Wafer cleaning device and process thereof

A wafer cleaning and wafer technology, which is applied to electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of rising unit price of wafer manufacturing, achieve the effects of reducing manufacturing unit price, improving cleaning power, and shortening the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, configurations of embodiments of the present invention will be described with reference to the drawings.

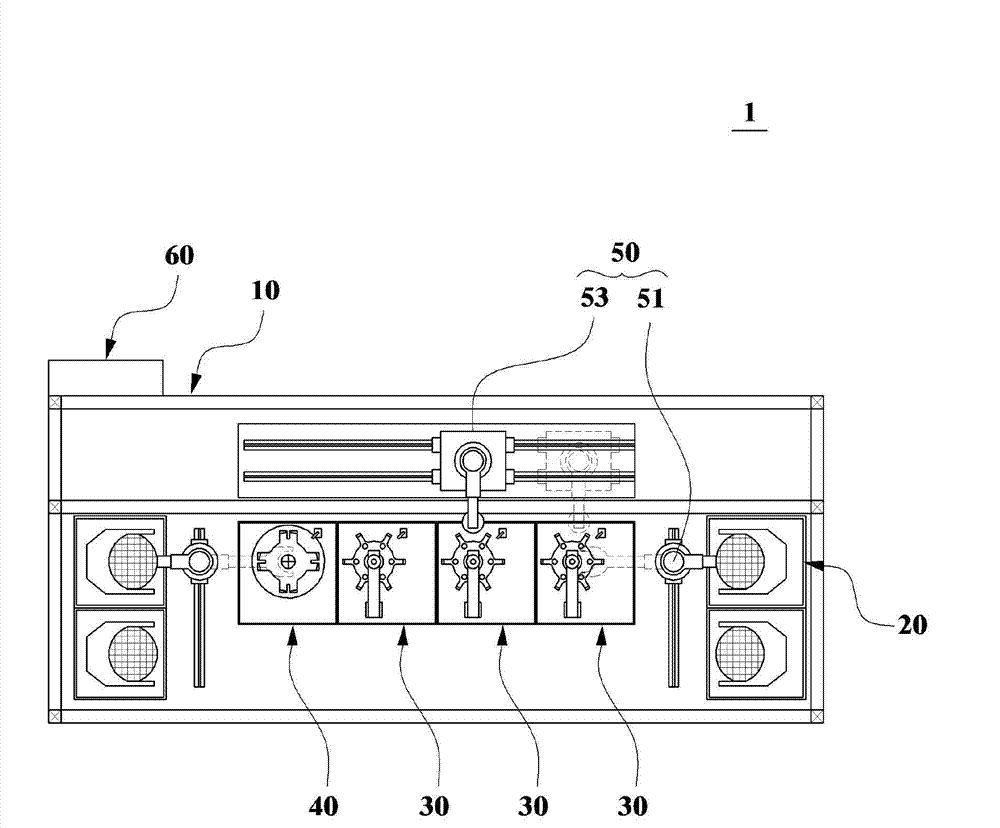

[0030] First, refer to figure 2 The wafer cleaning apparatus 1 according to the embodiment of the present invention generally includes a setting unit 10 , a first cleaning unit 20 , a second cleaning unit 30 , a drying unit 40 , a transfer unit 50 and a control unit 60 .

[0031] First, the setting part 10 is a structural component for the first cleaning part 20 , the second cleaning part 30 , the drying part 40 , the transfer part 50 and the control part 60 hereinafter, and is formed by combining horizontal frames and vertical frames.

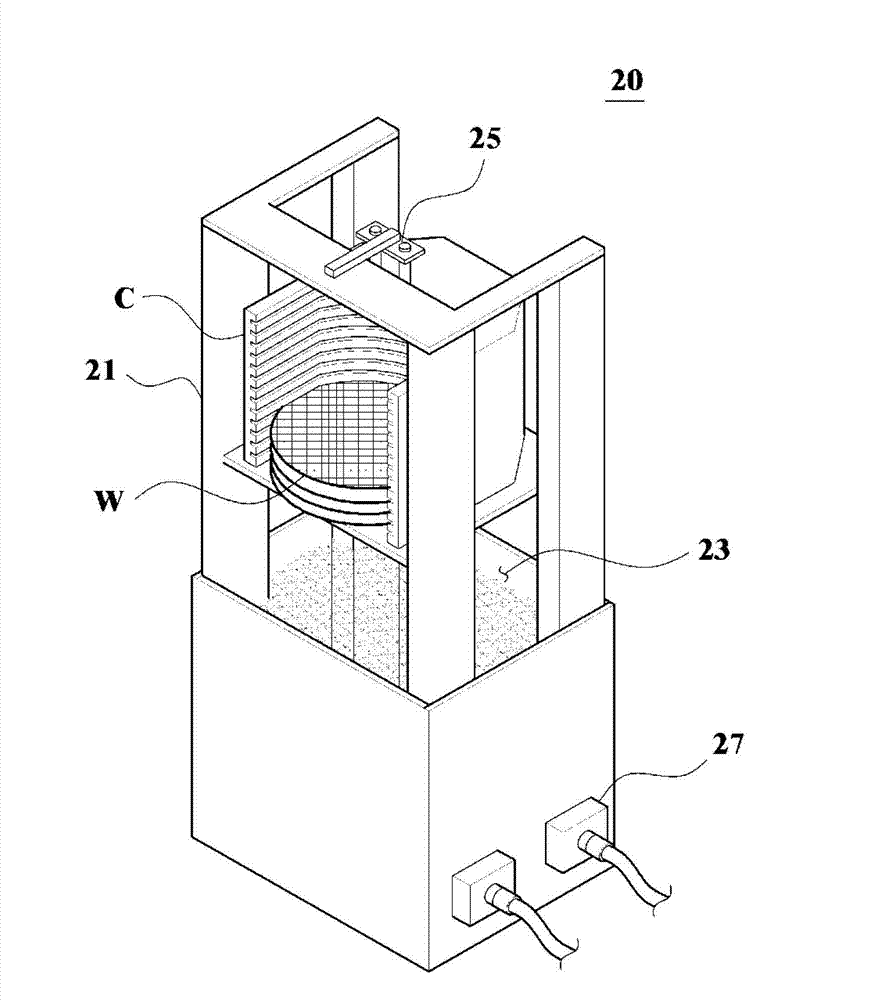

[0032] In addition, the first cleaning unit 20 is fixedly installed on the installation unit 10. The first cleaning unit 20 is a component for cleaning the wafer W stored in the cassette C using ultrapure water and nitrogen foam, and includes a immersion unit 21 and a foam nozzle. (Bubble Nozzle) 27.

[0033] here, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com