Artificial cartilage and its production method

A manufacturing method and cartilage technology, which can be used in bone diseases, medical science, prostheses, etc., can solve the problem of no compounding, and achieve the effects of excellent self-organization, simple manufacturing, and excellent biological affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

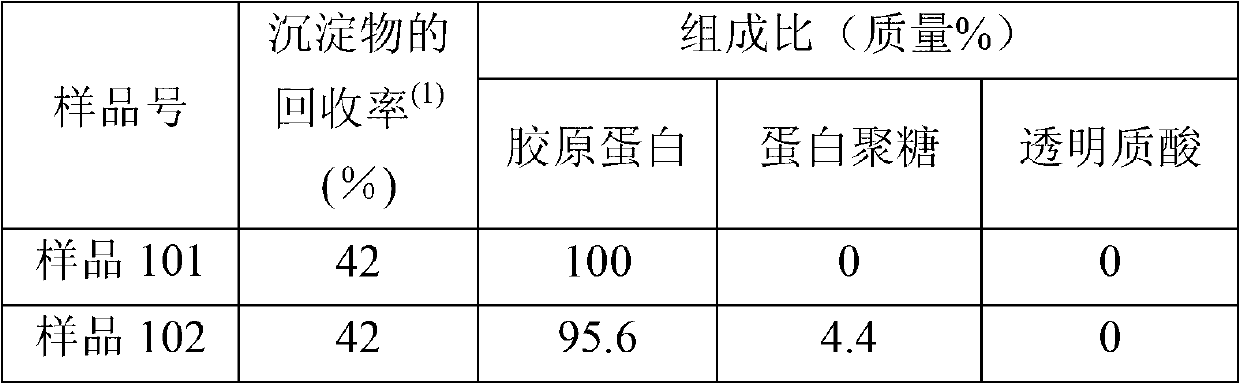

preparation example Construction

[0035] (A) Preparation of the first and second compositions

[0036] In the process of preparing the first composition, the mixing ratio (mass ratio) of hyaluronic acid and collagen is preferably 10000:1 to 1:10000, more preferably 5000:1 to 1:5000, and most preferably 15:1 to 1 : 15. It is preferable to use a substance obtained by pre-dissolving collagen in dilute hydrochloric acid (a concentration of about 5 to 50 mM) at a concentration of 0.1 to 20% by mass. In addition, it is preferable to use a substance obtained by dissolving hyaluronic acid in sterile water (water for injection, etc.) at a concentration of 0.1 to 20% by mass. It is preferable to mix the hyaluronic acid aqueous solution and the collagen aqueous solution at 3-25°C.

[0037] In the step of preparing the second composition, the mixing ratio (mass ratio) of proteoglycan and collagen is preferably 10000:1 to 1:10000, more preferably 5000:1 to 1:5000, most preferably 10:1 to 1 : 10. It is preferable to use a su...

