Synthetic resin container

A synthetic resin and container technology, applied in the field of synthetic resin containers, can solve problems such as deformation, and achieve the effects of high strength, excellent aesthetics, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

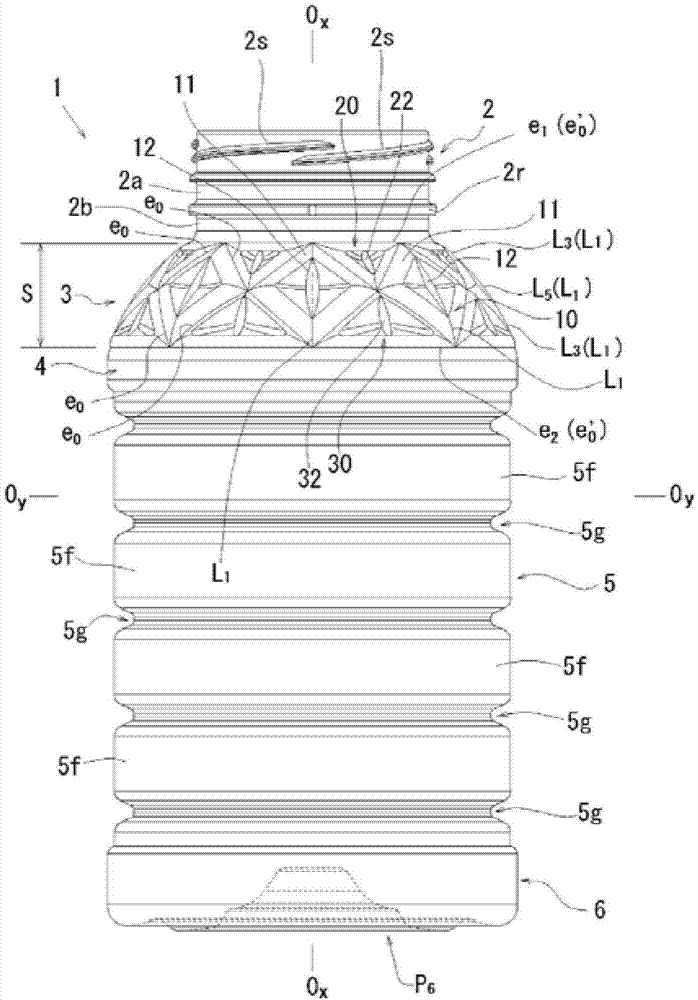

[0064] Hereinafter, the bottle (bottle) 1 which is one aspect of this invention is demonstrated in detail, referring drawings.

[0065]The bottle 1 is a blow-molded product formed by blow-molding a preform made of, for example, polyethylene terephthalate (PET) as a raw material.

[0066] The mouth portion 2 includes a mouthpiece portion 2a formed with a male thread portion 2s for attaching a cap (not shown). The base part 2b is integrally connected to the mouthpiece part 2a via a choker ring 2r.

