Rotary compressor

A technology of rotating compressors and rotors, used in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of reduced crankshaft reliability, noise, abnormal compressor vibration, etc., and achieve the effect of ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

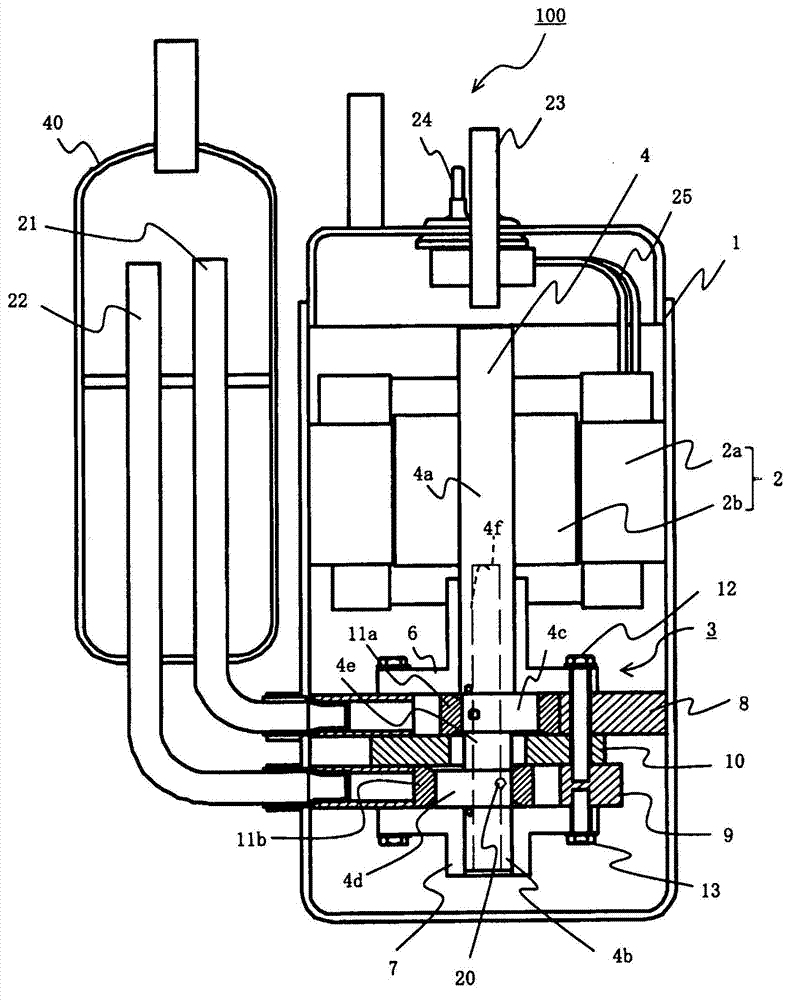

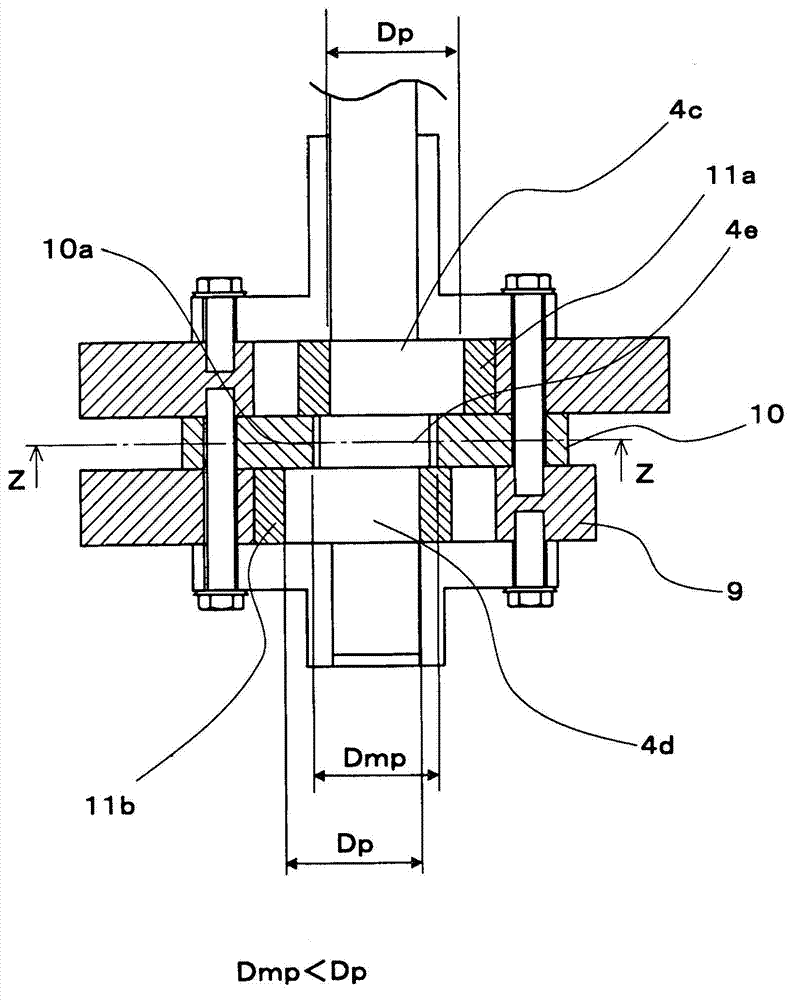

[0018] Figure 1 to Figure 6 is a diagram showing Embodiment 1, figure 1 is a longitudinal sectional view of the twin-cylinder rotary compressor 100, figure 2 and image 3 is a longitudinal sectional view of the compression mechanism part 3 of the two-cylinder rotary compressor 100, Figure 4 yes figure 2 The Z-Z section view in, Figure 5 It is a figure showing the procedure of assembling the first piston 11a to the crankshaft 4 when the relief shape 11a-1 is provided at both axial ends of the inner diameter of the first piston 11a, Figure 6 is a comparison Figure 5 and Figure 7 of the graph ( Figure 6 (a) represents a comparative example, Figure 6 (b) represents this embodiment).

[0019] Below, use Figure 1 to Figure 6 The twin-cylinder rotary compressor 100 according to Embodiment 1 will be described.

