Process and apparatus for manufacturing polycrystalline silicon ingots

A technology of polycrystalline silicon ingots and equipment, applied in lighting and heating equipment, polycrystalline material growth, semiconductor/solid-state device manufacturing, etc., can solve problems such as phase boundary bending and temperature curve will not be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In the following description, the terms top, bottom, left and right and their corresponding terms are for the figures and should not be considered as limiting terms, these terms are for the preferred embodiments in the following description. In general terms used to describe angles and configurations shall include deviations of up to 10° and preferably up to 5°, unless other ranges are mentioned.

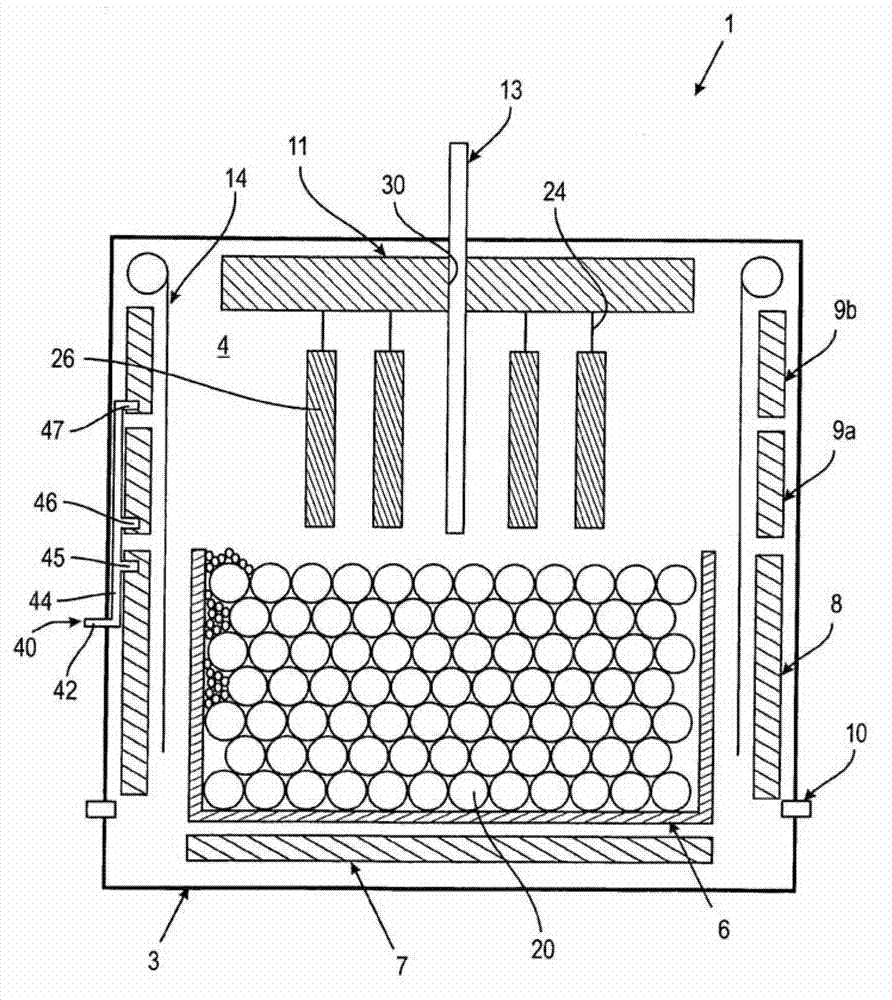

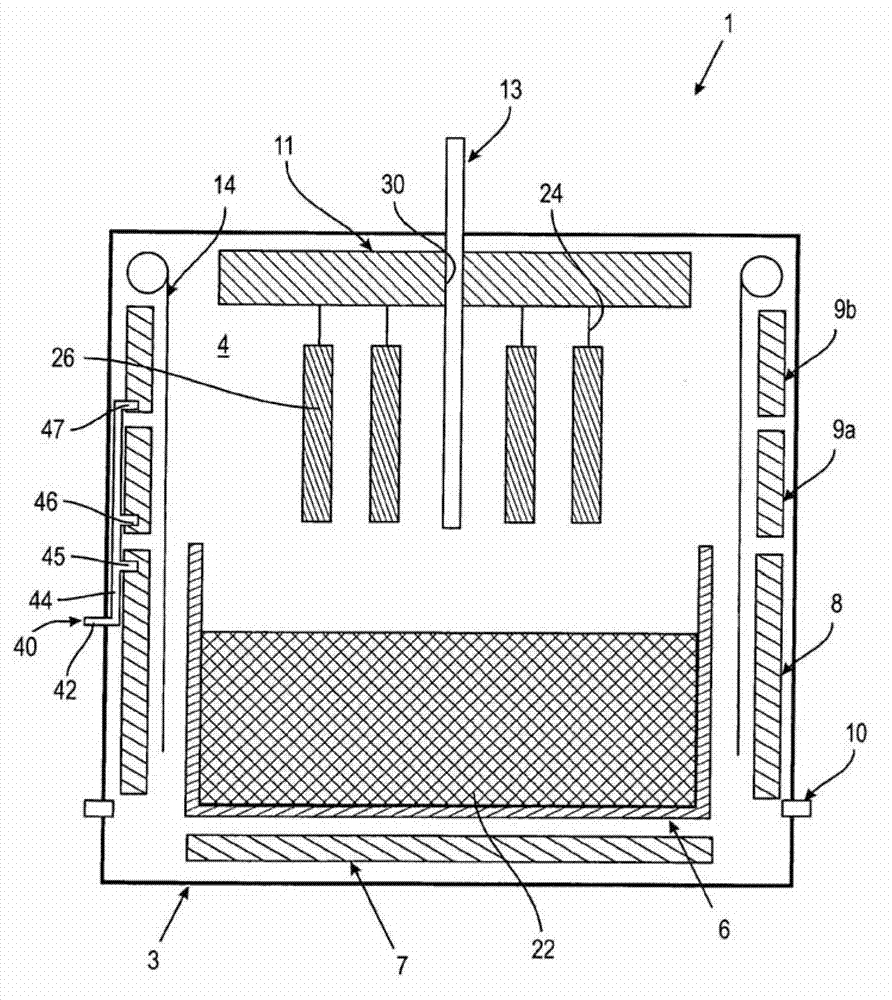

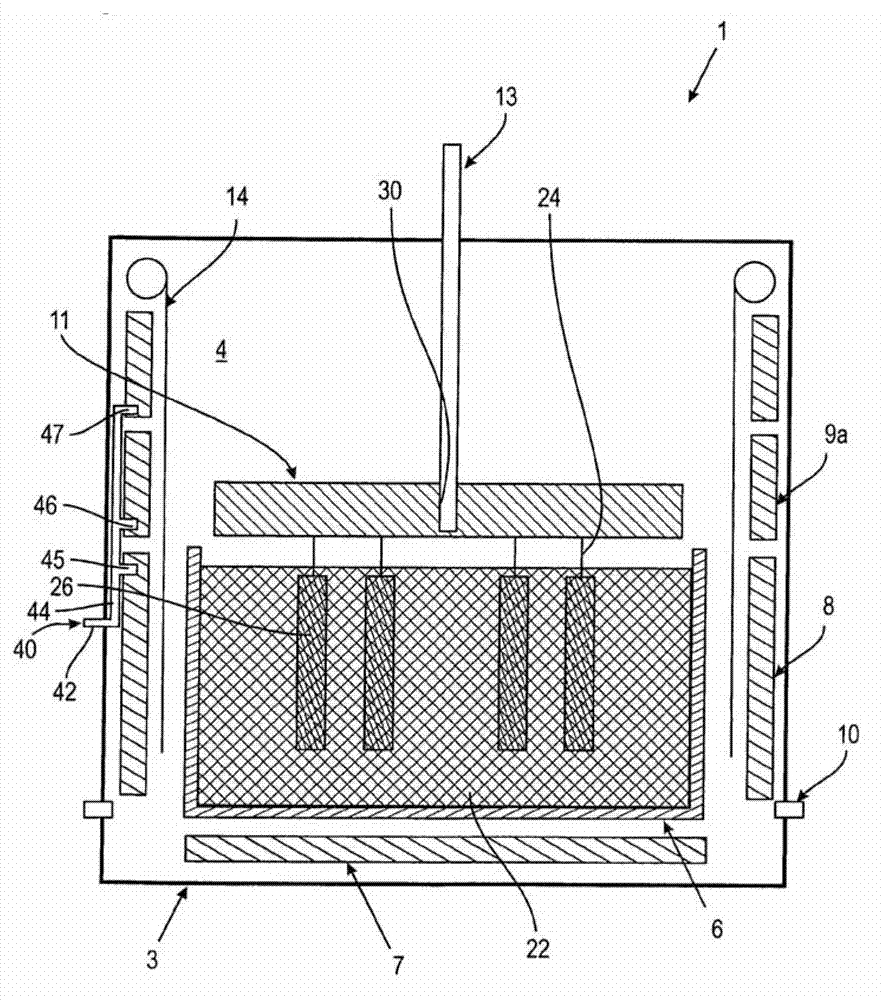

[0031] figure 1 Shown is a schematic cross-sectional view of an apparatus 1 for producing polycrystalline silicon ingots.

[0032] The apparatus 1 generally comprises an isolation box 3 delimiting a process chamber 4 . In the process chamber 4, a holding unit (not shown in detail) for holding a crucible 6, a bottom heating unit 7, an optional side heating unit 8 and two stacked diagonal heating units 9a and 9b are provided. At least one gas outlet 10 is provided at the lower end of the side wall of the isolation box 3 . A plate element 11 is arranged above the holder of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com