Woven zipper teeth chain belt

A technology of zipper teeth and zipper tape, which is applied in the direction of warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of reduced appearance of coated products and achieve the effect of improving flexibility and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to embodiment described below at all. Various changes can be made as long as it has substantially the same structure as the present invention and achieves the same effect.

[0044] For example, the continuous element row of the fastener stringer described in the following embodiments is formed by forming a single filament into a coil shape, but the present invention is not limited thereto, and may be formed by forming a single filament into a coil shape. Serrated and formed.

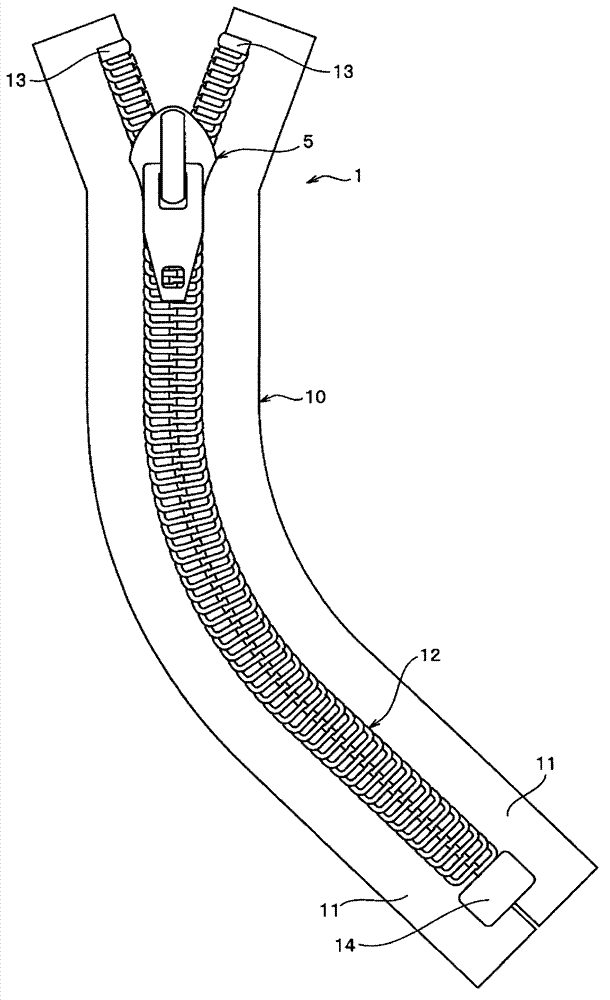

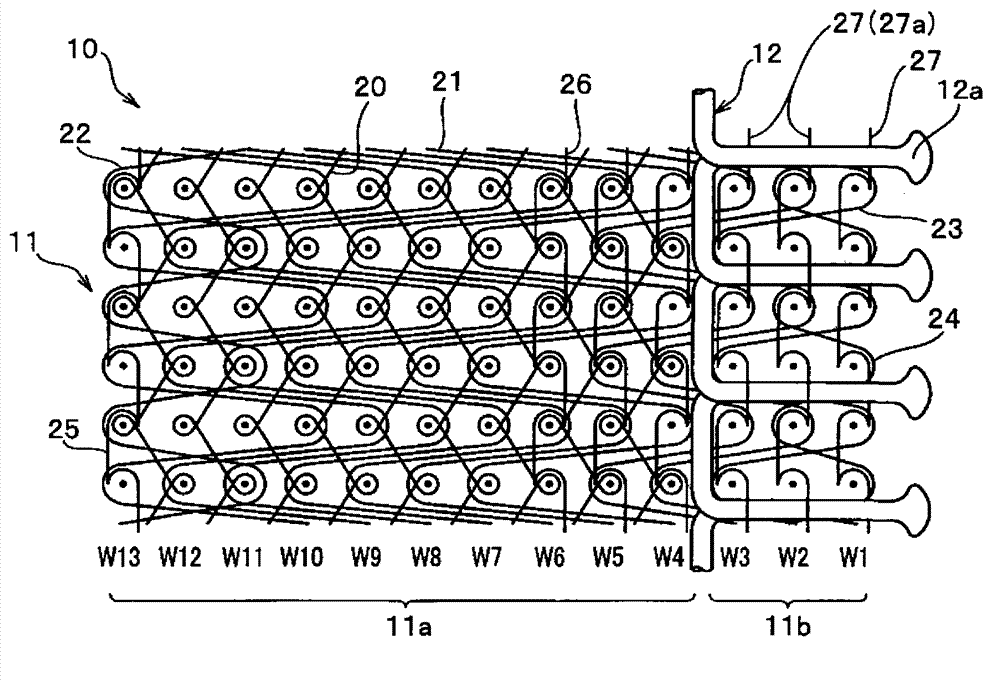

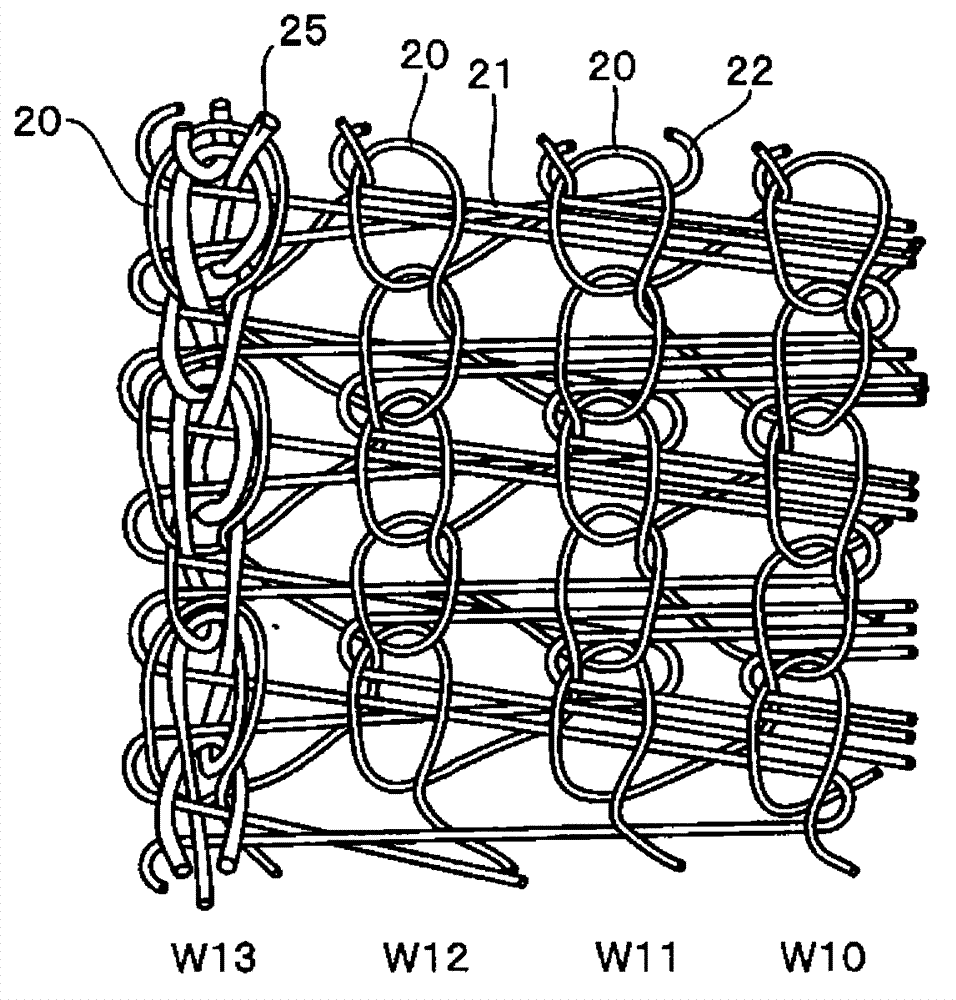

[0045] figure 1 It is a front view which shows the slide fastener comprised using the knitted fastener stringer of this invention. also, figure 2 and image 3 Indicates the weaving structure of the zipper tape before the chain-shaped braiding yarn for reinforcement in the woven zipper stringer is melted, Figure 5 and Image 6 It shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com