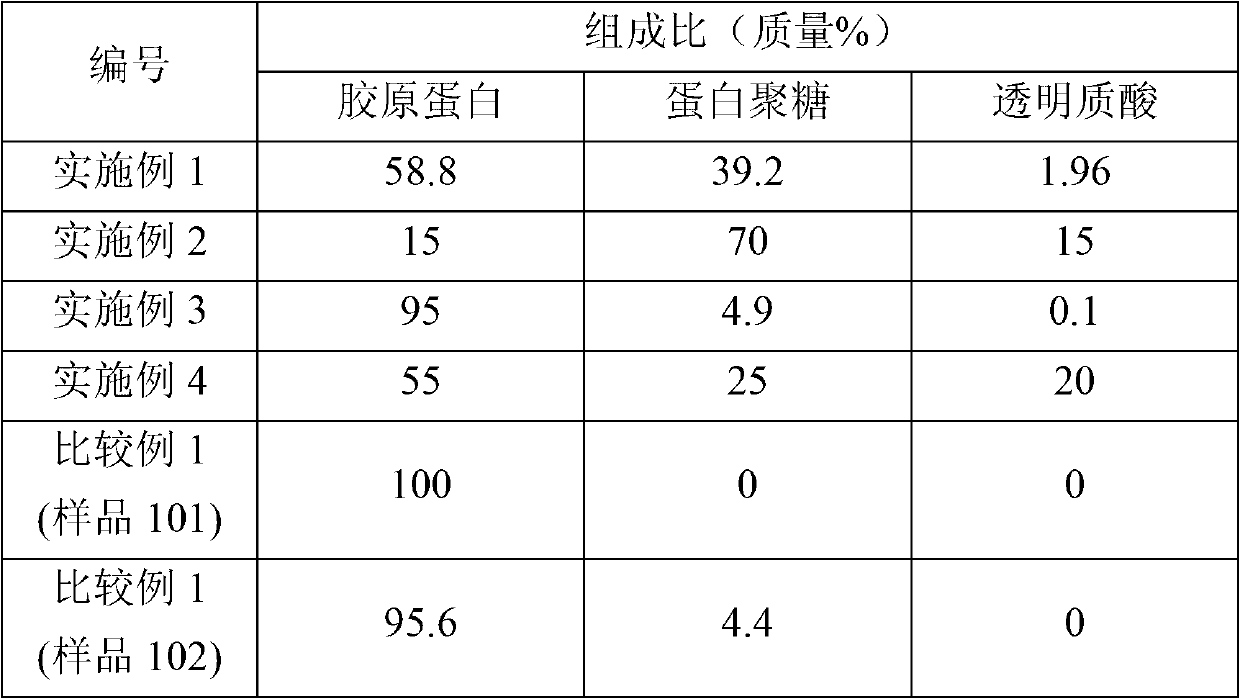

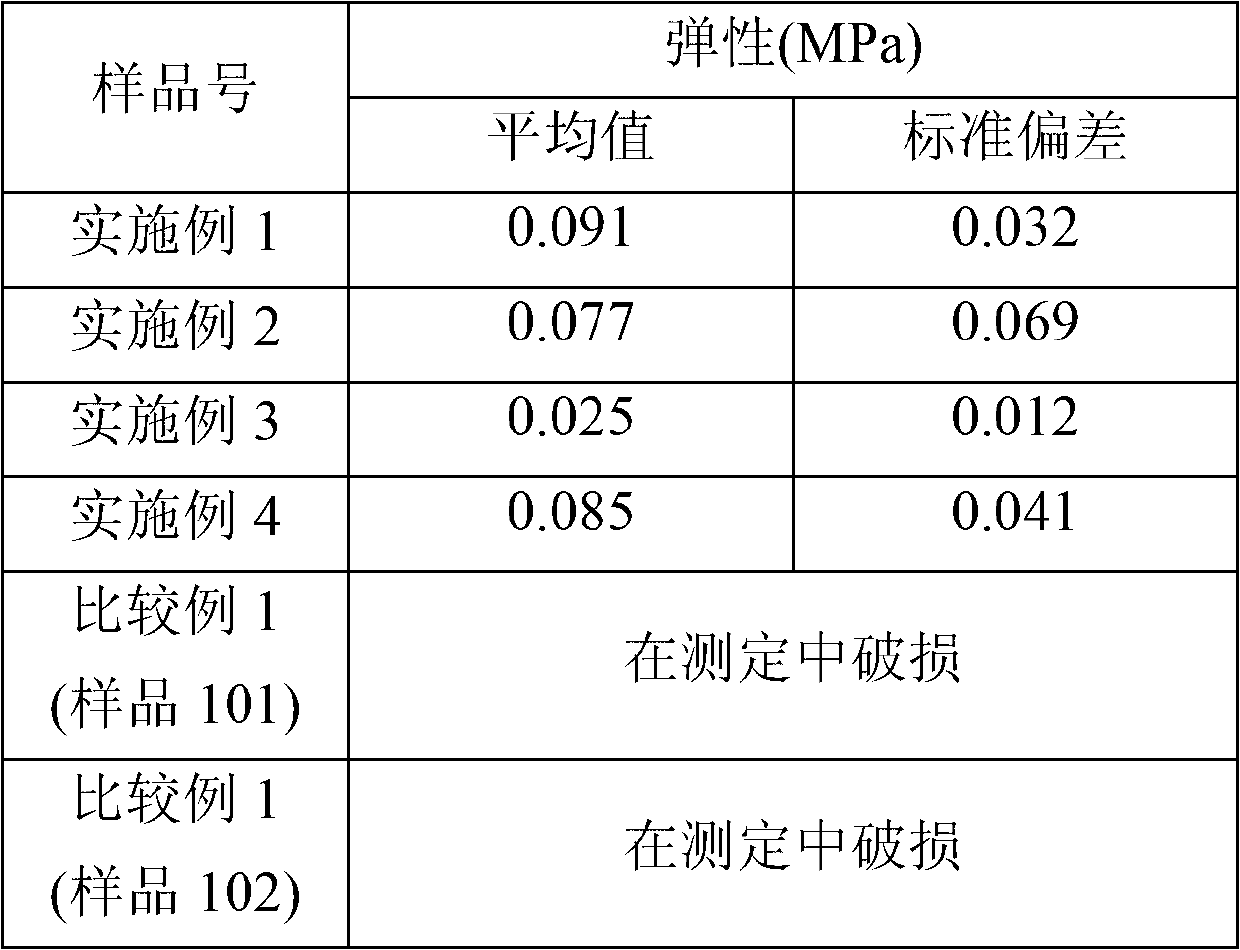

Embodiment 1

[0072] (1) Preparation of raw material solution

[0073] The collagen was dissolved in 5 mM hydrochloric acid to prepare an aqueous collagen solution with a concentration of 1% by mass. In addition, proteoglycan was dissolved in water for injection to prepare an aqueous solution of proteoglycan with a concentration of 1% by mass. In addition, hyaluronic acid was dissolved in water for injection to prepare an aqueous hyaluronic acid solution with a concentration of 0.1% by mass. In addition, these preparations were all performed at 4°C.

[0074] (2) Mixing of raw materials

[0075] Mix the above-mentioned collagen aqueous solution and proteoglycan aqueous solution at 1:1 (mass ratio), and stir with a mixer to obtain a mixed solution A. Similarly, the above-mentioned collagen aqueous solution and the hyaluronic acid aqueous solution were mixed at 1:1 (mass ratio), and stirred with a mixer to obtain a mixed solution B. Mix the mixtures A and B at 2:1 (mass ratio), and stir for 1 min...

Embodiment 2

[0087] (1) Preparation of raw material solution

[0088] The collagen was dissolved in 5 mM hydrochloric acid to prepare an aqueous collagen solution with a concentration of 1% by mass. Proteoglycan was dissolved in water for injection to prepare an aqueous solution of proteoglycan with a concentration of 1% by mass. In addition, hyaluronic acid was dissolved in water for injection to prepare an aqueous solution of hyaluronic acid with a concentration of 0.2% by mass. In addition, these preparations were all performed at 4°C.

[0089] (2) Mixing of raw materials

[0090] 22.5 mL of the prepared collagen aqueous solution, 105 mL of the proteoglycan aqueous solution, and 112.5 mL of the hyaluronic acid aqueous solution were mixed, and stirred for 1 minute with a homogenizer at a rotation speed of 2,000 rpm. Stirring was performed while keeping the temperature of the sample at 5°C.

[0091] (3) Freeze drying

[0092] The obtained mixture was grouted in a tray, frozen at -80°C for 12 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com