Bottle blank seating device of bottle blowing machine and bottle blank seating method

A preform holder and blow molding machine technology, applied in the field of blow molding machines, can solve the problems of limited heating quantity, influence on process speed, cost and time impact, and achieve the effect of increasing the heating quantity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

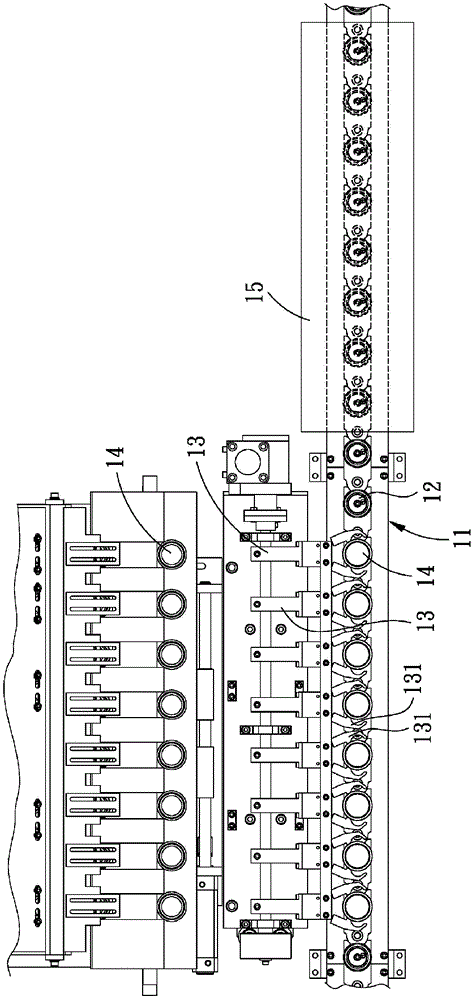

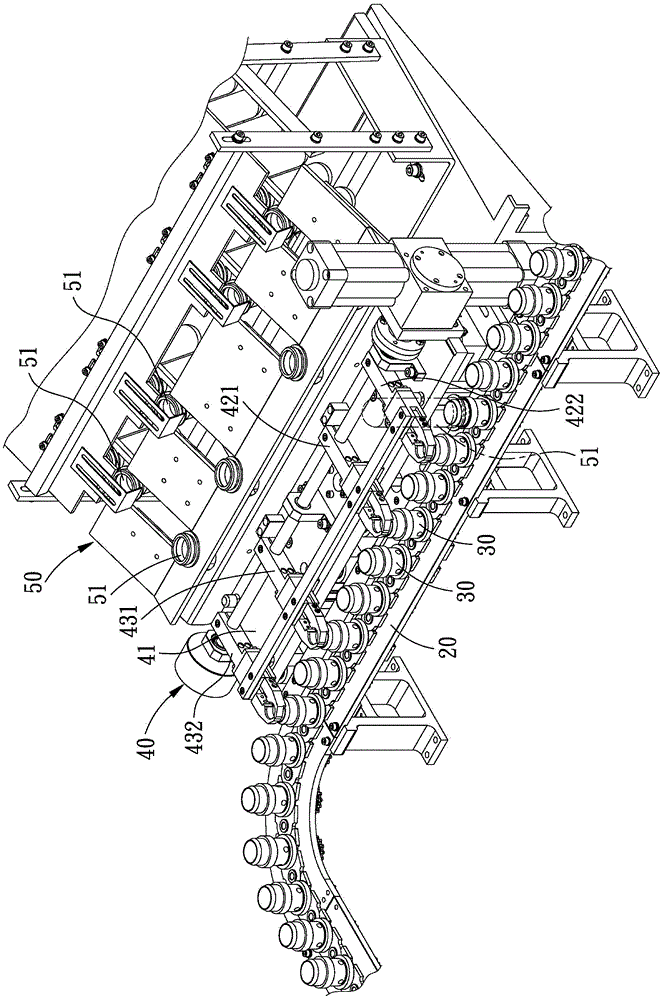

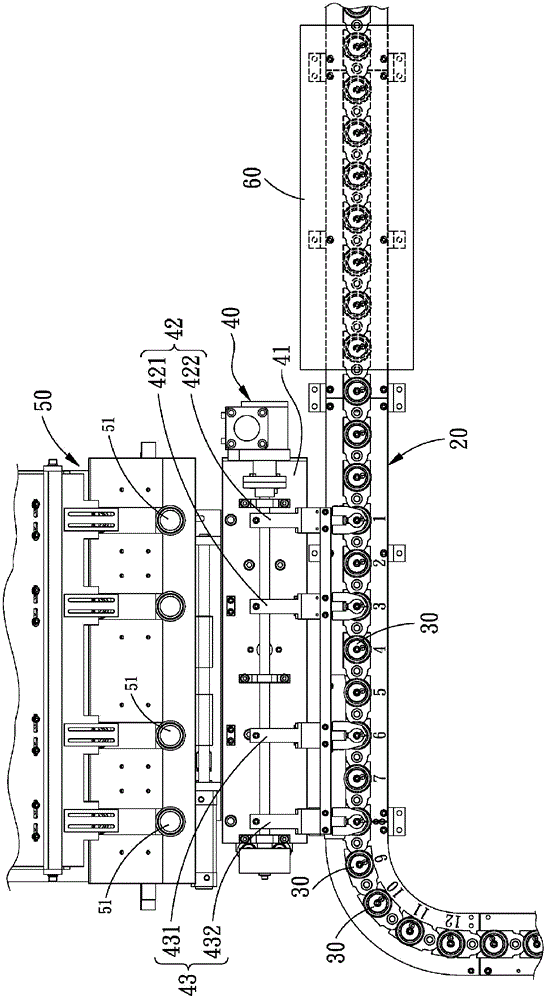

[0023] refer to figure 2 , image 3 , the preform seating device of a bottle blowing machine provided by the first embodiment of the present invention is mainly composed of a rail 20 , a plurality of preform seats 30 , a clamping unit 40 and a supply unit 50 .

[0024] The track 20 is a cyclical action track.

[0025] A plurality of preform holders 30 are equidistantly arranged on the track 20 . In this embodiment, the preform holders 30 are numbered on the figure, and numbered 1 to 12 from right to left.

[0026] The clamping unit 40 is correspondingly arranged on one side of the track 20, and has a platform 41, a first clamping arm set 42 and a second clamping arm set 43 disposed on the platform 41, wherein the first clamping arm set 42 includes a corresponding The first clamping arm 421 of a bottle embryo base 30 (numbering 3) and the second clamping arm 422 that is located at the first clamping arm 421 right side and apart from the first clamping arm 421 a bottle embryo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com