Shock absorber lower connecting assembly

A technology for connectors and shock absorbers, which is applied to vehicle components, elastic suspensions, suspensions, etc., and can solve problems affecting the service life of shock absorbers, the structural strength of connector components under the influence, and the displacement of welding bumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

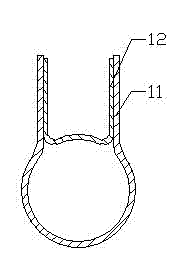

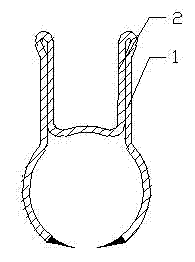

[0010] Such as figure 2 A shock absorber lower connector assembly 3 shown is composed of a lower connector 1 and a reinforcing plate 2, and the lower connector 1 and the reinforcing plate 2 are of an integral structure.

[0011] The integral lower connector component 3 is formed by a stamping process at one time, and the lower connector 1 and the reinforcing plate 2 are designed as an integral blanking during punching and blanking. The integral structure avoids the process of projection welding and pre-punching bumps before the existing lower connector components, simplifies the processing procedure, and eliminates the cumulative error caused by multiple processing procedures, making the lower connector The molding quality of component 3 is stable and consistent.

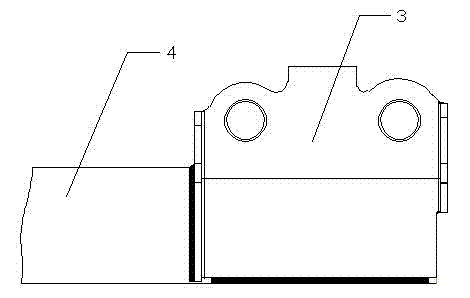

[0012] Such as figure 2 and 3 As shown, since the lower connector assembly 3 is an integral structure, the structural strength of the lower connector assembly 3 is enhanced, and only the integral lower connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com