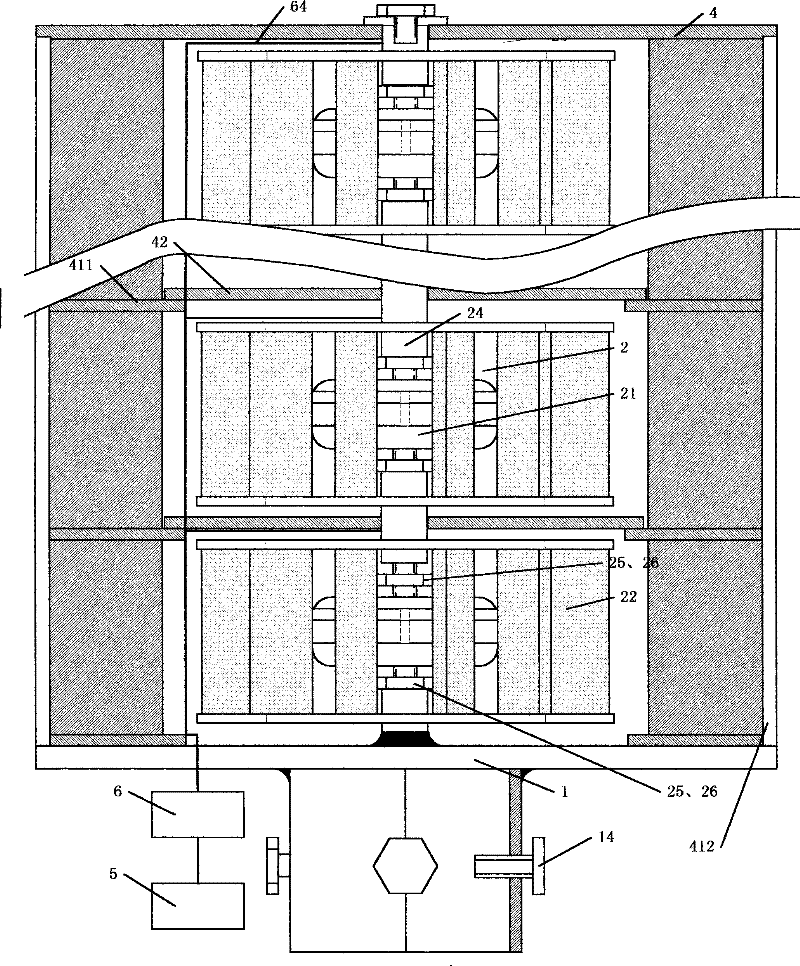

[0034] Such as figure 1 As shown, the wind guide tower type wind generator is composed of a bracket 1, a generator set 2, a wind guide shield 4, an accumulator set 5 and a control circuit 6;

[0035] Its support 1 installs and fixes the whole generator on the column. The generator set 2 and the wind guide shield 4 are fixed on the support 1 respectively, and become the main body of the wind guide tower type wind power generator.