[0020] use figure 1 The configuration of the two-cylinder rotary compressor 100 will be described. A motor 2 including a stator 2 a and a rotor 2 b and...

Embodiment approach 2

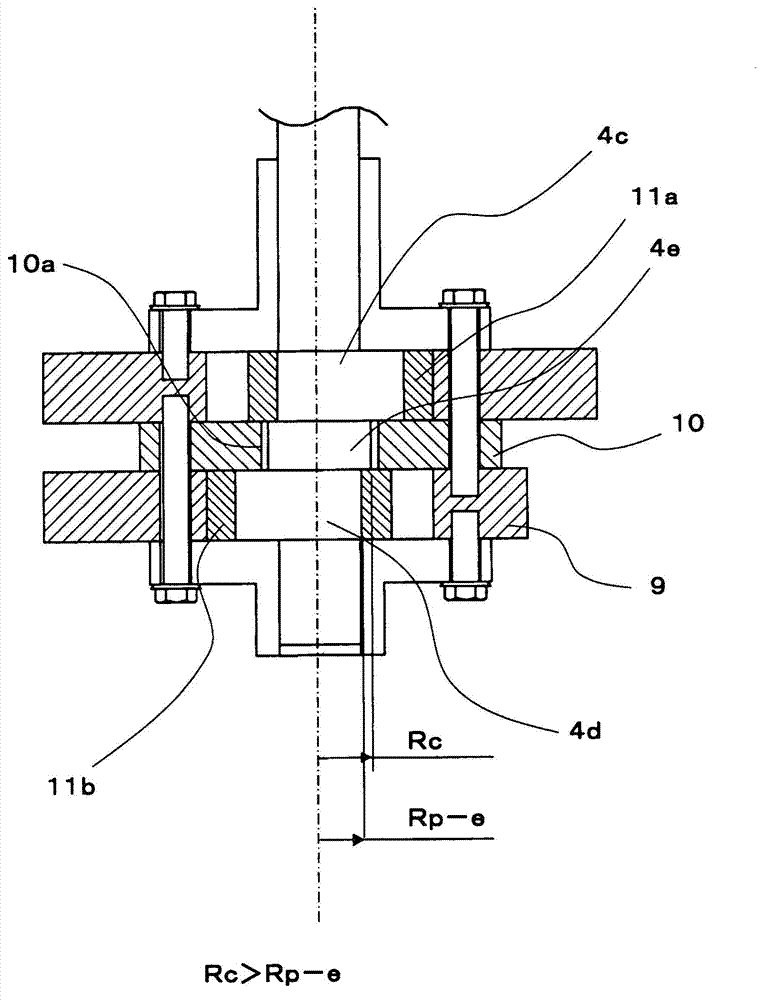

[0080] In Embodiment 1, the relationship between the inner diameter 10 a of the separator 10 and the first piston 11 a and the second piston 11 b is not particularly mentioned. The inner diameter 10 a of the separator 10 and the first piston 11 a and the second piston 11 b may be formed in, for example, the following relationship. In addition, items that are not particularly described in the second embodiment are the same as those in the first embodiment, and the same functions and configurations will be described using the same reference numerals.

[0081] Figure 8 It is a figure which shows Embodiment 2, and is a longitudinal cross-sectional view of the compression mechanism part 3 of the twin-cylinder rotary compressor 100. As shown in FIG.

[0082] Such as Figure 8 As shown, if the distance from the axial center of the intermediate shaft 4e to the inner peripheral surface of the inner diameter 10a of the separator 10 (that is, the radius of the inner diameter 10a of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com