Method for directly identifying continuous time model of thyristor control reactor (TCR)-type reactive compensation device

A technology of compensation device and identification method, which is applied in the direction of reactive power adjustment/elimination/compensation, flexible AC transmission system, etc., and can solve the problems of lack of reactive power compensator mathematical model and designers' inability to use it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

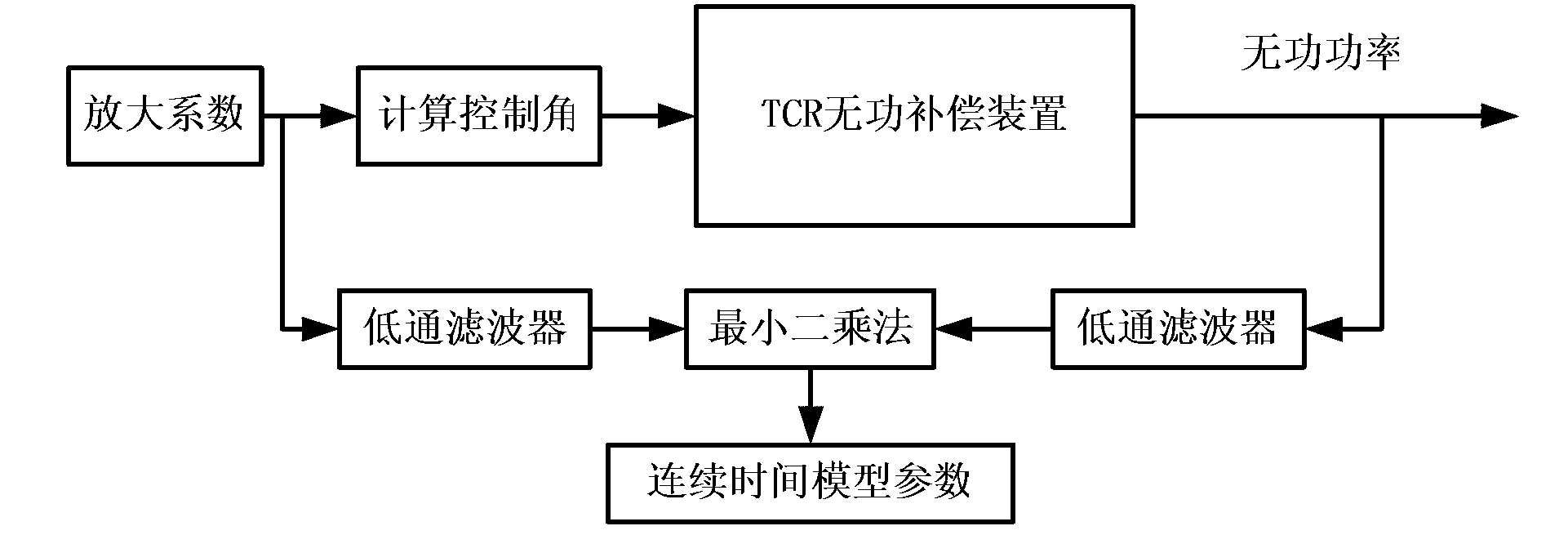

[0028] figure 1 It is a schematic diagram of an embodiment of the present invention, which includes the following steps: S1, sampling the input data, three-phase current and three-phase voltage data of the reactive power compensation device; S2, using the instantaneous reactive power theory to calculate the output of the reactive power compensation device The reactive power of the reactive power, the input data sampled at each moment and the corresponding reactive power data are saved as a data set; S3, design a low-pass filter to filter the input data and reactive power data obtained in the step S2 to obtain a new input data and reactive power data, and save the filtered new input data and reactive power data as a data set; S4, use the least squares method to identify model parameters for the filtered data set to obtain accurate reactive power compensation Device continuous-time model.