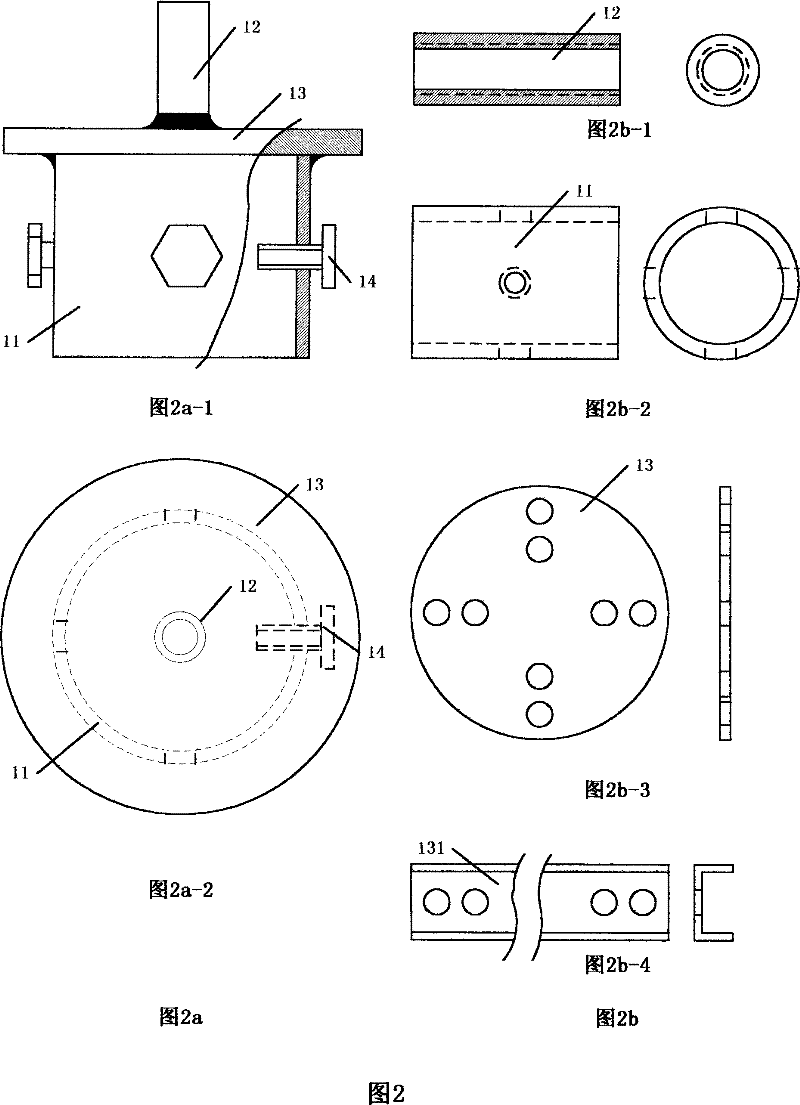

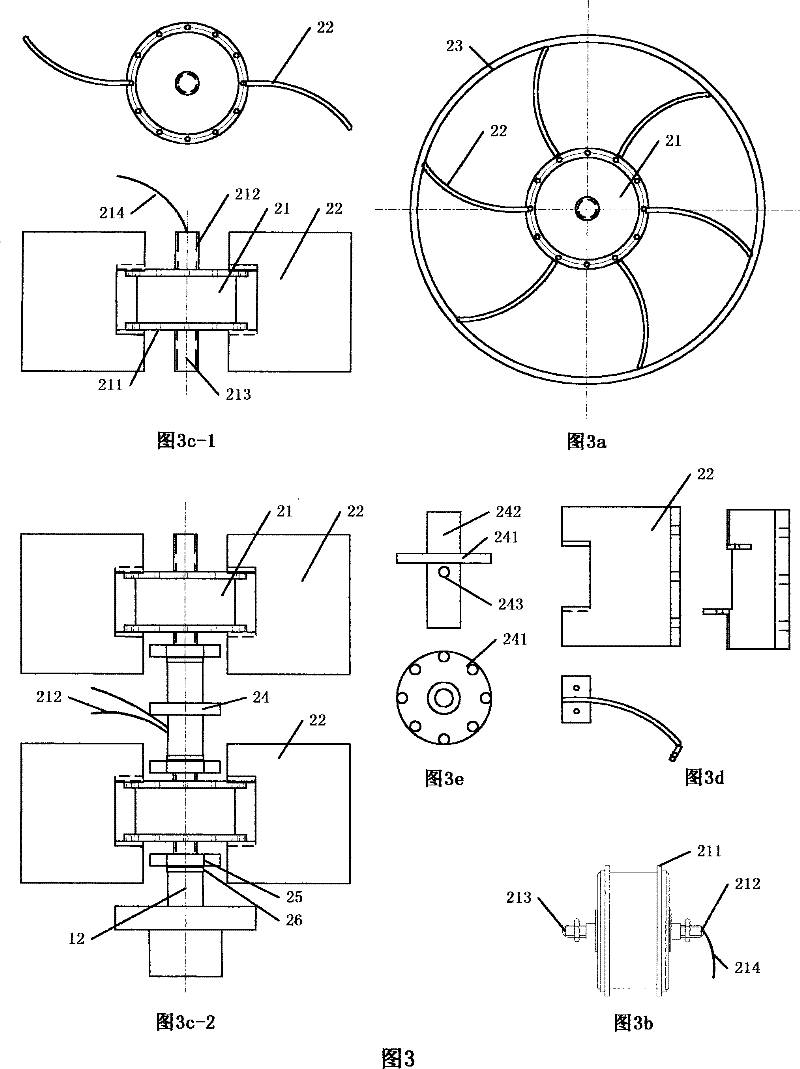

[0036] figure 2 It is an example of a bracket 1. There is a hub motor 21 mounting bushing 12 in the center of the bracket, and the wind guide shield 4 is installed on the flange plate 13 of the bracket, and the round sleeve barrel 11 is used to fix on the column. Round sleeve bucket 11, axle sleeve 12, flange plate 13 are welded into support 1. The structure of its support 1 is made into multiple styles according to the power size of the generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com