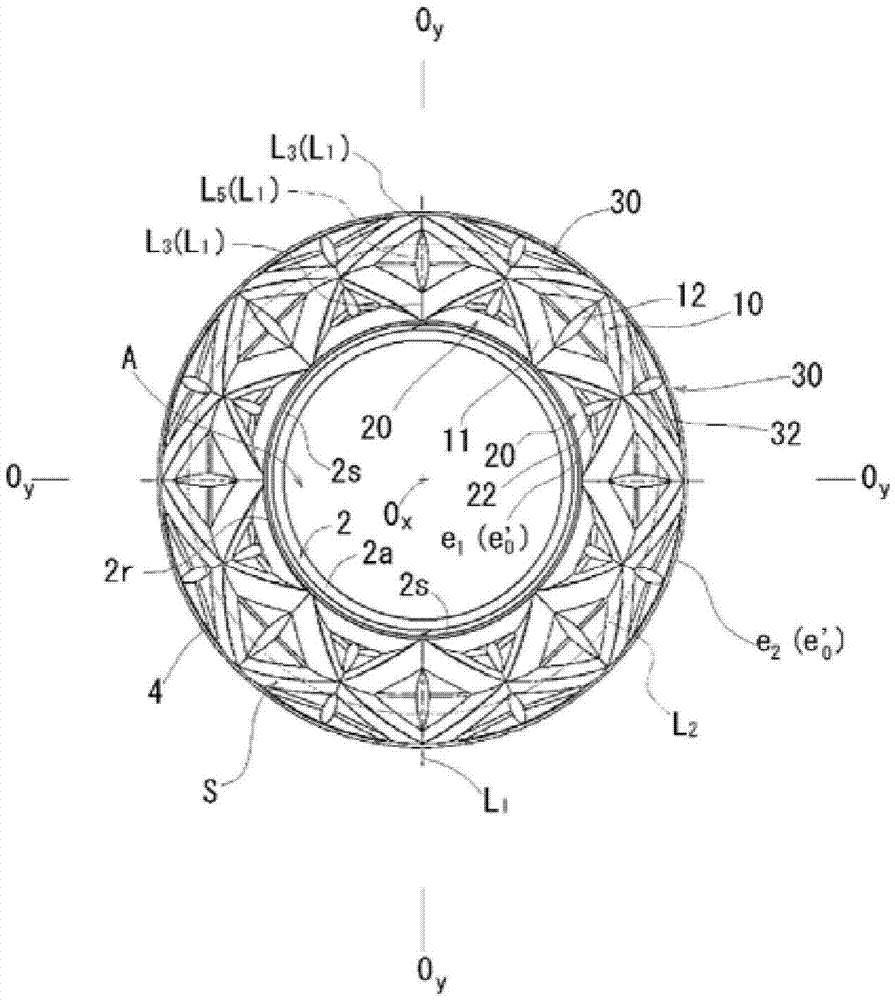

[0067] The shoulder portion 3 is integrally connected to the base portion 2b of the mouth portion 2 . The shoulder portion 3 includes a dome-shaped region S that bends toward the outside of the bottle (diametrically outward) and expands as it goes from the base portion 2b toward the trunk portion 5 .

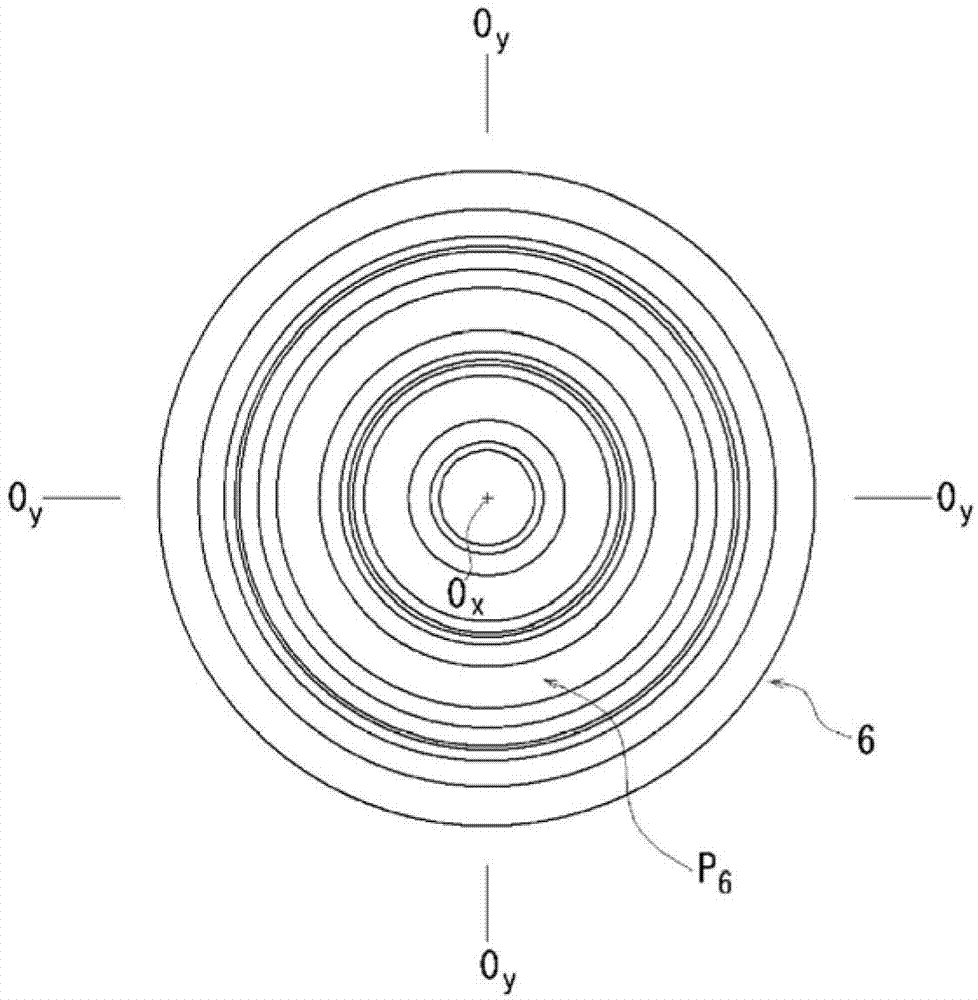

[0068] Such as figure 1 As shown, the dome-shaped area S is set at the mouth side edge e 1 with the side edge of the trunk e 2 Within the ring-shaped area divided, the mouth side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com