Blanking die structure

A technology for blanking molds and mold bases, applied in forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effects of improving blanking efficiency and finished product quality, smooth feeding, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

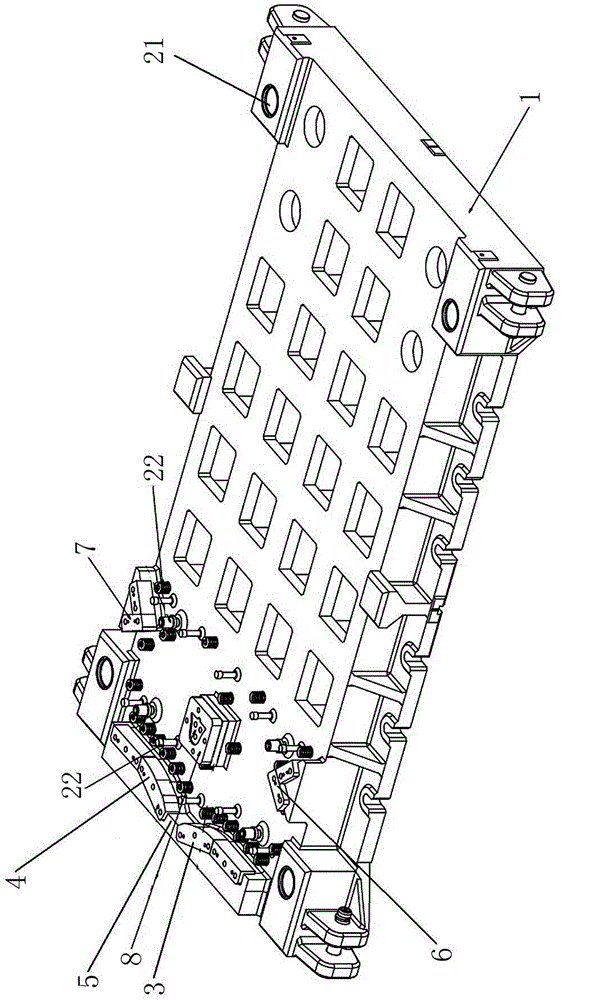

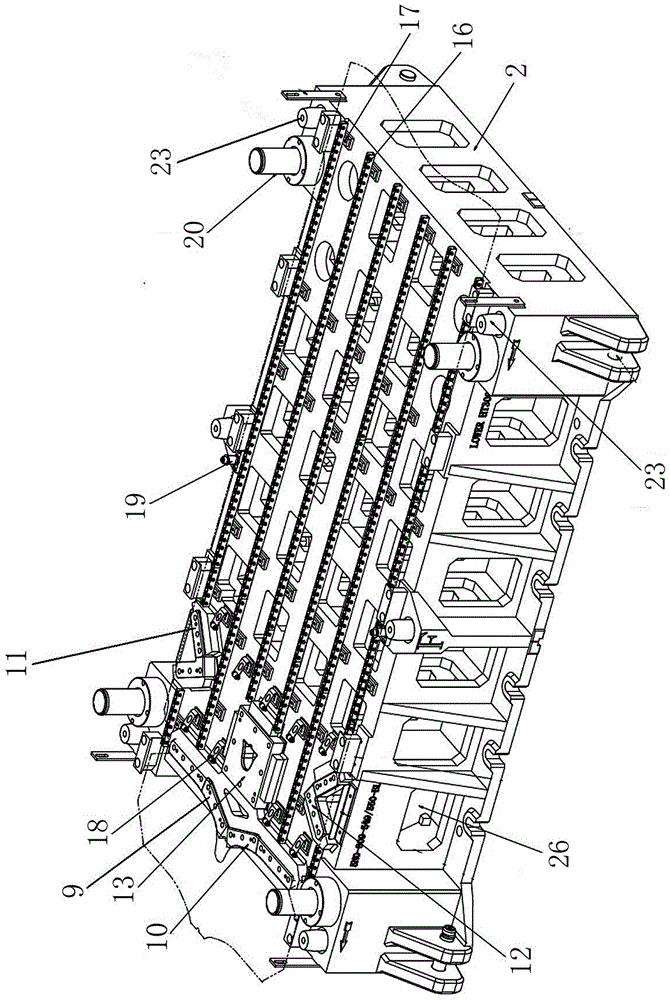

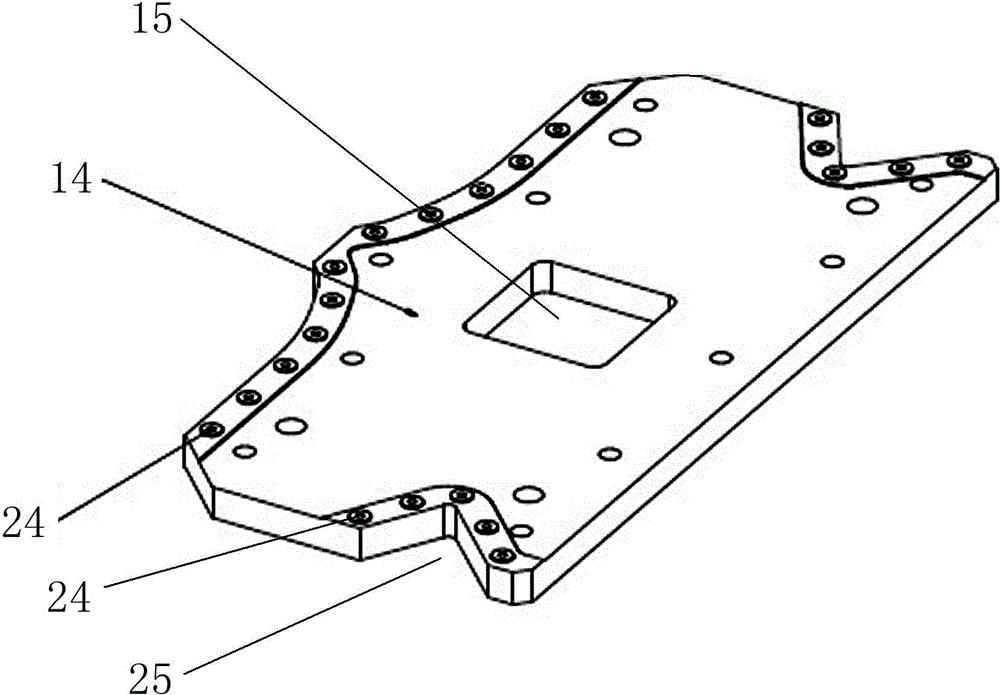

[0013] The invention discloses a blanking die structure, which includes an upper mold base 1 and a lower mold base 2, which is different from the prior art in that two symmetrically distributed The first upper knife block 3 and the second upper knife block 4, the first upper knife block 3 and the second upper knife block 4 form a space 5, and the inner edges of the first upper knife block 3 and the second upper knife block 4 form an arc surface , both sides of the lower surface of the upper mold base 1 are respectively provided with a third upper knife block 6 and a fourth upper knife block 7, the third upper knife block 6 and the fourth upper knife block 7 are in a triangular shape, and the third upper knife block 7 The knife block 6 and the fourth upper knife block 7 are symmetrically distributed, and the upper mold base 1 lower surface between the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com