Foam cutting machine

A cutting machine and foam technology, applied in the field of mechanical processing, can solve the problems of inconvenient use of saws, etc., and achieve the effect of fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

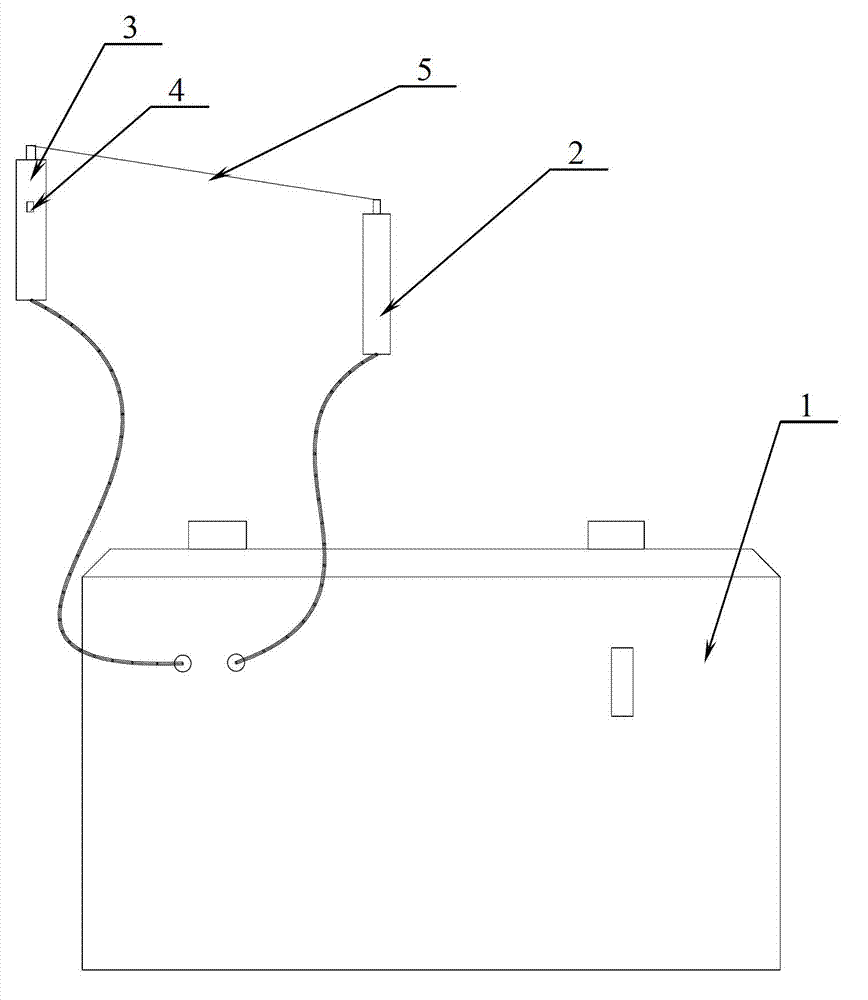

[0011] Example 1, such as figure 1 As shown, this embodiment discloses a foam cutting machine, which includes a transformer 1 connected to a power supply, the transformer, a handle 2, and a weight 3 forming a closed loop, wherein there is a switch 4 on the weight, and The handle and the pendant are connected by resistance wire 5. The length of the resistance wire is adjustable. And there is also a gear on the transformer that can adjust the output voltage level.

[0012] For the foam cutting machine disclosed in this embodiment, as long as the switch on the pendant is turned on, the resistance wire between the handle and the pendant can be energized and heated, and then the foam is cut at high temperature. Influence of properties such as thickness.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap