Machine hand claw capable of entwisting wiring harnesses

A technology of robots and moving wires, applied in the direction of manipulators, circuit/collector components, electrical components, etc., can solve the problems of angle rotation of wire harnesses, achieve precise assembly, reduce labor requirements, and achieve efficient wire harness assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

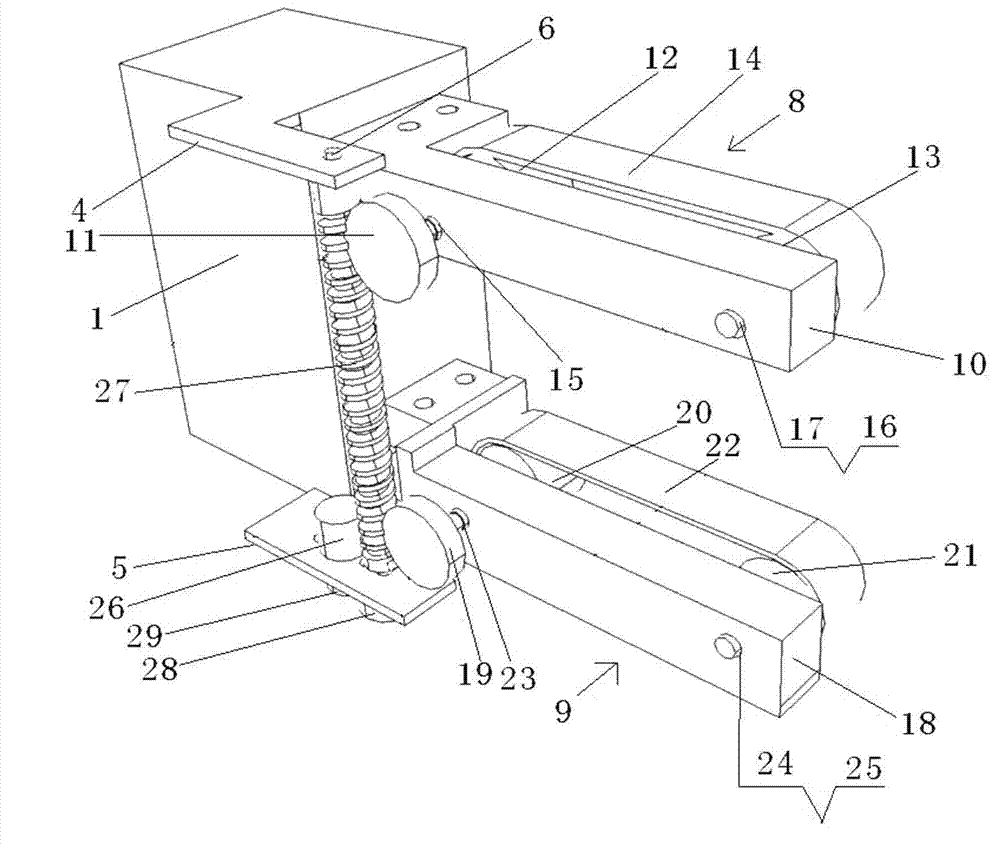

[0015] A robot gripper capable of twisting a wire harness, comprising a manipulator, a worm drive mechanism and twisting fingers;

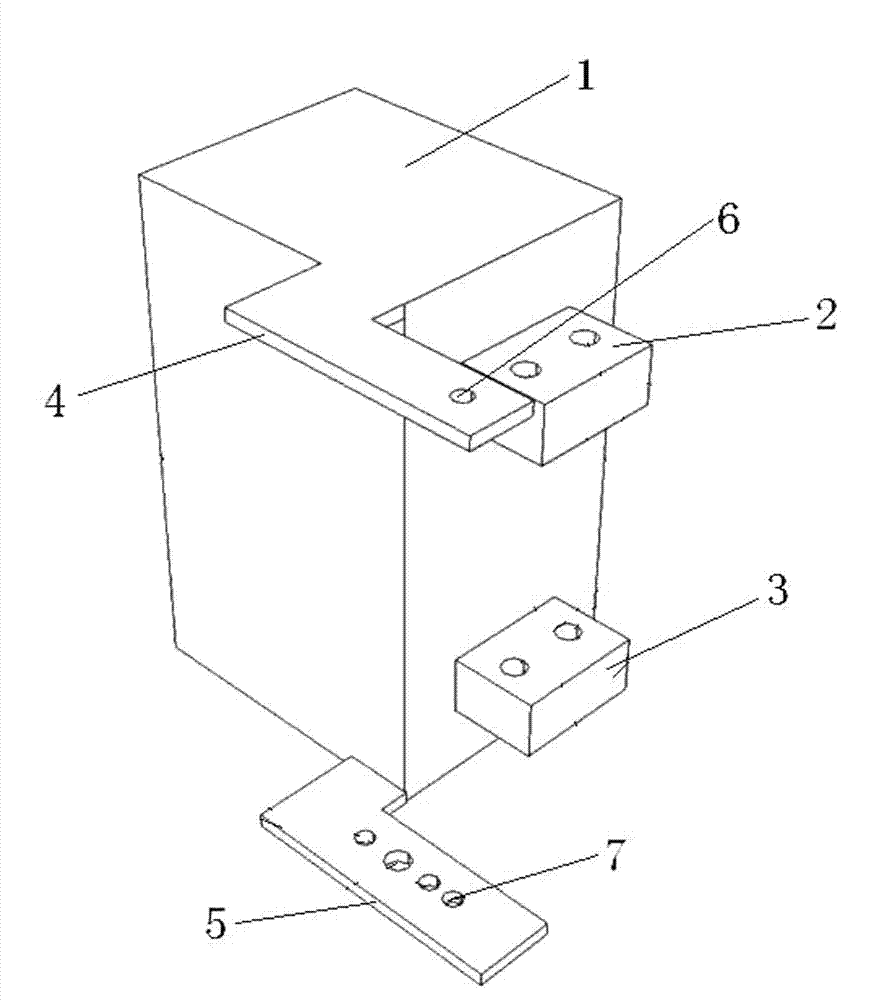

[0016] The manipulator is assembled by the manipulator base 1, the upper parallel movement finger 2 and the lower parallel movement finger 3; the upper end and the lower end of one side of the manipulator base 1 are respectively fixedly equipped with an upper worm support plate 4 and a lower worm support plate 5; The worm support plate 4 is provided with a first worm shaft hole 6, and the lower worm support plate 5 is provided with a second worm shaft hole 7; the upper parallel motion finger 2 and the lower parallel motion finger 3 can move up or down in parallel; the manipulator is Known technology; characterized in that:

[0017] The twirling fingers consist of an upper twirling finger 8 and a lower twirling finger 9 .

[0018] Last twist finger 8 comprises last twist finger base 10, first worm wheel 11, first pulley 12, second pulley 13 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com