High-temperature muffle furnace nine-time thermometry

A nine-point temperature measurement and muffle furnace technology, which is applied in the field of high-temperature muffle furnace nine-point temperature measurement method, can solve the problems of large temperature difference in the constant temperature zone of the high-temperature muffle furnace, large fluctuations in aging tests, and large actual temperature deviations. Achieve the effects of saving test time, reliable temperature data support, and avoiding abnormal fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: set the critical temperature as 1300°C and the aging temperature as 1050°C.

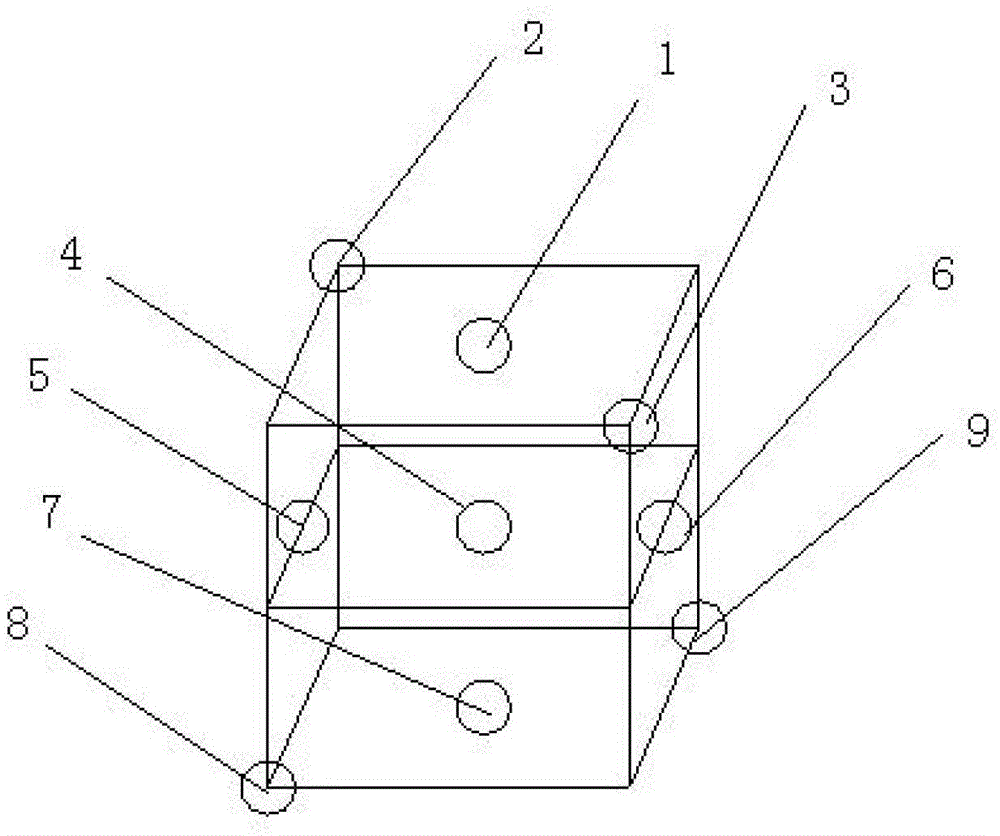

[0020] (1). Take points: such as figure 1 As shown, a ceramic sheet is fixed at the center of the furnace mouth of the high-temperature muffle furnace, and the first temperature calibration ring 1 is placed on the ceramic sheet as the first temperature measurement point. A ceramic sheet is respectively fixed at both ends of the furnace mouth of the high-temperature muffle furnace. The second temperature calibration ring 2 and the third temperature calibration ring 3 are respectively placed on the two ceramic sheets as the second temperature measurement point and the third temperature measurement point; a ceramic sheet is fixed in the center of the middle part of the high temperature muffle furnace, and the ceramic The fourth temperature calibration ring 4 is placed on the chip as the fourth temperature measurement point. A ceramic sheet is respectively fixed at both ends of the m...

Embodiment 2

[0063] Embodiment 2: set the critical temperature as 1250°C and the aging temperature as 950°C.

[0064] (1). Take points: such as figure 1 As shown, a ceramic sheet is fixed at the center of the furnace mouth of the high-temperature muffle furnace, and the first temperature calibration ring 1 is placed on the ceramic sheet as the first temperature measurement point. A ceramic sheet is respectively fixed at both ends of the furnace mouth of the high-temperature muffle furnace. The second temperature calibration ring 2 and the third temperature calibration ring 3 are respectively placed on the two ceramic sheets as the second temperature measurement point and the third temperature measurement point; a ceramic sheet is fixed in the center of the middle part of the high temperature muffle furnace, and the ceramic The fourth temperature calibration ring 4 is placed on the chip as the fourth temperature measurement point. A ceramic sheet is respectively fixed at both ends of the mi...

Embodiment 3

[0107] Embodiment 3: set the critical temperature as 1200°C and the aging temperature as 1000°C.

[0108] (1). Take points: such as figure 1 As shown, a ceramic sheet is fixed at the center of the furnace mouth of the high-temperature muffle furnace, and the first temperature calibration ring 1 is placed on the ceramic sheet as the first temperature measurement point. A ceramic sheet is respectively fixed at both ends of the furnace mouth of the high-temperature muffle furnace. The second temperature calibration ring 2 and the third temperature calibration ring 3 are respectively placed on the two ceramic sheets as the second temperature measurement point and the third temperature measurement point; a ceramic sheet is fixed in the center of the middle part of the high temperature muffle furnace, and the ceramic The fourth temperature calibration ring 4 is placed on the chip as the fourth temperature measurement point. A ceramic sheet is respectively fixed at both ends of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com