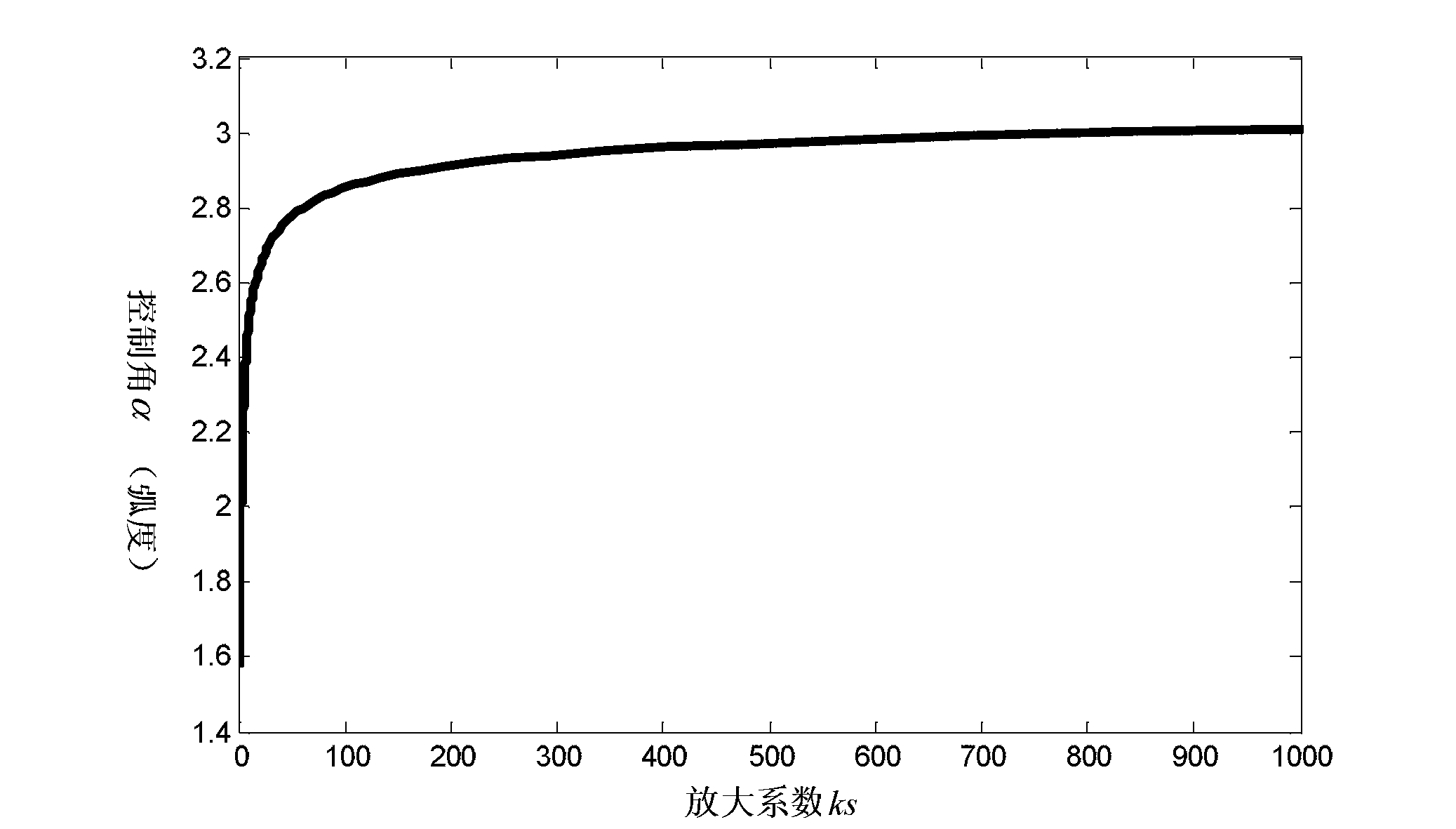

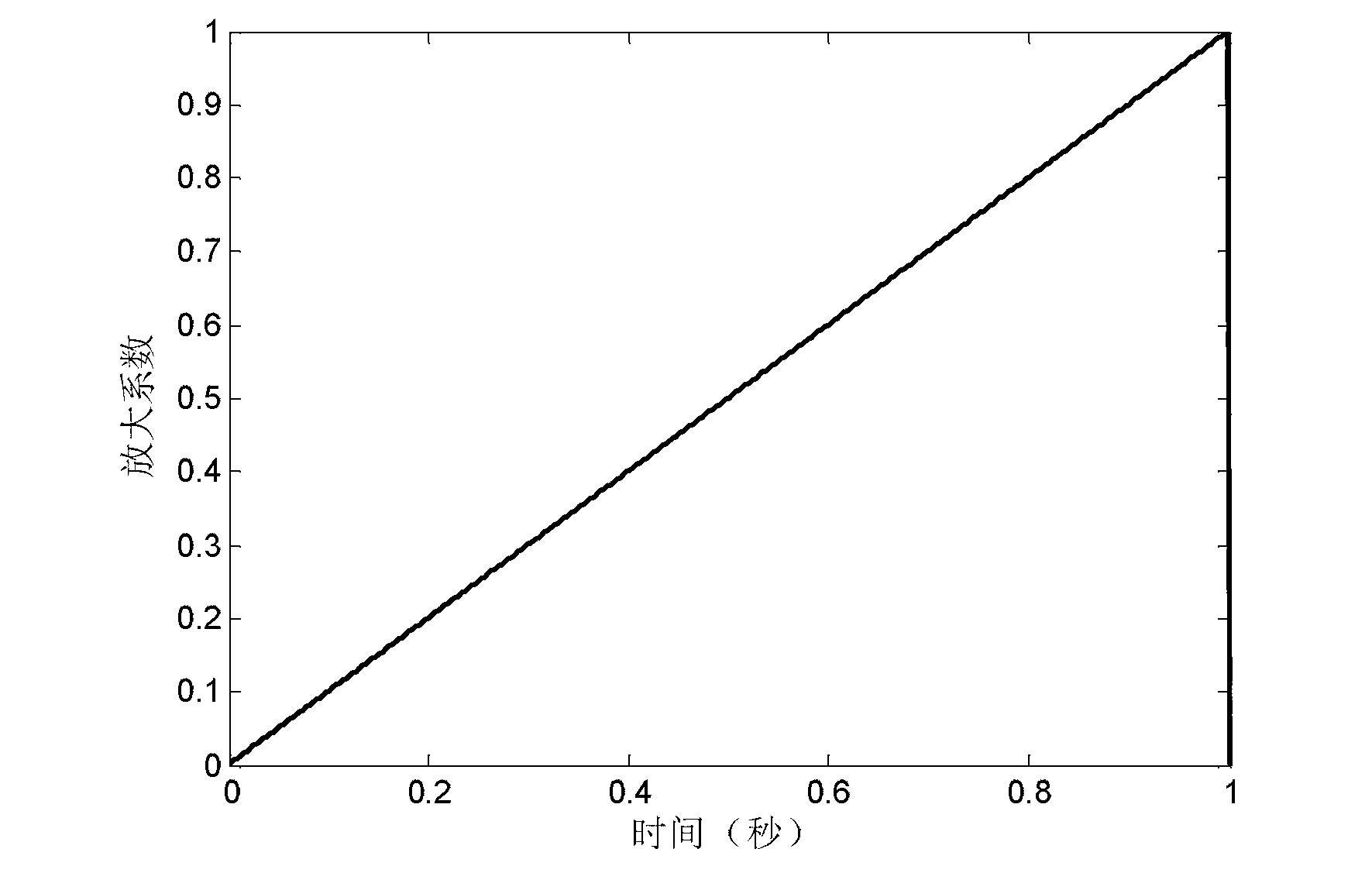

[0029] In the step S1, let the sampling frequency be f s , sampling period T s =1 / f s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com