A stainless steel pull sling device for a bridge

A technology of stainless steel and pulling slings, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of cumbersome connection relations, unfavorable engineering maintenance, and too many parts, so as to improve the cumbersome structure, facilitate maintenance and repair, reduce Economic cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be specifically described through exemplary embodiments. It is to be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

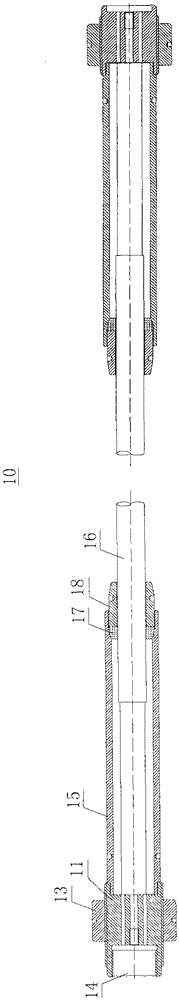

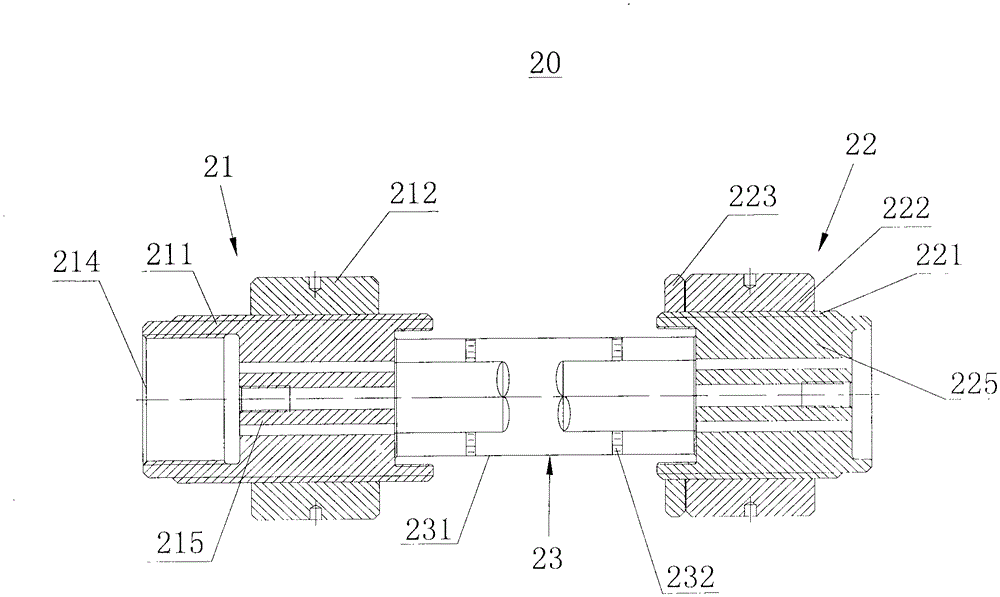

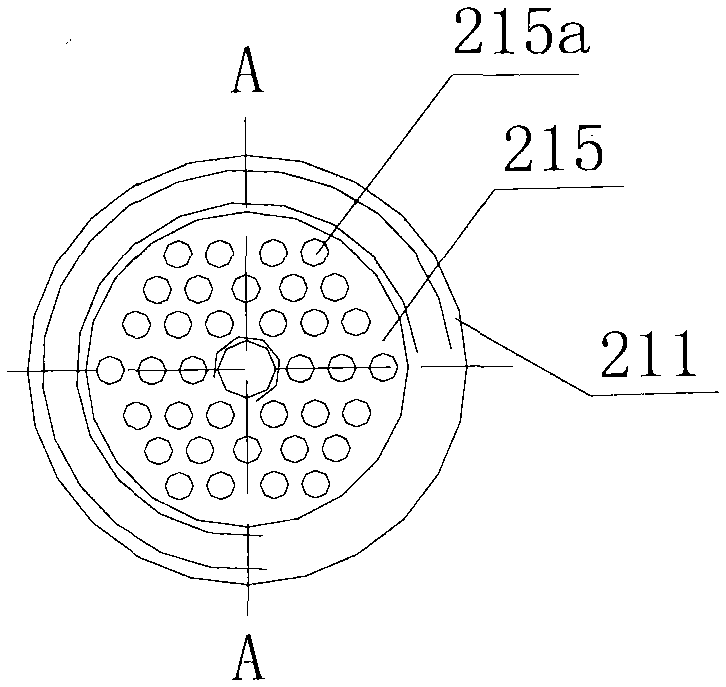

[0026] see figure 2 , shows a stainless steel pull-sling device 20 for a bridge according to an embodiment of the present invention, which is arranged on a pull-sling bridge. Specifically, the pull sling device 20 includes: a pull cable for bearing tension, and the pull cable is formed by a collection of stainless steel wires; a tension end anchor 21 and a fixed end anchor 22 are respectively used to cooperate with anchors on the pull cable. The two ends are used to transmit the cable force of the stay cable; and the guard 23 is connected between the anchor 22 at the fixed end and the anchor 21 at the tension end, and is used to protect the exposed part of the stay cable outside the anchor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com