Oil scraper ring

A technology of oil scraper ring and oil ring sheet, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, machines/engines, etc., can solve problems such as waste, piston rings, packing wear, gas pollution, etc., and achieve leakage Oil problem, avoid relative rotation, effect of increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

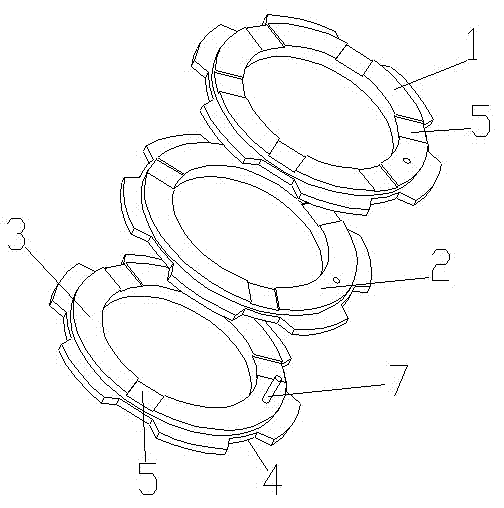

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 It is an oil scraper ring according to the present invention, which includes an oil scraper ring piece and a positioning pin 6 arranged in the oil scraper ring piece. 2 and the lower end oil scraper ring 3; the oil scraper ring is provided with an oil return groove 4 with a width of 12-16 mm to increase the area of the oil return channel; the middle end oil scraper ring 2 and the lower end oil scraper ring There are three oil grooves 5 with a width×depth of 16mm×1.5mm on the piece 3, and six oil grooves 5 of 16mm×1.5mm on the upper oil scraper ring piece 1. Through the design of the oil groove 5, the end face The oil can flow back in time and quickly; positioning pins 6 are arranged between the upper oil scraper ring 1, the middle oil scraper ring 2 and the lower oil scraper ring 3 to prevent relative rotation of the oil scraper rings, overlapping openings, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com