Cantilever type moving train axle load test method and test device thereof

A test device and cantilever technology are applied in the field of cantilever mobile train axle load test method and test device, which can solve the problems of restricting research progress, lack of test verification, rare overturning resistance test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

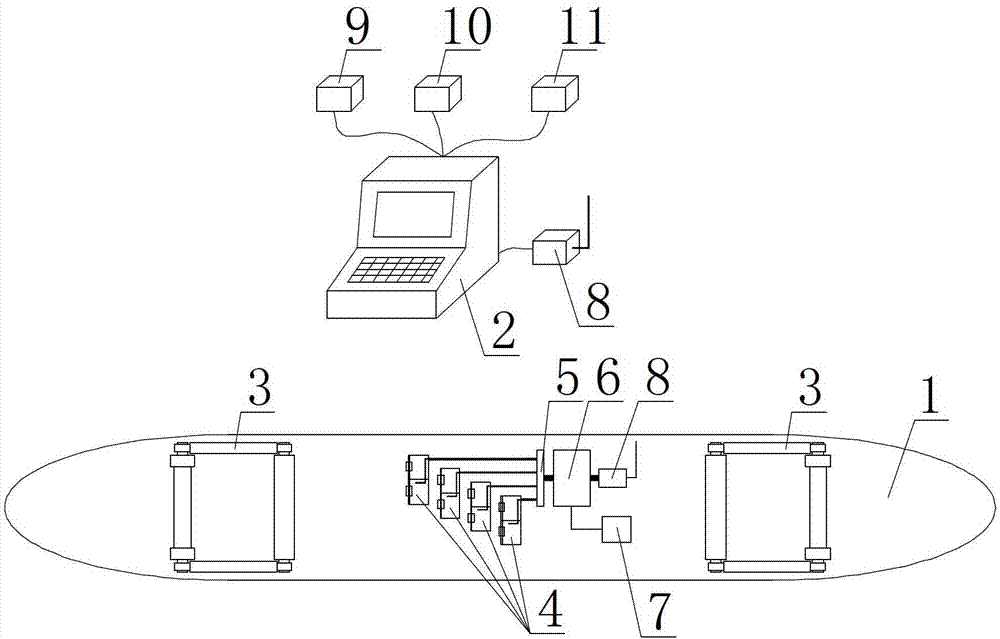

[0025] A concrete implementation of a cantilever type mobile train axle load testing method, the steps are as follows:

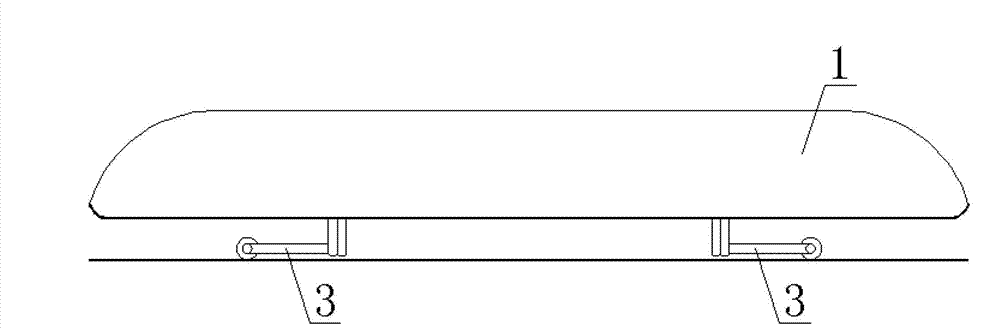

[0026] (1) There are four parallel shafts at the bottom of the CRH high-speed train model, and the middle two shafts among the four shafts of the CRH high-speed train model are fixed on the bottom of the CRH high-speed train model;

[0027] (2) One end of the special flat cantilever beam is fixedly connected to the fixed shaft in the middle, and the other end is connected to the corresponding outer shaft;

[0028] (3) The axial force is reflected by testing the deformation of the cantilever beam, and the correlation is determined by calibration (need to explain);

[0029] (4) The deformation of the cantilever beam is tested by arranging strain gauges, and the strain gauges are controlled wirelessly for testing, and the axle load time history curve of the moving train is recorded in real time;

[0030] (5) Through the comparison of the time history of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com