Steel pipe inner welding slag flushing device

A technology for flushing devices and steel pipes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of complex equipment structure, difficult maintenance, large size, etc., and achieves small size, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

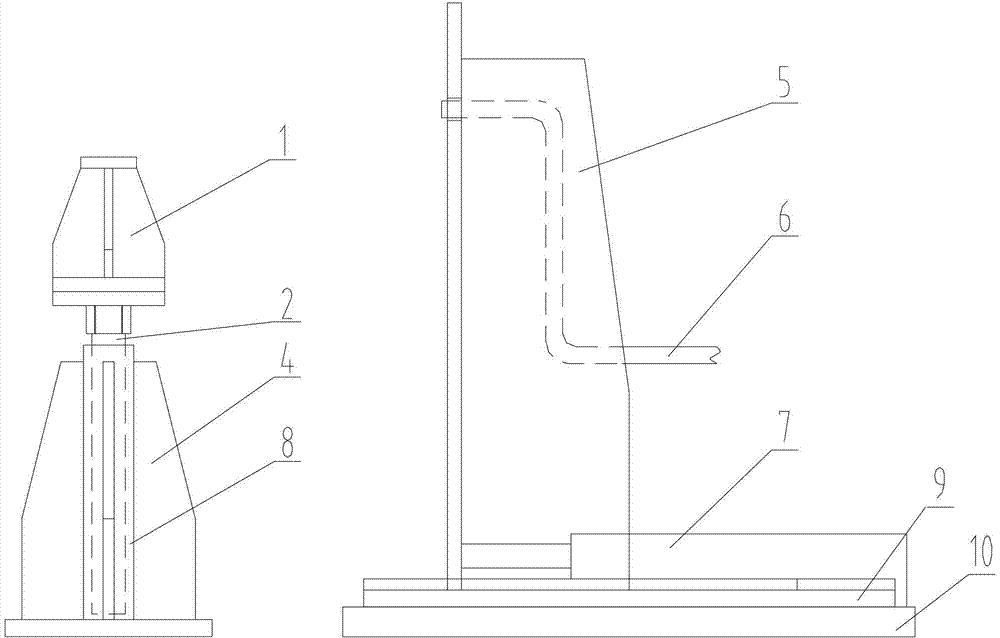

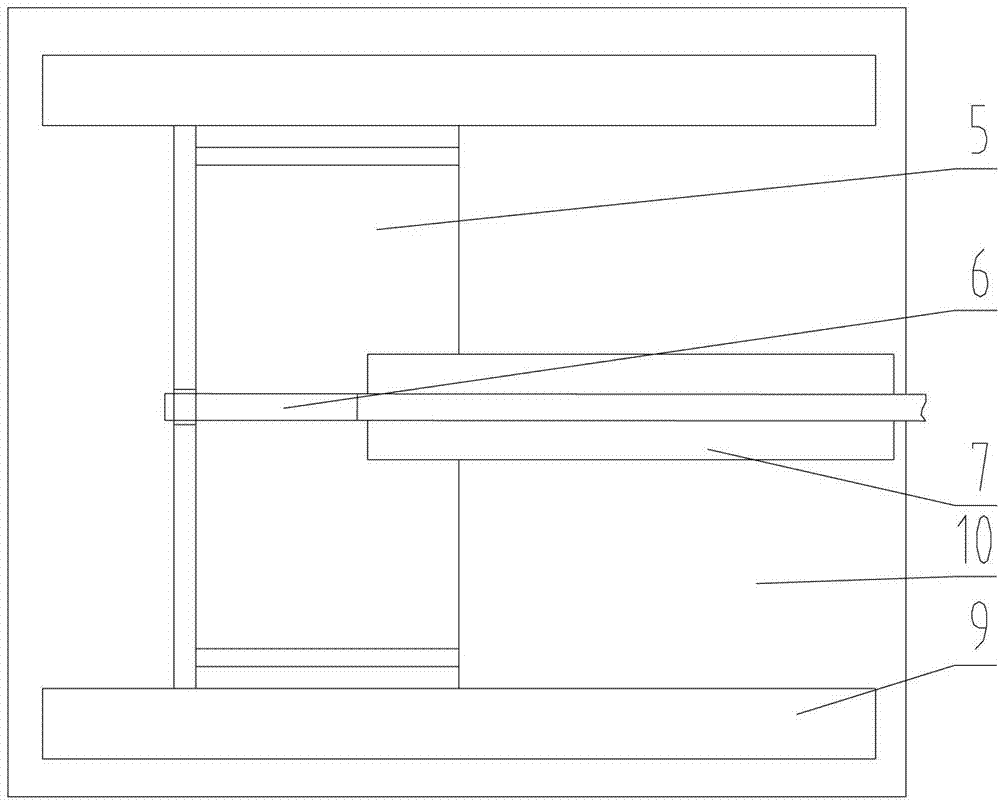

[0020] The specific embodiment of the present invention is shown in the attached drawings. Its structure is that the steel pipe inner welding slag washing device includes a steel pipe support device and a washing device; one end of the steel pipe is placed on the steel pipe support device, and the steel pipe support device is raised to lift the