A glass panel cutting apparatus comprising double controllers

A glass panel and cutting device technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve problems such as inability to ensure system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

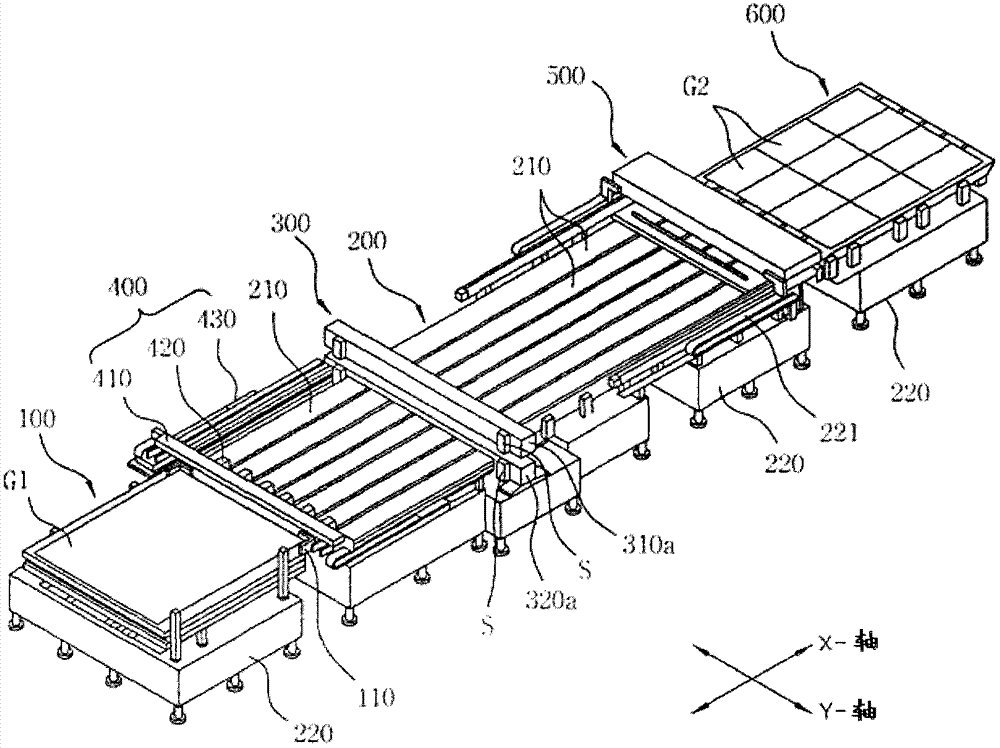

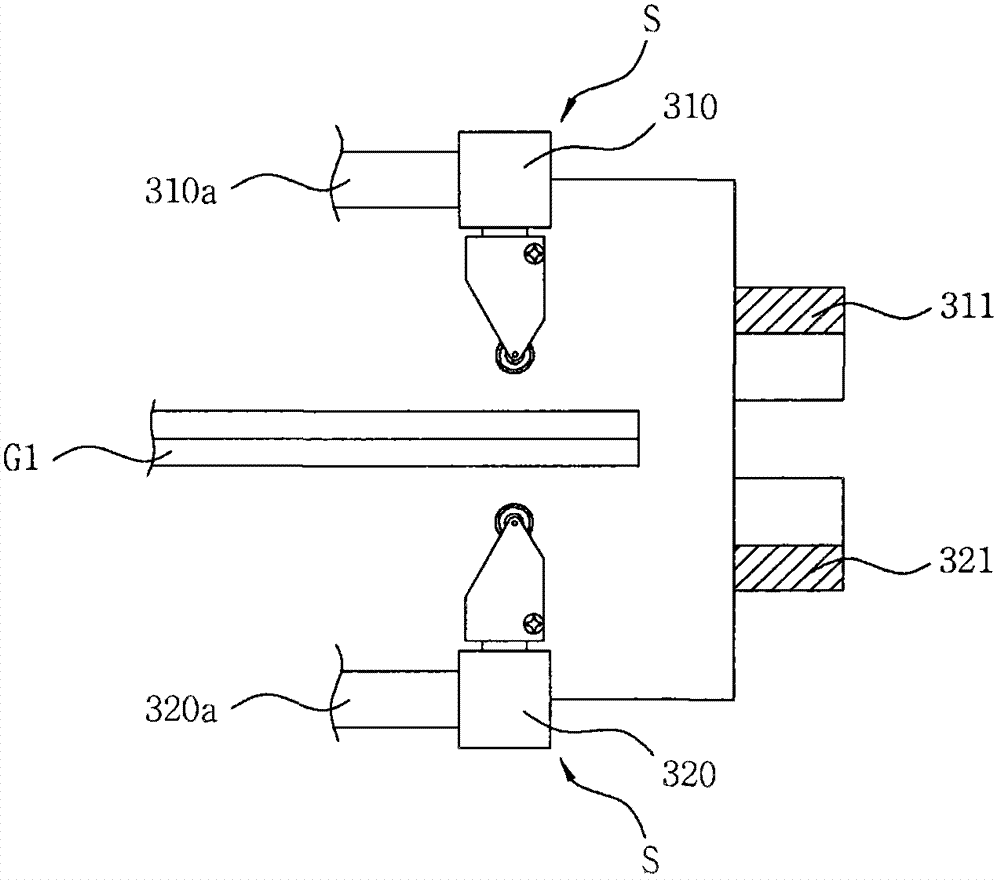

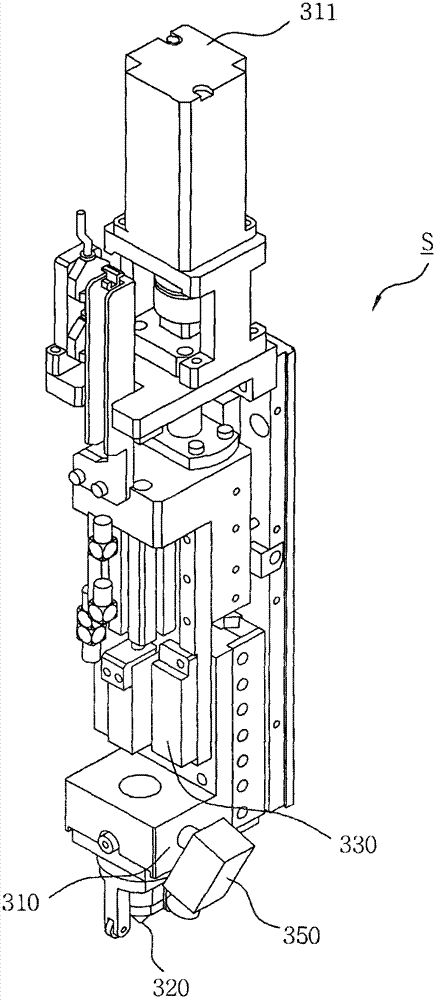

[0025] figure 1 is a perspective view showing a glass panel cutting device according to an embodiment of the present invention. figure 2 is showing figure 1 Side view of the construction of the load cell and scribing device. image 3 is showing figure 2 perspective view of the scribing device. Figure 4 is a view showing a control structure of a glass panel cutting device having a dual controller according to the present invention. Figure 5 is showing Figure 4 Constructed view of the dual controller.

[0026] Such as figure 1 As shown, the glass panel cutting system includes a loading unit 100 , a glass panel conveying unit 200 , a scribing unit 300 and a gripper unit 400 . The glass panel G1 to be cut into a plurality of unit glass panels G2 is loaded on the loading unit 100 . The glass panel conveying unit 200 conveys and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap