Bonding structure, electronic device with the bonding structure and bonding method thereof

一种电子装置、黏结的技术,应用在电子器材、层压装置、化学仪器和方法等方向,能够解决溢胶、耗费人力、物力等问题,达到降低人力与物力之耗费、减少产品的不良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

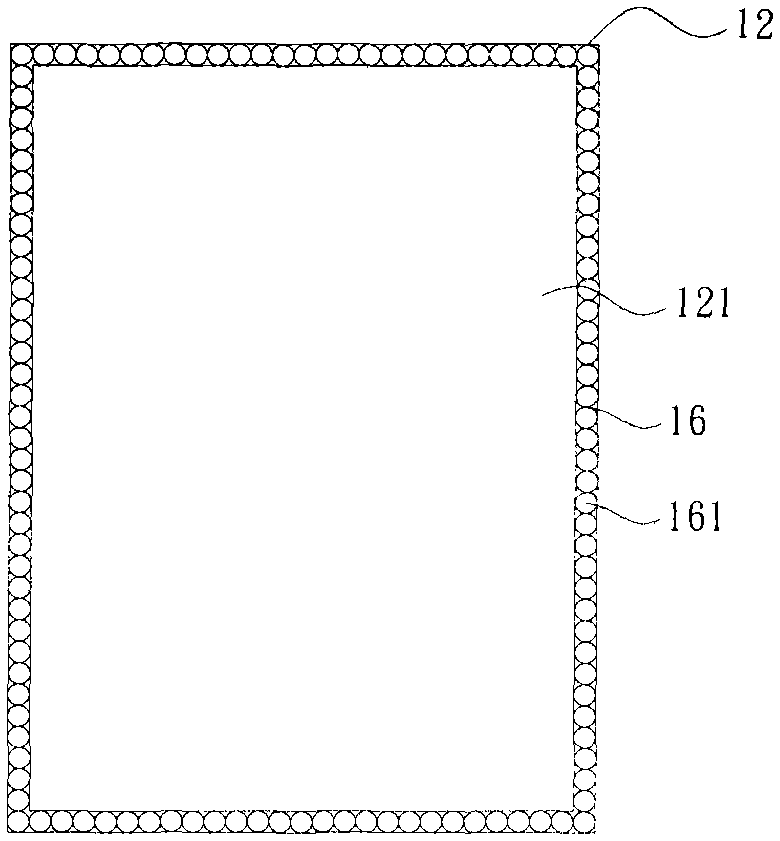

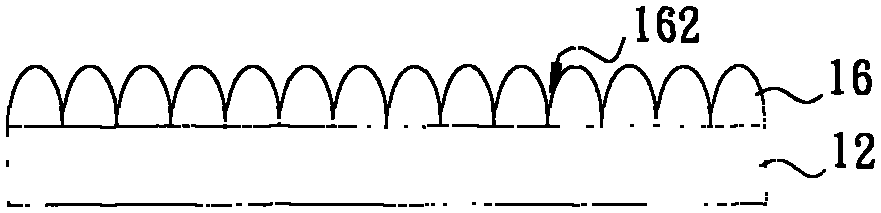

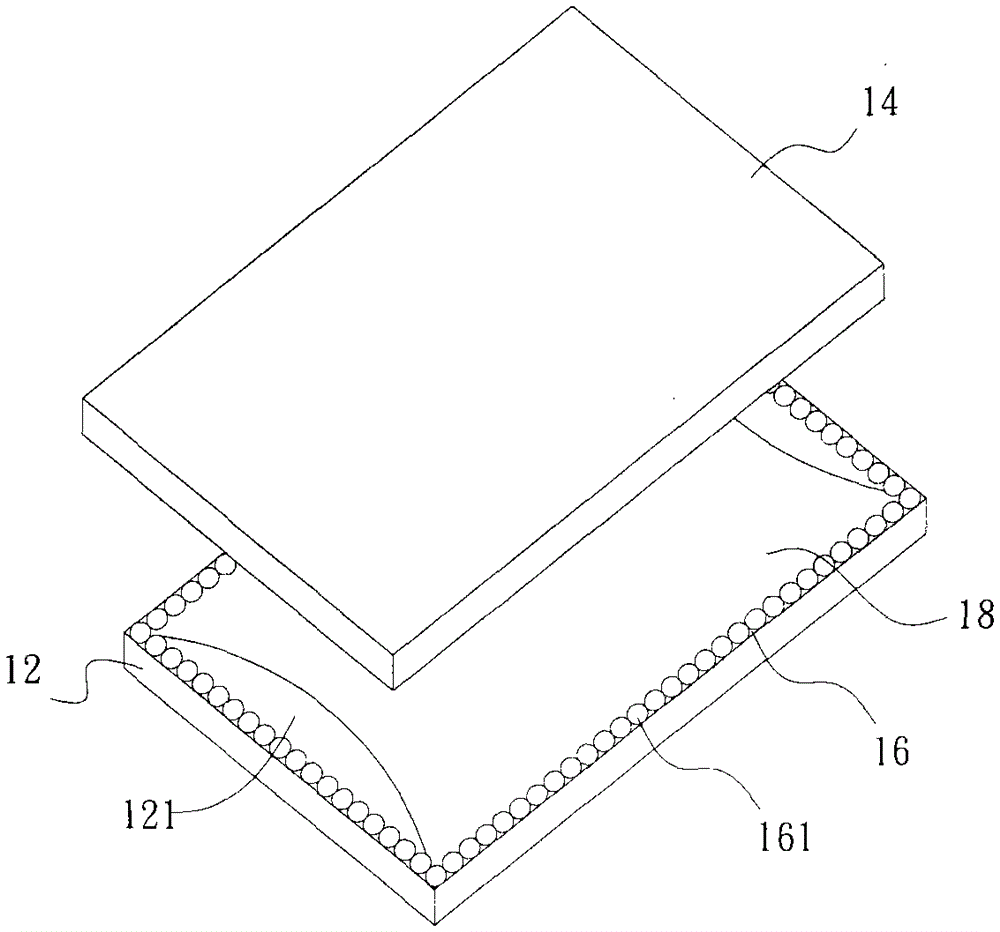

[0021] figure 1 and figure 2 The bonding structure of the present invention is shown. figure 1 It is a top view of the bonding frame formed in the peripheral area of the first substrate of the present invention, figure 2 It is a side view of the bonding frame formed in the peripheral area of the first substrate of the present invention. The bonding structure includes a bonding frame 16, which is arranged on the peripheral area of a first substrate 12, and forms a bonding region 121 on the first substrate 12, which is used for coating liquid adhesive glue, so that the The liquid adhesive glue is filled with the attaching area 121 to form a liquid adhesive layer for attaching another substrate. The adhesive frame 16 is an adhesive of elastic polymer compound (such as epoxy resin or acrylic resin).

[0022] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com