steel pipe After lifting, a steel pipe support device is formed with a high end and a low inclination angle at the other end; the flushing device is placed at the steel pipe mouth of one end of the steel pipe support device, and flushing is performed at the steel pipe mouth.

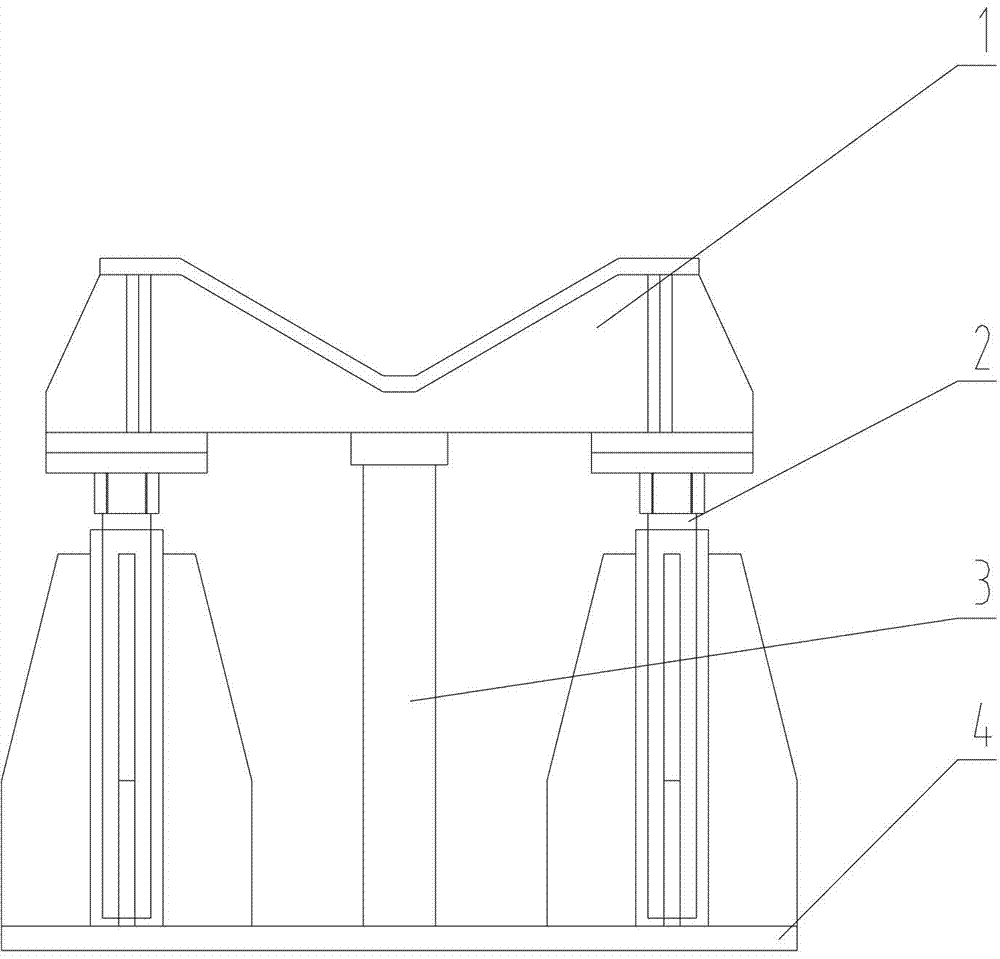

[0021] The steel pipe supporting device includes a bracket 1, a guide column 2, a hydraulic cylinder I3, a bracket base 4, and a guide post holder 8; the bracket base 4 is equipped with two guide post holders 8, and the guide post holder 8 is equipped with guide post holders. Column 2, the upper part of the guide column 2 is installed on the lower part of the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com