Tail pipe completion method by plugging expandable casing on top of screen pipe

A technology of expandable casing and screen pipe, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc. It can solve the problem of performance and quality affecting the smooth progress and success of construction, affecting the quality of well completion, and supporting tools Complicated problems, to achieve good sealing suspension function, facilitate oil production and operation, and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

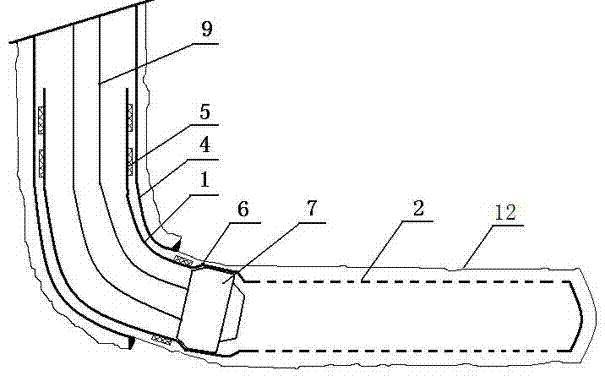

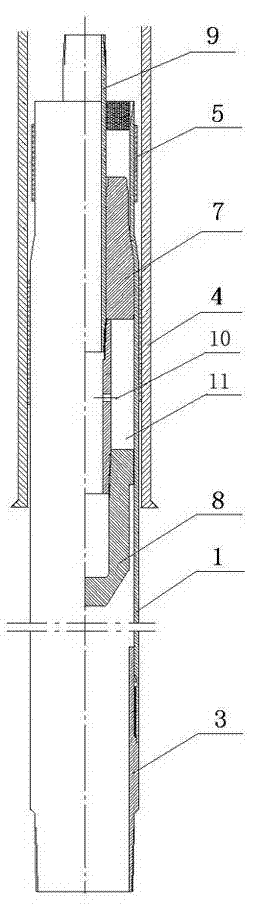

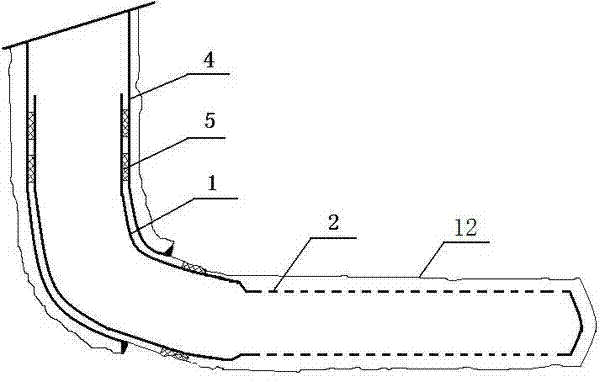

[0018] A liner completion method for plugging the top of the screen with an expandable casing. The method for plugging the top of the screen is mainly described through the expansion casing and the setting and hanging system of the expandable casing. First, run the screen and expansion casing to the designed well depth according to conventional methods; The hanging tool forms a sealed chamber, and the liquid is continuously pumped into the central tube, and the pressure in the sealed chamber is continuously increased, pushing the expansion cone to move from bottom to top, expanding the expansion sleeve and the rubber ring, and the rubber ring is compressed between the expansion sleeve and the technology. In the annular space between the casings, or compressed in the annular space between the expansion casing and the open hole wall, a suspension and sealing device are formed, thereby achieving the purpose of isolating complex layers and preventing the liner string from channelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com