Clutch relay device

A clutch and meshing technology, applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of chasing gear tail, dual drive asynchrony, disengagement, etc., to achieve stable engagement state and smooth meshing process. The effect of smooth and smooth transition of the relay process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

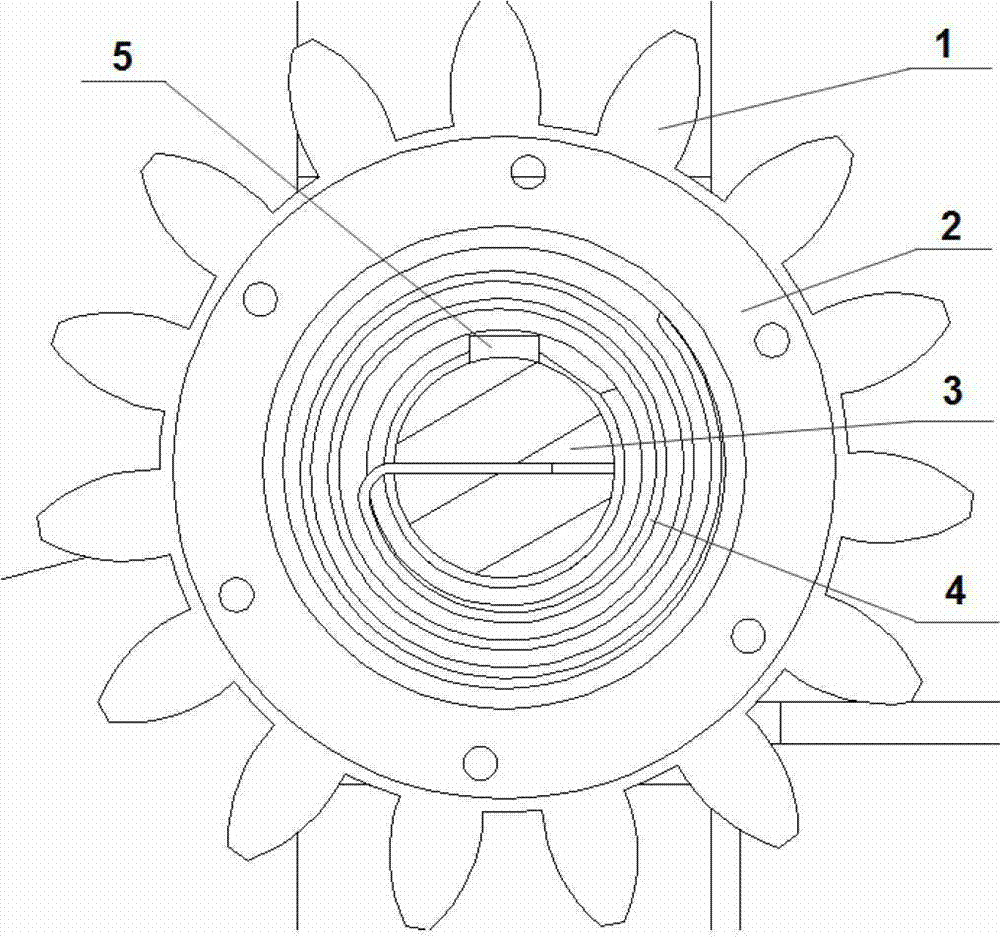

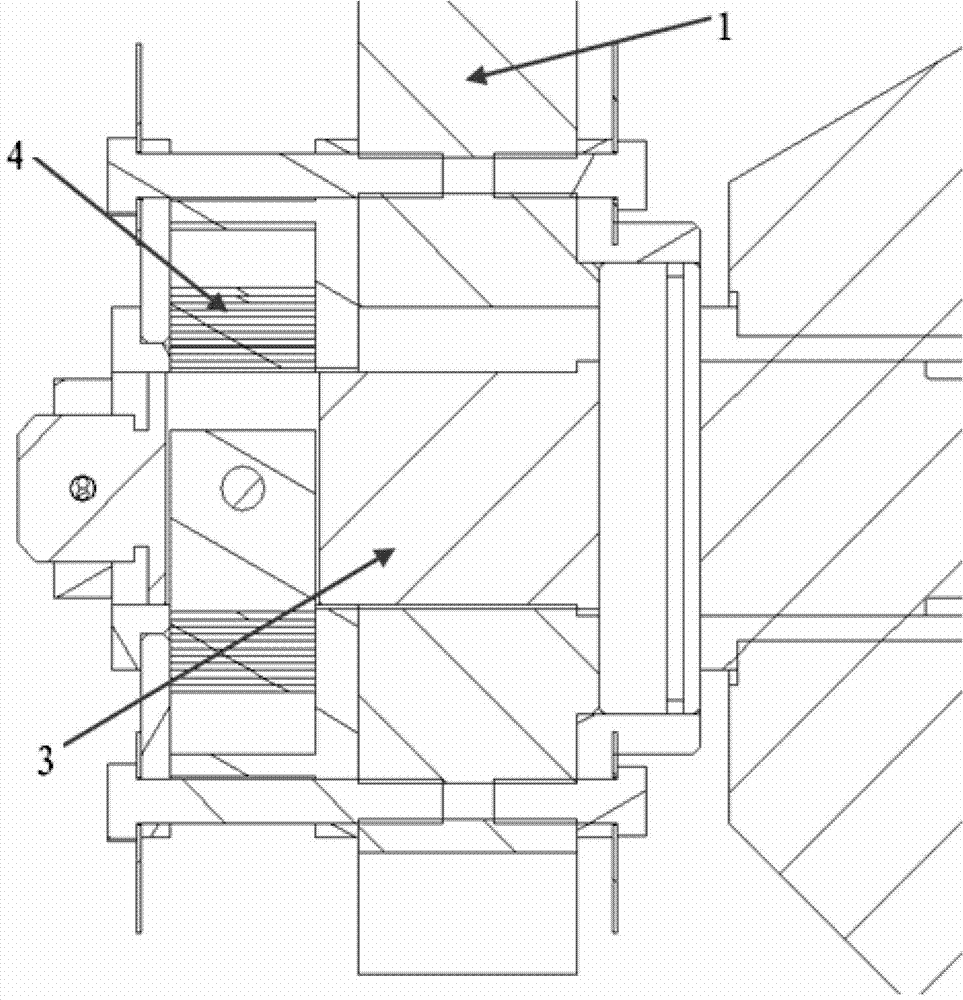

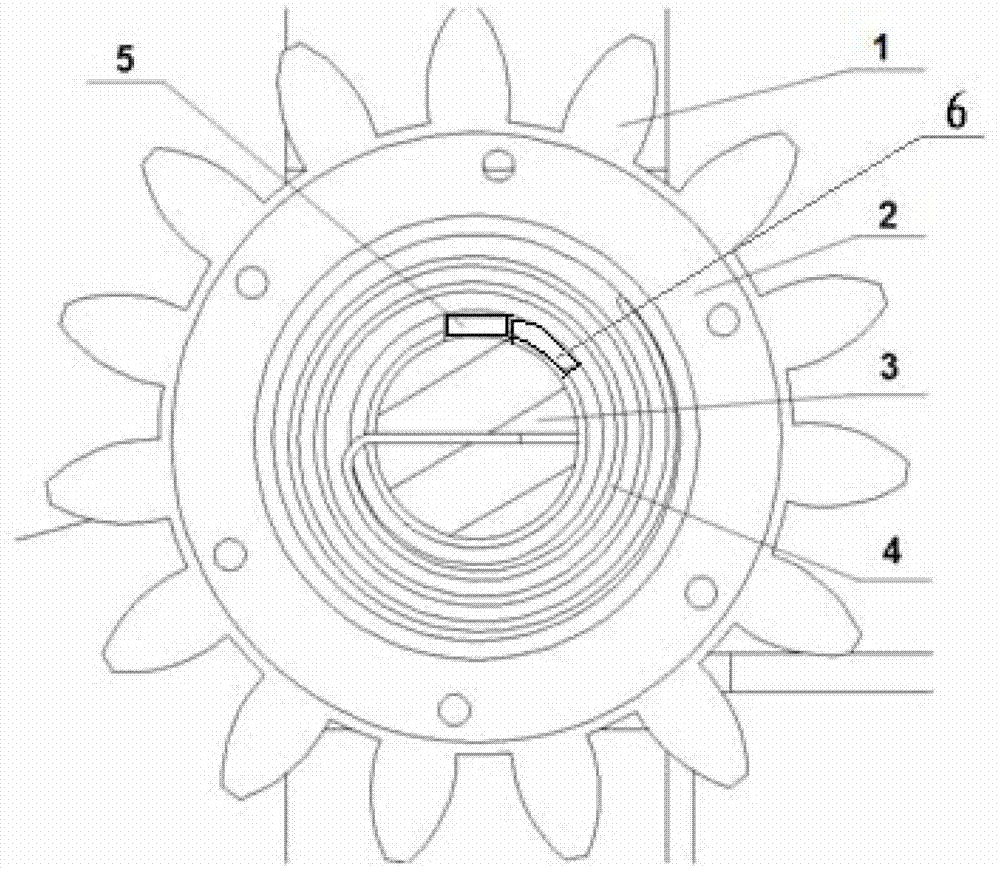

[0030] In this embodiment, the clutch relay device is installed on the lower transmission mechanism of the fuel transfer device (installed on both sides of the reactor building and the fuel building respectively), such as Figure 5 , Figure 6 and Figure 7 As shown, the transmission mechanism transmits the motor torque through the coupling, the bevel gear, and the drive shaft 3. The gear 1 is seated on the rolling bearing of the drive shaft 3 through the connecting sleeve, and the gear 1 meshes with the rack on the transport trolley. , to drive the trolley forward and backward. In the process of relay driving, the rack is driven by one gear in most cases, and only when the transport trolley is about to pass through the fuel transfer channel (two-way), there is a case where one rack contacts two gears at the same time .

[0031] In this embodiment, the working process of the driving transfer device of the clutch relay device can be basically divided into four states, as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com